Resources

Glossary

Acheson Process

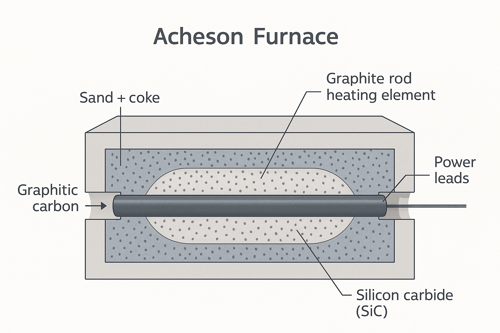

The Acheson process is an industrial method developed by Edward Goodrich Acheson in 1891 to produce silicon carbide (SiC) and later adapted for synthetic graphite. It uses an electric resistance furnace to reach extremely high temperatures and allows large-scale, economical production of these materials, which became crucial to abrasives and electrical industries.

In the process, a mixture of silica (sand) and carbon, usually in the form of petroleum coke, is packed around a graphite rod that serves as the heating element. When electric current passes through, the resistance generates intense heat—typically around 2,000–2,500 °C. At these temperatures, carbon acts both as a reducing agent and as a conductor of heat. The silica reacts with the carbon to form silicon carbide crystals while releasing carbon monoxide gas.

Close to the hottest zones of the furnace, some of the silicon carbide further decomposes, and the leftover carbon reorganizes into graphitic carbon. This provided Acheson with the first method of producing synthetic graphite, which later became essential for electrodes, refractories, lubricants, and batteries.

The Acheson process is significant because it made the commercial production of abrasives such as silicon carbide grinding wheels and sandpapers practical, while also creating a reliable source of synthetic graphite. Both materials are still widely used today: silicon carbide as an abrasive and semiconductor material, and graphite in steelmaking, batteries, and high-temperature industrial applications.

Acid Pickling

Acid pickling is a metal surface treatment process that uses acidic solutions to remove impurities, such as rust, scale, oxides, and other contaminants, from the surface of metals—most commonly steel, stainless steel, aluminum, and copper alloys. The goal of pickling is to produce a clean, reactive metal surface that’s suitable for further processing, such as coating, plating, welding, or forming.

During acid pickling, the metal is immersed in or sprayed with a chemical bath containing acids such as hydrochloric acid (HCl), sulfuric acid (H₂SO₄), nitric acid (HNO₃), or hydrofluoric acid (HF), depending on the metal type and contaminants being removed. The acid reacts with the oxides and corrosion products on the surface, dissolving them and leaving behind bare metal.

In the case of stainless steel, a combination of nitric and hydrofluoric acids is often used to remove heat tint and oxides that form during welding or heat treatment, restoring the alloy’s natural corrosion resistance by promoting the formation of a new, uniform passive oxide layer afterward.

After pickling, the metal is thoroughly rinsed with water to remove any residual acid, and often neutralized with an alkaline solution to stop further chemical reaction.

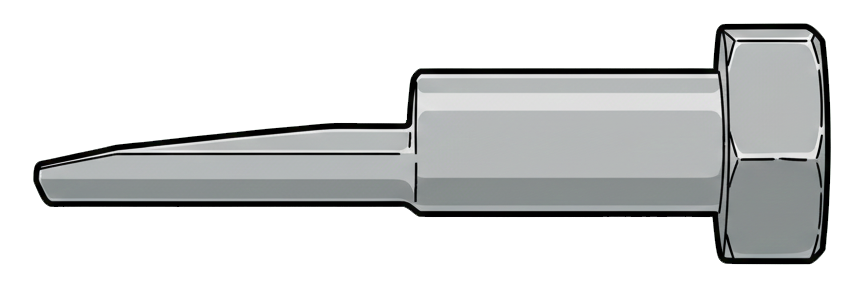

Acme Threads

Acme threads are a type of screw thread profile characterized by their trapezoidal shape, designed to provide high strength, smooth motion, and good load-carrying capability. They are most commonly used in lead screws, vises, jacks, and machinery where power transmission and precise linear motion are required rather than simple fastening.

The Acme thread form has a 29° included angle (with 14.5° on each side) and flat crests and roots, which make it stronger and more durable than traditional V-threads. The broader, flatter surfaces distribute loads more evenly and resist wear under heavy use, making them ideal for translating rotational motion into linear movement in mechanical assemblies.

There are two main types of Acme threads: General Purpose (GPA), used for standard power screws, and Centralizing Acme, which maintains better alignment between mating parts under heavy side loads. In addition, Stub Acme threads have a shallower profile for applications where space or weight is limited.

Acme threads are typically found in lathe lead screws, bench vises, linear actuators, and industrial presses, where they offer a balance of efficiency, strength, and manufacturability.

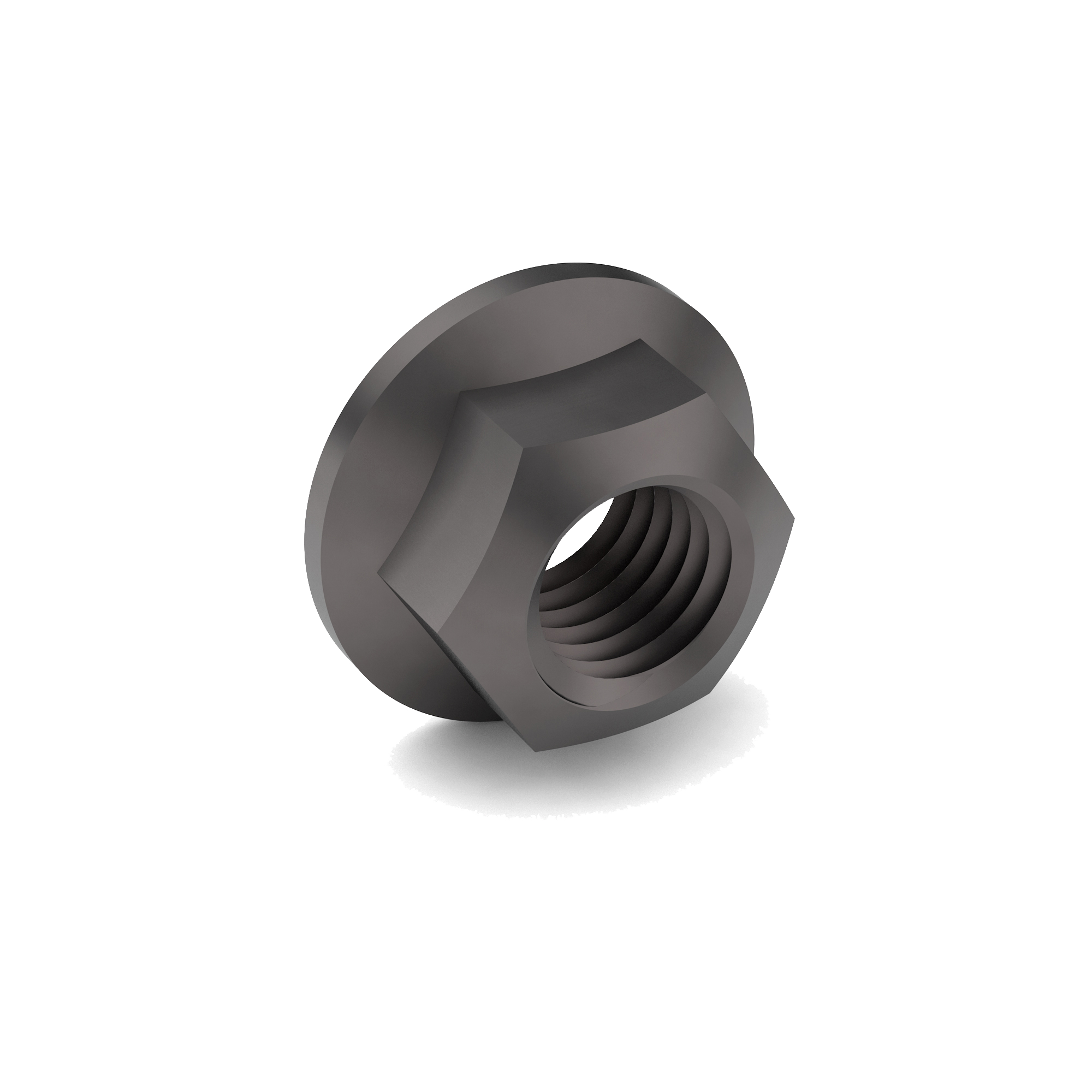

Acorn Cap Nut

An acorn cap nut, often simply called an acorn nut or sometimes a dome nut, is a type of fastener distinguished by its smooth, rounded, dome-shaped head on one end and internal threading on the other. The dome completely covers the exposed end of the bolt or screw, which gives the assembly a neat, finished appearance while also providing functional protection.

The primary purpose of the acorn cap nut is to cover and protect the exposed threads of a bolt or stud. By enclosing the threads, it prevents damage from impact, corrosion, or dirt while also reducing the risk of injury from sharp or abrasive thread ends. This makes acorn nuts especially common in applications where aesthetics, safety, or protection are priorities.

Acorn cap nuts are commonly manufactured from steel, stainless steel, brass, or nylon, and they may be finished with coatings such as chrome plating, zinc plating, or nickel to improve corrosion resistance and appearance. Stainless steel versions are often used in outdoor or marine environments, while chrome-plated brass versions are widely used where decorative appeal is important, such as in furniture, automotive trim, or architectural applications.

These nuts are frequently found in automotive, machinery, furniture, and consumer products, serving both practical and decorative functions. In automotive applications, for example, they are often used on wheel assemblies and body parts where protection and appearance both matter. In furniture or architectural uses, the rounded dome gives a clean and finished look that conceals otherwise exposed bolt ends.

AKA: Acorn Nut, Dome Nut

Acoustical Wedge Anchor

An Acoustical Wedge Anchor is a mechanical expansion anchor designed to secure fixtures, equipment, or assemblies into concrete, masonry, or other solid base materials while addressing the need for soundproofing and vibration control. They are commonly used in the installation of acoustical ceiling systems, wall panels, sound baffles, and vibration-isolated equipment.

These anchors work similarly to standard wedge anchors. Each one consists of a threaded stud with a conical end and an expansion clip. When driven or tightened into a pre-drilled hole, the clip expands outward against the walls of the hole, locking the anchor firmly in place. What makes an acoustical wedge anchor distinct is its ability to minimize vibration transfer and noise transmission. This is typically achieved through the use of special sleeves, bushings, or isolation components that reduce the direct transfer of sound and vibration from the mounted object into the structure.

Acoustical wedge anchors offer several important benefits. They provide a strong mechanical hold with high pull-out strength in solid base materials such as concrete. They also offer vibration and noise reduction, making them ideal for sound-sensitive installations. In addition, they are known for their durability, since they are usually made from zinc-plated or stainless steel, and they come in a variety of diameters and lengths to meet different load requirements.

Because of these qualities, acoustical wedge anchors are widely used across multiple applications. In acoustical ceilings, they secure suspension systems for drop ceilings that require soundproofing. For sound panels and baffles, they are used in theaters, auditoriums, and recording studios to mount panels effectively. They also play a role in mechanical and electrical systems, anchoring vibration-isolated hangers, conduits, and piping in environments where noise reduction is important. Finally, in industrial settings, they are used to mount machinery and equipment where controlling vibration is critical for both noise management and proper performance.

Adhesive Anchor

An adhesive anchor is a type of post-installed fastener used to connect metal to concrete, masonry, or stone, or to attach new concrete to existing concrete. Unlike mechanical anchors that use friction or expansion to hold in place, adhesive anchors create a strong bond between the anchor element (like a threaded rod or rebar) and the base material.

The process involves drilling a hole, thoroughly cleaning it to remove any dust or debris, and then injecting a chemical adhesive (either from an injectable cartridge or a capsule) into the hole. The anchor element is then inserted, and as the adhesive cures through a chemical reaction, it bonds to both the anchor and the surrounding base material. This method spreads the stress and load along the entire length of the anchor, which reduces the risk of cracking the base material, making it suitable for both strong and weak concrete.

Adhesive anchors are often used in situations where cast-in anchors are missing or misaligned, or in retrofit projects. They are valued for their high performance, flexibility with edge and anchor spacing, and versatility across various applications, including bridges, guardrails, light poles, and structural repairs.

Adhesive Mount Nut

An adhesive mount nut is a type of fastener base that can be bonded directly to a surface using an industrial adhesive or double-sided mounting tape, instead of requiring a drilled hole or welding. It provides a threaded attachment point—usually a nut or stud—on surfaces where traditional mechanical fastening methods aren’t possible or desired.

The design typically consists of a metal or plastic base plate with a pre-attached nut or threaded insert in the center. The underside of the base is coated with a strong pressure-sensitive adhesive or epoxy layer that bonds firmly to smooth materials such as metal, glass, composites, or painted panels. Once applied, the nut serves as a fixed anchor for bolts, screws, or threaded rods.

Adhesive mount nuts are often used in aerospace, automotive, marine, and electronics enclosures, where drilling could weaken the structure, create leaks, or expose internal components. They are valued for providing a clean, tool-free installation, reducing vibration transmission, and maintaining the integrity of thin or fragile surfaces.

Aerotight® Nut

An Aerotight® nut is a type of all-metal self-locking nut designed to resist loosening under vibration and dynamic loads. Unlike nylon-insert locknuts, Aerotight® nuts achieve their locking action by using an all-metal slotted collar at the top of the nut. When tightened onto a bolt, the collar flexes slightly, creating a continuous clamping force and friction on the threads that prevents the nut from backing off.

Because the locking feature is entirely metallic, Aerotight® nuts are heat-resistant, reusable, and reliable in harsh environments where nylon inserts or chemical locking methods might fail. They are often used in aerospace, rail, automotive, defense, and heavy machinery, where safety and vibration resistance are critical.

Alignment Pin

An alignment pin is a precision component used to accurately position and align two or more parts during assembly, machining, or installation. Unlike fasteners meant to bear structural loads like bolts or screws, the primary function of an alignment pin is for positioning and repeatability.

The key purpose of an alignment pin is to ensure accurate positioning, making sure that mating parts—such as plates, fixtures, or machine components—are assembled in the exact same location every time. This provides a consistent reference point and prevents misalignment or part shifting before final fastening.

There are several common types of alignment pins, each suited for different needs. Dowel pins are hardened, cylindrical pins that are often pressed into one part to align another. Taper pins have a slight taper, which allows for a snug fit while also making them easy to remove. Diamond pins have a unique cross-section that provides precise alignment while also accommodating for minor variations in hole tolerances. Finally, shoulder or locating pins have a stepped design, where the shoulder acts as a locator and the body fits into the hole.

Alignment pins are used in a wide range of industries, including tooling, mechanical assemblies, aerospace, and electronics. They are critical in applications like machining jigs and molds, aligning gears and shafts in mechanical assemblies, and ensuring precise tolerances in aerospace and automotive components. The key advantage of these pins is that they work alongside structural fasteners, preventing issues like stress, uneven loading, and premature wear that can occur when misaligned parts are forced into place.

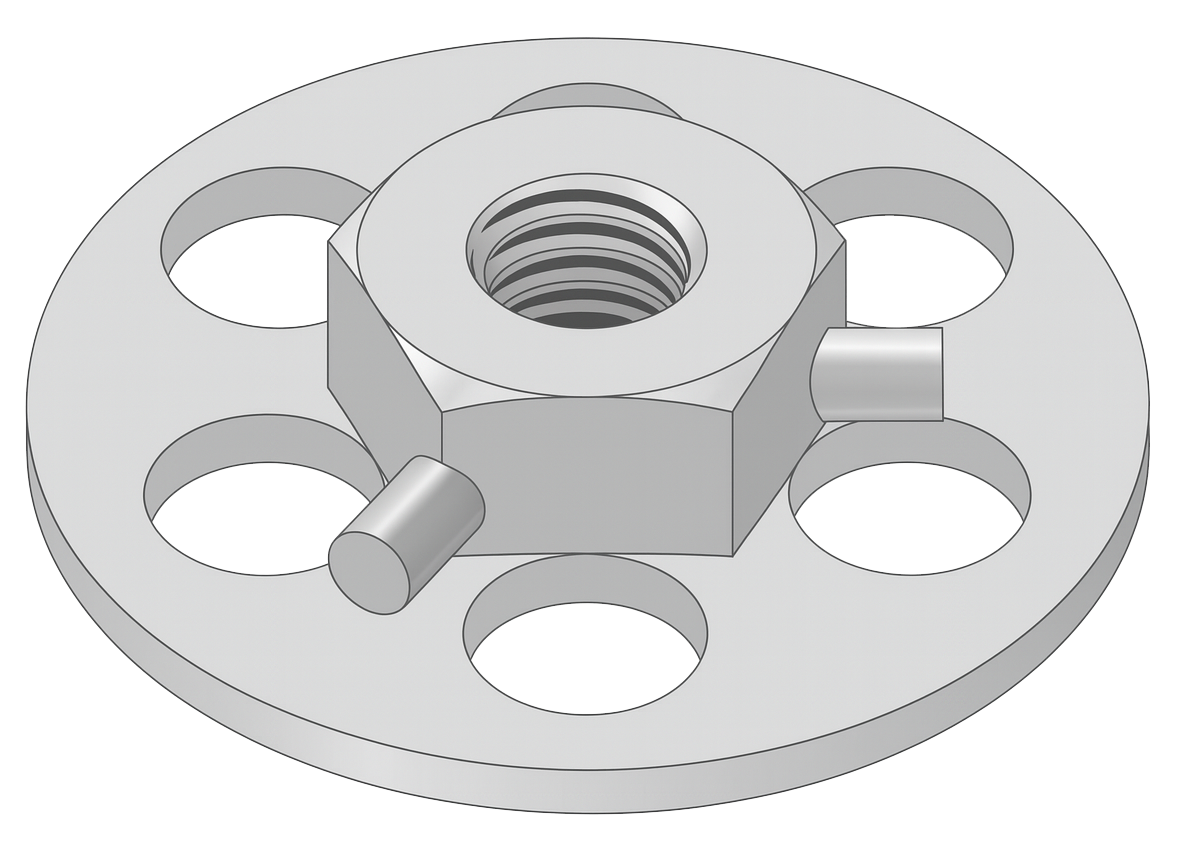

All Metal Hex Flange Lock Nut

The Hex Flange Lock Nuts, or Stover Flange Nuts, are crimped like Hex Top Lock Nuts and designed with a built-in washer. The crimped tops provide metal-to-metal gripping strength with male threads to prevent loosening. The washers give the nuts a wider clamping force — protecting the material being fastened. This nut excels in the vibrating world of truck frames. Earnest offers Hex Flange Lock Nuts in a Grade G strength equaling the strength level of Grade 8 nuts.

All Metal Hex Flange Lock Nut DIN 6927

An All-Metal Hex Flange Lock Nut DIN 6927 is a metal lock nut with an integrated flange that conforms to DIN 6927, a German standard. It is designed to resist loosening under vibration and torque without the use of nylon inserts or adhesives.

All Metal Lock Nut

Crowned Top Lock Nut, Stover Lock Nut, Prevailing Torque Lock Nut, Top Lock Locking Nut, and Auto Style Lock Nut all describe the Top Lock Nut, This common metal lock nut is crimped or slightly indented at the top to increase its grip strength. The Crimping creates metal-to-metal contact that prevents the nut from loosening in high-vibration applications.

All Metal Lock Nut DIN 980

An All-Metal Lock Nut DIN 980 is a metal self-locking hex nut that conforms to the DIN 980 standard, which specifies dimensions and performance for prevailing torque-type lock nuts. These nuts are designed to resist loosening under vibration and dynamic loads without using nylon inserts or adhesives.

Alloy Steel

Alloy steel is a type of steel that has been intentionally mixed with one or more alloying elements—such as chromium, nickel, molybdenum, vanadium, manganese, or tungsten—to improve its mechanical and physical properties beyond those of plain carbon steel. These added elements enhance characteristics like strength, hardness, toughness, wear resistance, and corrosion resistance, depending on the specific combination and percentage used.

At its core, all steel is primarily iron (Fe) with a small amount of carbon (C)—usually less than 2%. In carbon steel, carbon is the main hardening element, but in alloy steels, other elements are added (typically between 1% and 5%, though sometimes higher) to achieve specialized performance.

Different alloying elements serve specific purposes:

- Chromium (Cr): Improves hardness, corrosion resistance, and wear resistance.

- Nickel (Ni): Increases toughness and impact resistance.

- Molybdenum (Mo): Enhances strength at high temperatures and resists softening.

- Vanadium (V): Refines grain structure and increases toughness and fatigue strength.

- Manganese (Mn): Boosts strength and hardness while aiding deoxidation.

- Tungsten (W): Increases hot hardness and high-temperature strength.

Alloy steels are broadly classified into two groups:

- Low-alloy steels, with total alloying content below about 5%, used for general engineering and structural applications.

- High-alloy steels, with more than 5% total alloying elements, designed for highly specialized uses such as tool steels, heat-resistant steels, and stainless steels.

Common uses of alloy steels include gears, axles, crankshafts, fasteners, tools, high-strength structural components, and pressure vessels. Their ability to combine strength, toughness, and resistance to fatigue and corrosion makes them essential in automotive, aerospace, oil and gas, and heavy machinery industries.

Almen Strip

An Almen strip is a small, standardized piece of spring steel used to measure the intensity of shot peening. Shot peening is a surface treatment process that strengthens metal parts by bombarding them with small spherical media like steel shot, glass beads, or ceramic particles. This process introduces beneficial compressive stresses on the surface of the metal, which improves its resistance to fatigue and cracking.

The Almen strip provides a reliable way to measure and control peening intensity, as the intensity can vary depending on factors such as media size, velocity, angle, and time. When an Almen strip is mounted on a rigid block and exposed to the same peening process as the part being treated, its surface compresses and causes the strip to bend or arc upward. The amount of arc is measured with an Almen gauge, and this curvature serves as a direct indicator of the peening intensity.

There are three standardized types of Almen strips, each designed for a different range of peening intensity: Type A, the most common, is for general-purpose peening; Type N is thinner and used for lower intensity applications; and Type C is thicker and used for higher intensity peening.

The use of Almen strips is crucial in industries such as aerospace, automotive, and heavy manufacturing. They are used to treat parts like gears, springs, crankshafts, and aircraft components to extend their service life. By using Almen strips, manufacturers can ensure the shot peening process is both repeatable and verifiable, which is essential for meeting strict quality and safety standards.

Aluminizing

Aluminizing is a surface-treatment process that applies aluminum to a base metal (most often steel) to create a protective aluminum-rich layer that improves oxidation resistance, corrosion resistance, and heat resistance. Depending on the method, aluminizing produces either a diffusion-bonded aluminide layer (aluminum diffused into the substrate) or an aluminum/Al-Si metallic coating on the surface.

In industrial fastener and bolting applications, aluminizing is typically selected for components exposed to elevated temperatures (and often oxidizing or corrosive atmospheres) because aluminum-rich surfaces form a stable, protective aluminum oxide (Al₂O₃) film during service, helping the part resist scaling and degradation at heat.

Common aluminizing methods include hot-dip aluminizing, where the part is dipped in molten aluminum (often aluminum–silicon alloy) to form a coating, and pack cementation / CVD-type diffusion aluminizing (often called calorizing in older usage), where aluminum is diffused into the surface at temperature to form an aluminide diffusion layer that is metallurgically bonded and less prone to peeling or flaking.

Because aluminizing is a coating/diffusion treatment, it can affect thread fit and assembly behavior (coating buildup or diffusion-layer characteristics), and the chosen method is typically driven by the required temperature capability, corrosion environment, and dimensional tolerance needs. Also note the terminology: “zinc/aluminum flake coatings” used for corrosion protection on fasteners (zinc flakes sometimes with aluminum flakes in a binder) are a different coating family and are not what most specs mean by “aluminizing.”

Aluminum (Al)

Aluminum (chemical symbol Al, atomic number 13) is a lightweight, silvery-white metal known for its low density, strength-to-weight ratio, corrosion resistance, and high electrical and thermal conductivity. It is the most abundant metal in the Earth’s crust, making up about 8% of its mass, and is the second most widely used metal in the world, after steel.

In its pure form, aluminum is soft, ductile, and nonmagnetic, but it becomes much stronger when alloyed with other elements such as magnesium, silicon, copper, zinc, and manganese. These alloys are used extensively across industries because they combine lightness with strength and durability.

One of aluminum’s most important properties is its natural corrosion resistance. When exposed to air, it forms a thin, protective layer of aluminum oxide (Al₂O₃) on its surface that prevents further oxidation. This makes it ideal for applications in aerospace, automotive, construction, and marine environments.

Because it is both lightweight and strong, aluminum is used in aircraft and spacecraft structures, vehicle frames, bridges, and building facades. It’s also highly conductive, making it a common material for power lines, electronics, and heat exchangers. Additionally, it’s non-toxic and impermeable, which makes it perfect for food packaging, beverage cans, and kitchen utensils.

Aluminum is extracted primarily from bauxite ore, which is refined into alumina (aluminum oxide) and then reduced to metallic aluminum using the Hall–Héroult electrolytic process. This process is energy-intensive, which is why aluminum recycling is so valuable—recycling aluminum requires only about 5% of the energy needed to produce new metal.

Aluminum Bronze Fasteners

An Aluminum Bronze Fastener is a bolt, screw, nut, or other fastening component made from aluminum bronze, which is a copper-based alloy containing 5–12% aluminum and sometimes additional elements such as iron, nickel, or manganese. This alloy is highly valued for its combination of high strength, excellent corrosion resistance, and long-term durability, particularly in environments where other materials would fail. These properties make aluminum bronze fasteners a preferred choice in demanding and specialized industrial applications.

The properties of aluminum bronze fasteners are extensive. Their strength is comparable to, and in some cases greater than, many steels, yet they retain good ductility, which allows them to be used in applications requiring both toughness and flexibility. They also offer outstanding corrosion resistance, remaining unaffected by seawater, brine, sulfides, chlorides, and many industrial chemicals, which makes them especially well-suited for marine and offshore use. In addition, aluminum bronze has low-friction characteristics that provide excellent wear and galling resistance, reducing the chance of thread damage during installation or use. Another key property is that these fasteners are non-sparking, making them safe for use in explosive or flammable environments such as oil refineries, offshore rigs, and munitions facilities. Furthermore, because of their copper content, aluminum bronze fasteners also have antimicrobial qualities, helping resist bacteria and biofouling in wet or marine conditions.

These fasteners offer several advantages beyond their basic material properties. They deliver a long service life when used in saltwater and corrosive atmospheres, ensuring reliability in applications where replacement would be costly or impractical. They also retain their mechanical properties over a wide temperature range, performing effectively in both high and low heat environments. In addition, they combine strength with fatigue resistance, making them suitable for use in areas exposed to repeated stress and vibration. Their ability to withstand heavy loads while maintaining durability makes them ideal for critical installations.

The applications of aluminum bronze fasteners are broad and span multiple industries. In the marine industry, they are widely used in shipbuilding, propeller systems, pumps, and seawater valves. In oil and gas, they are applied in offshore drilling rigs, subsea equipment, and pipelines, where both corrosion resistance and non-sparking qualities are vital. In aerospace, they are chosen for areas requiring strength, fatigue resistance, and corrosion protection. In mining and heavy industry, these fasteners are used where abrasive and corrosive conditions are common, while in power generation, they are employed in turbines and equipment that operate in high-heat, high-humidity conditions.

Aluminum bronze fasteners are manufactured to meet strict standards to ensure consistency and performance. They are commonly produced in accordance with ASTM B150, ASME, or DIN specifications, which define alloy composition and mechanical requirements. Adjustments in aluminum and nickel content are made depending on the intended application, allowing manufacturers to tailor the alloy for specific mechanical strength or environmental resistance. This makes aluminum bronze fasteners a versatile and reliable option for some of the most challenging industrial environments.

Aluminum Fastener

An aluminum fastener is a fastening component—such as a bolt, screw, nut, rivet, or washer—made primarily from aluminum or aluminum alloys rather than traditional steels or other metals. These fasteners are chosen when a combination of light weight, corrosion resistance, and non-magnetic properties is required.

One of their most important features is that they are lightweight. Because aluminum has a much lower density than steel, aluminum fasteners are especially valuable in weight-sensitive industries like aerospace, automotive, and electronics. They also offer corrosion resistance, since aluminum naturally develops a thin oxide layer that shields it from atmospheric corrosion, particularly in non-saline environments. Additionally, they are non-magnetic, which is useful in applications where magnetic interference could disrupt electronic systems or other sensitive equipment. Another notable property is their conductivity, as aluminum is a good conductor of both electricity and heat, making certain fasteners suitable for electrical applications.

Aluminum fasteners see wide use across several industries. In aerospace and automotive applications, they help reduce weight, which improves performance and fuel efficiency. In electronics and electrical equipment, they are preferred for their non-magnetic nature and conductive qualities. In marine environments, they can be applied in boats, docks, and offshore structures, particularly when combined with protective coatings or specially designed alloys to resist saltwater damage. In architectural and construction projects, aluminum fasteners are ideal for lightweight assemblies, facades, and structures where corrosion resistance is critical.

Despite their advantages, aluminum fasteners have certain limitations. They generally have lower strength compared to steel, which means they cannot usually handle the same loads, though high-strength aluminum alloys such as 7075-T6 can enhance performance. They are also susceptible to thread galling, as aluminum threads are softer and can wear or strip if over-tightened. Finally, there is a galvanic corrosion risk when aluminum fasteners are used in contact with dissimilar metals like steel in moist or salty environments, unless protective insulation or coatings are applied.

Aluminum Oxide (Al₂O₃)

Aluminum oxide (chemical formula Al₂O₃) is a white, crystalline oxide of aluminum that occurs naturally as the mineral corundum. It is one of the most important industrial compounds, known for its exceptional hardness, high melting point, chemical stability, and electrical insulation properties.

In its pure crystalline form, aluminum oxide appears as colorless sapphire or red ruby, depending on trace impurities such as chromium or iron. Artificially produced aluminum oxide is typically a fine white powder, widely used in metallurgy, ceramics, abrasives, and electronics.

Aluminum oxide forms naturally when aluminum metal reacts with oxygen. This reaction creates a thin, adherent oxide film that protects aluminum from further corrosion or oxidation—this is why aluminum is so corrosion-resistant. The oxide layer is often thickened intentionally through anodizing, a process that enhances wear and corrosion resistance while allowing for decorative coloring.

In industrial applications, aluminum oxide is produced from bauxite ore through the Bayer process, which extracts and purifies the oxide as calcined alumina. This refined Al₂O₃ serves as the feedstock for aluminum metal production via the Hall–Héroult electrolytic process, where it is dissolved in molten cryolite and reduced to pure aluminum.

Aluminum oxide’s hardness (9 on the Mohs scale) makes it ideal for abrasives, such as sandpaper, grinding wheels, and cutting tools. It’s also an excellent thermal and electrical insulator, used in spark plugs, electronic substrates, resistors, and high-temperature crucibles. In ceramics and refractories, Al₂O₃ provides strength and heat resistance up to temperatures exceeding 2,000°C (3,632°F).

Additionally, aluminum oxide plays a role in chemical and medical fields—it’s used as a catalyst support, chromatography medium, and even as an ingredient in certain dental and orthopedic implants due to its biocompatibility and inertness.

AKA: Alumina

American Iron and Steel Institute (AISI)

The American Iron and Steel Institute (AISI) is a trade association that represents the North American steel industry. Established in 1908, it was created to promote the interests of steel producers, support research and development, and provide a unified voice on issues that affect the industry.

One of AISI’s key roles is industry representation, where it advocates on behalf of steelmakers in critical areas such as trade policy, environmental regulation, energy policy, infrastructure, and workforce development. It also plays a major part in standards development, having historically created and published technical standards and specifications for steel products, including structural steel design guides that are widely used by engineers and architects.

In addition, AISI invests heavily in research and innovation, funding and coordinating work in areas such as new steel grades, sustainability, recycling, advanced manufacturing, and energy efficiency. Beyond this, the organization is engaged in public outreach, promoting the benefits of steel—including its strength, recyclability, and sustainability—to governments, industries, and the public at large.

Anchor

Industrial anchors are heavy-duty fastening devices used to secure equipment, structures, or other items to concrete, steel, or other materials in industrial settings. These anchors are designed to handle significant loads and stresses, making them essential for various applications, including construction, manufacturing, and infrastructure projects.

Anchor Bolt

An anchor bolt is a type of fastener used to attach structural or non-structural elements to concrete. It typically consists of a long threaded bolt that is embedded into concrete—either cast in place while the concrete is poured or installed afterward using drilling and expansion or adhesive systems.

Anchor bolts provide a secure connection between concrete foundations and components like steel columns, light poles, machinery, or building frameworks. Depending on the design, they can be straight, L-shaped, J-shaped, or wedge-style, and may include washers and nuts for tightening.

Construction and civil engineering (securing columns, beams, and structural supports).

Industrial machinery (fixing heavy equipment to concrete bases).

Infrastructure (bridges, towers, light poles, and guardrails).

Anchor Eye Bolt

An anchor eye bolt is a type of fastener designed with a threaded shank on one end and a closed loop, or "eye," on the other, specifically intended for securing, lifting, or anchoring loads. Unlike standard eye bolts, which may simply be screwed into wood or metal, an anchor eye bolt is designed to provide stronger, more permanent anchoring, especially in masonry, concrete, or other heavy-duty applications.

The construction of an anchor eye bolt typically includes a forged steel or stainless steel body for strength and durability. The threaded portion is often paired with an expansion anchor, shield, or sleeve that grips into concrete or masonry when tightened. The closed eye creates a secure point for attaching ropes, cables, chains, or rigging hardware, making it versatile for load-bearing uses. Many are galvanized or coated to resist corrosion, especially in outdoor, marine, or industrial environments.

The main function of an anchor eye bolt is to provide a reliable anchor point. When properly installed, it distributes load evenly through its expansion mechanism, minimizing the risk of pullout. This makes it suitable for lifting operations, structural anchoring, and safety tie-downs. In construction, they’re often embedded into concrete floors or walls to serve as secure attachment points, while in marine applications they anchor rigging or mooring lines.

Common applications include construction and infrastructure, where they secure scaffolding, support beams, or lifting equipment; industrial machinery, where they serve as hoisting or tie-down points; and safety systems, such as fall arrest anchors or securing heavy loads. They’re also used in marine environments to anchor ropes and chains, benefiting from corrosion-resistant coatings.

The advantages of anchor eye bolts are their high load capacity, versatility, and ability to provide permanent, reliable anchoring in hard materials. They also resist pullout better than standard eye bolts when properly installed. However, limitations include the need for precise installation, as improper placement or insufficient embedment depth can compromise strength. They also generally require drilling into masonry or concrete, which adds complexity compared to simple screw-in eye bolts. Additionally, they are not always reusable, as the anchoring mechanism may deform during installation.

Angle Clamp

An angle clamp is a work-holding tool designed to securely grip two pieces of material at a fixed angle, most commonly 90 degrees. It ensures that the workpieces are held square and steady while they are being joined, welded, drilled, or otherwise worked on. Angle clamps are frequently used in woodworking, metalworking, and construction projects where precise corner joints are required.

The clamp usually has a right-angle frame with adjustable jaws that close onto the two workpieces. One jaw is typically fixed, while the other is movable and tightened using a threaded screw or quick-release mechanism. This setup allows the clamp to hold both pieces of material firmly in position while leaving the joint area accessible for fastening methods such as screws, nails, bolts, or welding.

Angle clamps provide several benefits. They allow for accurate alignment, ensuring that the joint is perfectly square and reducing errors in assembly. They also provide hands-free stability, so the user can focus on fastening or joining the materials without needing to manually hold them in place. Many designs also feature quick adjustments, enabling users to clamp and release materials efficiently, which is especially valuable in repetitive production or assembly work.

These clamps are commonly applied in cabinet making, furniture construction, picture framing, and metal fabrication. In woodworking, they help keep boards aligned while glue dries or while screws are driven into corner joints. In metalworking, they hold steel sections or tubing at right angles for welding, ensuring strong and precise joints.

In short, an angle clamp is an essential tool for achieving square, accurate joints by holding two pieces of material at a fixed angle, most often 90 degrees, during assembly or fabrication.

Angle of Twist

The angle of twist refers to the rotational displacement that a shaft or structural member undergoes when subjected to a torque or twisting moment. When one end of the shaft is fixed and the other end is loaded with torque, the shaft does not remain perfectly rigid. Instead, it twists about its longitudinal axis, and the total angular rotation between the two ends is known as the angle of twist. This value is typically expressed in radians or degrees and represents the elastic deformation caused by torsional loading.

The amount of twist is influenced by several key factors: the magnitude of the applied torque, the length of the shaft, the stiffness of the material, and the geometric properties of the cross-section. Mathematically, the angle of twist is expressed as θ = (T × L) / (G × J), where T is the torque, L is the shaft length, G is the shear modulus of the material, and J is the polar moment of inertia of the shaft’s cross-section. This equation shows that longer shafts and higher torques increase the twist, while stronger materials and larger cross-sectional resistance decrease it.

In engineering applications, controlling the angle of twist is important because excessive torsional deformation can lead to misalignment, vibrations, or even failure of mechanical systems. For example, in drive shafts, bolts, or structural members, engineers must ensure that the angle of twist stays within safe limits to maintain performance and reliability. Thus, the concept of angle of twist is critical in the design and analysis of rotating machinery, fasteners, and load-bearing components.

Annealing

Annealing is a heat treatment process used to soften metal, relieve internal stresses, improve ductility, and refine grain structure—essentially restoring a metal’s workability and toughness after it has been hardened or deformed through processes like forging, machining, or cold working.

The annealing process involves three main stages: recovery, recrystallization, and grain growth. The metal (often steel, copper, aluminum, or brass) is first heated to a specific temperature—high enough to allow atomic diffusion and structural changes, but below its melting point. For steel, this is typically between 550°C and 750°C (1020–1380°F), depending on composition. The metal is then held (soaked) at that temperature long enough for its internal structure to homogenize, allowing new strain-free grains to form. Finally, the material is slowly cooled, usually in the furnace, to prevent new stresses or hard microstructures from developing.

In carbon and alloy steels, the goal of annealing is to transform the microstructure (often distorted ferrite and pearlite from prior processing) into a softer, more uniform arrangement. This process eliminates dislocations and internal stresses created during cold working or welding, restoring ductility and machinability. In non-ferrous metals like copper or aluminum, annealing serves a similar purpose—removing work hardening effects and returning the metal to a more pliable state for further forming or shaping.

There are several types of annealing, each tailored to specific materials and goals:

- Full annealing: Heats steel above its critical temperature (austenitizing range) and cools it slowly to produce coarse pearlite—a very soft structure ideal for machining.

- Process annealing: Uses lower temperatures to relieve stress and restore ductility without changing the metal’s core structure—often used between cold working stages.

- Spheroidizing anneal: Applied to high-carbon steels to form rounded carbides, improving machinability before hardening.

- Stress-relief annealing: Removes residual stresses after welding, casting, or machining without significantly altering strength or hardness.

The cooling rate is critical: slow cooling in the furnace allows equilibrium microstructures to form, while rapid cooling may produce harder or more brittle phases (as in quenching).

Anodized Fasteners

An Anodized Fastener is a screw, bolt, nut, washer, or other fastening component that has been treated through the anodizing process, which is most commonly applied to aluminum but can also be used on titanium, magnesium, and other metals. Anodizing is an electrochemical treatment that thickens and strengthens the natural oxide layer on the surface of the fastener. This not only enhances durability and corrosion resistance but also provides opportunities for aesthetic improvements. Unlike coatings or paints, anodizing is not an external layer but an integral part of the metal’s surface, meaning it will not peel, chip, or flake off.

The anodizing process works by submerging the fasteners in an electrolytic acid bath and applying an electrical current. During this process, oxygen ions from the electrolyte bond with the surface of the metal, forming a controlled oxide layer. This layer is uniform, extremely durable, and porous enough to absorb dyes if desired. The result is a finish that can be both functional and decorative, offering improved performance while retaining the original lightweight properties of the base metal.

Anodized fasteners possess several valuable properties. The oxide layer significantly improves corrosion resistance, protecting against oxidation, moisture, and exposure to chemicals. The surface also gains increased hardness, making it more wear-resistant compared to untreated aluminum. The porous structure of the oxide film allows fasteners to be dyed in various colors, such as black, blue, red, or gold, which is useful for identification, aesthetic purposes, or color-coding in assembly processes. Additionally, anodizing creates electrical insulation, making the surface non-conductive, which is advantageous in electronic and aerospace applications. Importantly, anodized fasteners maintain the lightweight strength of aluminum, combining reduced weight with enhanced durability.

These properties translate into several advantages. Anodized fasteners exhibit excellent longevity in outdoor and marine environments, where untreated metals would corrode rapidly. They can be used for color-coding in manufacturing or for purely decorative purposes in industries such as automotive or construction. The finish produces a non-reflective matte appearance that reduces glare, and the surface is resistant to scratching and minor abrasion. Furthermore, the anodizing process is environmentally friendly, as it does not use heavy metals and produces very little waste compared to other finishing techniques.

Because of these qualities, anodized fasteners are widely applied across many industries. In the aerospace and aviation sectors, they are used for lightweight yet durable fastening solutions in structures, panels, and interiors. In electronics, anodized fasteners are chosen where insulation and corrosion resistance are required. In automotive and racing industries, they are popular both for reducing weight and for their cosmetic appeal, with brightly colored anodized bolts frequently found in engine bays, chassis, and performance components. The marine industry relies on anodized fasteners for their resistance to saltwater corrosion, while architecture and construction use them both for aesthetic facades and structural durability.

Anodized fasteners are produced in accordance with international and military standards to ensure consistency and performance. Standards such as MIL-A-8625 (U.S. military anodizing specification) and ISO 7599 govern the process and classification of anodized finishes. There are also distinct types of anodizing: Type I (Chromic Acid Anodizing) creates a thin oxide layer and is often used in aerospace for minimal dimensional change; Type II (Sulfuric Acid Anodizing) is the most common, general-purpose method and allows coloring; and Type III (Hardcoat Anodizing) produces a thicker, denser layer, resulting in extremely durable, wear-resistant surfaces ideal for demanding applications.

In summary, anodized fasteners combine lightweight strength with enhanced corrosion resistance, wear protection, and decorative versatility. They are integral to industries that require both functional performance and aesthetic options, making them a preferred choice in applications ranging from aerospace engineering to high-performance automotive design.

ANSI (American National Standards Institute)

ANSI stands for the American National Standards Institute, a private, non-profit organization that oversees the development of voluntary consensus standards for products, services, processes, systems, and personnel in the United States. Its primary purpose is to coordinate, accredit, and unify standards developed by other organizations to ensure consistency and reliability across industries. ANSI also serves as the official U.S. representative to international standard-setting bodies, including the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC), helping align U.S. practices with global requirements. By promoting uniform standards, ANSI ensures that products and services are safe, reliable, and compatible.

One of ANSI’s most important contributions is its role in accreditation. While ANSI itself does not write standards, it accredits the procedures of standards-developing organizations (SDOs) to ensure they follow requirements for openness, balance, consensus, and due process. This creates a fair and transparent system for developing industry-wide standards. ANSI’s influence extends across many industries, including construction, manufacturing, energy, safety equipment, and information technology.

ANSI’s work has a significant impact on both domestic and global trade. It plays a key role in harmonizing U.S. standards with international ones, helping reduce trade barriers and ensuring American products can compete in worldwide markets. For example, consistent standards guarantee that a product designed in the U.S. meets compatibility and safety expectations overseas.

In the fastener industry, ANSI standards are especially important. They define specifications for bolt, screw, and nut sizes, materials, strength grades, and testing methods. These standards ensure that fasteners manufactured in different locations are interchangeable and reliable. For example, a bolt produced in one state will fit properly with a nut made in another, thanks to the consistency provided by ANSI standards.

Anti-Galling Coating

An anti-galling coating is a protective surface treatment applied to fasteners and other metal components to prevent a specific type of wear known as galling. Galling occurs when sliding or threaded metal surfaces, particularly those made from materials like stainless steel, titanium, or aluminum, experience high friction under pressure. This friction can cause the surfaces to seize and weld together at contact points, which then tear apart and lead to severe damage or the complete seizure of the fastener.

The primary purpose of these coatings is to reduce friction and prevent metal-to-metal adhesion, allowing fasteners to be easily tightened, loosened, or reused without the risk of seizing or thread damage. They achieve this through several mechanisms: forming a thin, low-friction lubrication layer, creating a barrier to prevent direct metal-to-metal contact, and in some cases, improving wear resistance and surface toughness.

A variety of materials are used for anti-galling coatings, each with its own properties. Common types include PTFE (Teflon®) and other fluoropolymer coatings known for their low friction, and dry film lubricants such as molybdenum disulfide or graphite. Other options include nickel or silver plating for added lubricity and corrosion resistance, zinc flake coatings that offer both anti-galling and corrosion protection, and hard, smooth finishes like nitride and DLC (Diamond-Like Carbon) coatings.

These coatings are used extensively on fasteners and threaded inserts, especially in assemblies involving stainless steel. They are critical in industries like aerospace and automotive, where seizing in joints could lead to failure, as well as in oil and gas for high-pressure connections, and in medical implants where titanium orthopedic screws could be compromised by galling. The main benefits of these coatings are that they extend the service life of fasteners, ensure a consistent torque-tension relationship, prevent costly part damage, and allow for the reusability of components.

Arbor Bolt

An arbor bolt is a specialized bolt used to secure a saw blade or cutting tool to the arbor (the rotating shaft) of a power tool such as a miter saw or circular saw. Unlike standard bolts, arbor bolts are often designed with a flange or washer permanently attached and sometimes use reverse (left-hand) threads so that the rotation of the blade keeps the bolt tight instead of loosening it.

The arbor bolt threads into the saw’s arbor shaft and clamps the blade firmly in place against the tool’s flange. The design makes it easy to remove and replace blades while ensuring they remain secure during high-speed operation.

Miter saws and table saws for holding circular saw blades.

Cutting tools and grinders that require secure blade attachment.

Applications where safety and reliability at high RPM are critical."

Arbor Nut

An arbor nut is a specialized nut used to secure a cutting or grinding tool (such as a saw blade, grinding wheel, or sanding disc) to the arbor of a machine. The arbor is the rotating shaft or spindle that holds the tool, and the arbor nut threads onto it to keep the tool firmly in place during operation.

Arbor nuts are typically designed with flanges, flat faces, or special profiles to provide even clamping force and prevent the tool from slipping. Some machines use left-hand threads on arbor nuts so that the rotation of the tool tightens the nut rather than loosening it.

Table saws, miter saws, and circular saws to secure blades.

Angle grinders and bench grinders to hold grinding wheels.

Milling and cutting machines where precision tool holding is critical.

Arc Welding Stud

An Arc Welding Stud is a special type of fastener designed to be permanently attached to a metal surface using the arc stud welding process. Unlike conventional bolts or screws, which require holes and threads, an arc welding stud is fused directly onto a base material through an electric arc. This creates a permanent and extremely strong connection without the need for drilling or tapping. Arc welding studs are widely used in industries such as construction, automotive, shipbuilding, and heavy manufacturing, where efficiency, strength, and reliability are essential.

These studs are typically headed fasteners, meaning they consist of a shaft and a flanged or domed head that serves as the load-bearing surface after welding. The end of the stud that comes into contact with the base metal is specially designed—often equipped with a flux or ignition tip that helps initiate and stabilize the welding arc. When current is applied, the tip and a portion of the base metal melt together, forming a molten pool. The stud is then quickly pressed into this pool, and as the weld cools, the stud becomes permanently fused to the surface.

The properties and advantages of arc welding studs are numerous. The resulting joint provides extremely high strength, often equaling or exceeding the strength of the stud itself. Because no holes or threads are required, the process saves time and also avoids weakening the base material. The welded bond is continuous and sealed, which helps resist loosening and prevents leaks. Arc welding studs can be applied to a variety of metals, including steel, stainless steel, and aluminum, provided the correct welding system is used. Another key benefit is the speed of installation—each weld takes only a fraction of a second, allowing for high-volume and cost-efficient production.

Arc welding studs are used across a wide range of applications. In the construction industry, they are commonly applied as shear connectors welded to steel beams to secure composite flooring systems or bridge decking. In shipbuilding and offshore industries, they are used to secure components to steel decks or hulls without penetrating the surface, which helps maintain structural integrity and watertightness. The automotive industry uses arc welding studs in vehicle body assemblies, exhaust systems, and heat shields. In power generation and heavy industry, they are frequently used to attach insulation pins, mounting brackets, and supports to boilers, pressure vessels, and turbines. They also serve important roles in electrical and mechanical systems, where they provide permanent attachment points for grounding studs, pipe supports, and cable brackets.

To ensure consistency and quality, arc welding studs are manufactured in different diameters, lengths, and head designs to match their intended application. They are produced to recognized standards such as AWS D1.1 (Structural Welding Code – Steel), DIN EN ISO 13918, and other industry-specific requirements. The most common variations include full base studs for general use, shear connector studs for construction, threaded studs for mechanical fastening, and insulation pins for securing thermal or acoustic insulation. Together, these variations make arc welding studs one of the most versatile and reliable fastener types for permanent structural and mechanical attachments.

Asperities

Asperities are the microscopic peaks and valleys that make up a surface’s real topography. Even a surface that looks “smooth” to the eye is a landscape of uneven high spots (summits) and low spots at the micrometer or nanometer scale. When two parts touch, they don’t mate over the whole apparent area—load is carried at a sparse population of these asperity summits.

In contact, asperities concentrate pressure to very high local levels. Some summits elastically flatten, others plastically deform, and clean metal-to-metal junctions can briefly micro-weld, then shear. This behavior governs real contact area, friction, wear, heat generation, and noise. In bolted joints it also causes embedment relaxation: as asperities crush under clamp load—under the nut face, washer, and in the thread flanks—preload drops slightly after tightening.

Industrial implications are wide. For fasteners, asperities drive torque-to-tension scatter through their effect on the friction coefficient at threads and bearing surfaces; they contribute to galling in stainless/aluminum where micro-junctions weld and tear; and they influence sealing because leak paths run through unflattened valleys until compressive load “closes” them. In electrical/mechanical interfaces they set contact resistance and thermal conductance, since current/heat flows only through the real (asperity) contact spots. Asperity ridges are also common fatigue-crack initiators and corrosion nucleation sites because peaks see the highest stress and often the least protective film.

Asperities are specified and checked via surface roughness parameters measured with stylus or optical profilometers. Common 2D metrics include Ra (average roughness), Rq (RMS), Rz (mean peak-to-valley height), and bearing-area/Abbott–Firestone curve descriptors like Rpk/Rk/Rvk (peak/core/valley). For full-field control, 3D areal measures (Sa, Sq, Sz, Ssk, Sku) describe the surface over an area instead of a single trace.

You control asperities by changing topography, coatings, and lubrication. Finishing processes (grinding, honing, lapping, superfinishing, electropolishing, bead/shot blasting) tune peak height and valley volume. Platings and coatings (e.g., zinc, phosphate + oil, MoS₂, PTFE, DLC) modify asperity shape and chemistry, stabilizing friction and mitigating galling. Lubricants fill valleys and prevent metal-to-metal junctions. In bolted joints, hardened washers, proper surface finishes under the head/nut, and tightening practices that account for embedment (e.g., snug-pause-final) reduce preload loss and improve consistency.

ASTM (American Society for Testing and Materials)

ASTM stands for the American Society for Testing and Materials, officially known today as ASTM International. It is one of the world’s largest and most influential standards organizations, responsible for developing and publishing technical standards for materials, products, systems, and services used across virtually every industry — from construction and manufacturing to aerospace, energy, and consumer goods.

Founded in 1898 by a group of engineers and scientists, ASTM originally focused on standardizing the steel materials used in railroad construction, to ensure consistent quality and safety. Over time, its scope expanded dramatically, and today it maintains over 12,000 active standards that are recognized and used worldwide.

ASTM standards are voluntary consensus documents, meaning they are created through open collaboration among experts from industry, academia, government, and consumers. Each standard is carefully reviewed and approved by committees specializing in specific areas, such as ASTM A (ferrous metals), ASTM B (nonferrous metals), ASTM D (plastics), or ASTM F (fasteners and hardware).

For example:

- ASTM A193 defines requirements for high-temperature bolts and studs.

- ASTM A36 specifies carbon structural steel for construction.

- ASTM F593 covers stainless steel bolts, hex cap screws, and studs.

These standards describe chemical compositions, mechanical properties, test methods, tolerances, and quality assurance procedures, ensuring that materials and components meet consistent, verifiable specifications no matter where they are produced.

While ASTM standards are technically voluntary, they are widely adopted by governments, regulatory agencies, and industry bodies around the world. Many national and international codes, including those from ISO (International Organization for Standardization) and ANSI (American National Standards Institute), reference or harmonize with ASTM standards.

ASTM A193

ASTM A193 is a standard specification developed by ASTM International that covers alloy and stainless steel bolting materials used for high-temperature or high-pressure service, and for special purpose applications.

ASTM A194

ASTM A194 is a standard specification by ASTM International that covers carbon, alloy, and stainless steel nuts used primarily in high-pressure and high-temperature service conditions, often paired with bolts or studs made to ASTM A193.

ASTM A307

ASTM A307 is a standard specification from ASTM International that covers carbon steel bolts and studs with specified minimum tensile strength, generally used for general-purpose fastening applications in low- or moderate-strength environments. Covers carbon steel bolts and studs up to 3 inches in diameter with tensile strength typically around 60,000 psi (415 MPa).

ASTM A325

ASTM A325 is a widely used standard specification for structural steel bolts intended for high-strength connections in structural steel applications, such as building construction and bridges. Typically from 1/2 inch to 1-1/2 inch diameter, but sizes can vary.

ASTM A354

ASTM A354 is a standard specification from ASTM International that covers quenched and tempered alloy steel bolts and studs with specified minimum tensile strengths, typically used in high-strength and high-temperature applications where toughness and wear resistance are required.

ASTM A449

ASTM A449 is a standard specification from ASTM International that covers quenched and tempered alloy steel bolts, studs, and threaded rods with specified minimum tensile strength for high-strength mechanical applications. Commonly available in diameters up to 4 inches or larger for studs and rods.

ASTM A490

ASTM A490 is a standard specification from ASTM International for high-strength structural bolts made from alloy steel, designed for heavy structural steel connections requiring greater strength than ASTM A325 bolts. Typically from 1/2 inch up to 1-1/2 inch diameter, similar to A325 sizes.

ASTM A563

ASTM A563 is a standard specification from ASTM International that covers carbon and alloy steel nuts used in conjunction with structural bolts, such as those specified by ASTM A325 and ASTM A490.

ASTM F593

ASTM F593 is a standard specification from ASTM International that covers stainless steel bolts, hex cap screws, and studs used for general-purpose fastening applications.

ASTM F594

ASTM F594 is a standard specification from ASTM International that covers stainless steel nuts designed to be used with stainless steel bolts, screws, and studs—commonly those specified under ASTM F593.

Austenite

Austenite is a solid solution of carbon in gamma iron (γ-Fe) and is one of the primary microstructural phases in steel. It has a face-centered cubic (FCC) crystal structure, which gives it a higher capacity to dissolve carbon—up to 2.14% at 1147°C—and makes it nonmagnetic. Austenite exists only at elevated temperatures in plain-carbon steel (above the A3 or A1 transformation temperatures), but with certain alloying elements like nickel, manganese, and nitrogen, it can be stabilized at room temperature.

Key Characteristics

- Crystal structure: FCC (face-centered cubic), providing high toughness and ductility.

- Carbon solubility: Much higher than in ferrite (0.02% at room temp), allowing easier heat treatment.

- Magnetic behavior: Austenite is nonmagnetic, unlike ferrite and martensite.

- Formation temperature: Exists at ~727–1495°C depending on steel chemistry.

Role in Heat Treatment

Austenite is crucial in steel heat treatment because it is the parent phase that transforms into other microstructures:

- Pearlite (ferrite + cementite) when cooled slowly.

- Bainite under moderate cooling rates.

- Martensite, the hardest phase, under rapid quenching.

These transformations allow engineers to tailor steel’s hardness, strength, and toughness by controlling cooling rate and alloy composition.

Stabilization in Stainless Steel

In austenitic stainless steels (like 304 or 316), elements such as nickel and nitrogen stabilize austenite so it remains the dominant phase at room temperature. This provides:

- Excellent corrosion resistance

- Very high ductility

- Good formability and toughness

- Nonmagnetic properties

Where Austenite Appears in Iron–Carbon Alloys

- Naturally forms when steel is heated into the Austenite region of the iron–carbon phase diagram.

- Present in welds, heat-affected zones, and hot-working conditions.

- Exists temporarily during eutectoid transformations, influencing steel’s final microstructure.

Austenitic Stainless Steel

Austenitic stainless steel is a category of stainless steel characterized by its face-centered cubic (FCC) crystal structure, known as the austenitic phase. This structure is stable at both high and low temperatures and gives the alloy its defining properties—excellent corrosion resistance, high ductility, good weldability, and nonmagnetic behavior (in most conditions). Austenitic stainless steels are the most widely used type of stainless steel, accounting for roughly two-thirds of all stainless steel production.

The primary alloying elements in austenitic stainless steel are chromium (Cr) and nickel (Ni), though manganese (Mn) and nitrogen (N) can also be added to enhance strength and stability. Chromium, typically at levels of 16–26%, provides a passive oxide layer that protects the surface from oxidation and corrosion, while nickel (usually 6–22%) stabilizes the austenitic structure and improves toughness and formability.

This class of stainless steel is notable for its excellent resistance to corrosion and oxidation, even in aggressive environments such as marine, chemical, and food processing applications. It also maintains its strength and toughness at both cryogenic and elevated temperatures, making it suitable for a wide range of industrial uses—from fasteners, pressure vessels, and heat exchangers to kitchen equipment, architectural panels, and piping systems.

Austenitic stainless steels are grouped into several grades, with the most common being Type 304 (18% chromium, 8% nickel) and Type 316 (which adds about 2% molybdenum for improved resistance to chlorides and acids). While these steels are generally nonmagnetic, cold working can induce slight magnetism due to strain-induced transformation of some austenite into martensite.

Auto-Lubricated Fastener

An auto-lubricated fastener is a specially engineered bolt, screw, nut, or other fastening component that incorporates a built-in lubrication system or coating. This design removes the need for external lubrication during installation or service. These fasteners are created to reduce friction, prevent galling, and improve overall performance in applications where achieving consistent torque, maintaining preload, and ensuring long-term durability are essential.

Auto-lubricated fasteners can function in several different ways. Some use permanent coatings, such as dry-film lubricants made of molybdenum disulfide (MoS₂), graphite, or PTFE (Teflon®), which reduce friction on threads and bearing surfaces during tightening and loosening. Others use impregnated materials, where the fastener itself is manufactured from or lined with materials that slowly release lubrication over time. Another method involves encapsulated lubricants, in which microcapsules containing lubricating agents are embedded in the fastener surface and break open under stress or friction, delivering lubrication exactly where it is needed.

These fasteners provide several key benefits. They reduce friction, which ensures a more predictable torque-tension relationship and helps achieve proper clamp load with greater accuracy. They prevent galling, which is especially important for stainless steel fasteners that are prone to thread seizure if tightened without lubrication. They extend service life by maintaining lubrication that minimizes wear, corrosion, and fatigue across repeated use. They also support maintenance-free operation by eliminating the need for workers to manually apply lubricants, which improves reliability while reducing assembly time.

Auto-lubricated fasteners are widely used in industries where performance and reliability are critical. In aerospace and automotive, they provide secure fastening under high loads, vibrations, and varying temperatures. In oil, gas, and energy industries, they are used in pipelines, refineries, and turbines where re-lubrication is difficult or impossible. In marine environments, they protect against galling and corrosion for stainless steel fasteners exposed to saltwater. In electronics and precision equipment, they provide consistent fastening without the contamination risks that can come from traditional greases or oils.

Axial Load

An axial load is a force applied along the longitudinal axis of a structural member—such as a column, bolt, screw, or beam—either pulling it apart in tension or pushing it together in compression. The defining feature of an axial load is that it acts directly in line with the axis of the component, without introducing bending or twisting effects.

There are two main types of axial load. A tensile axial load is a pulling force that stretches or elongates the member along its axis, such as the tension present in a bolt that clamps two plates together. A compressive axial load is a pushing force that shortens or compresses the member, as seen in a vertical column carrying the weight of the structure above it.

When a member is subjected to an axial load, the stress is distributed uniformly across its cross-sectional area, assuming the load is perfectly centered. This axial stress is expressed as stress (σ) equals the applied load (P) divided by the cross-sectional area (A). If the load is not centered, a condition known as eccentric loading, bending stresses are introduced along with axial stress, which can decrease the stability and strength of the component.

Examples of axial loads are found in many engineering applications. Bolts and screws experience axial tension when tightened to hold components together. Columns and struts carry axial compressive loads from the weight of structural systems they support. Tie rods resist axial tensile loads to maintain the position of structural elements. Anchors may experience either tensile or compressive axial loads depending on how they are used.

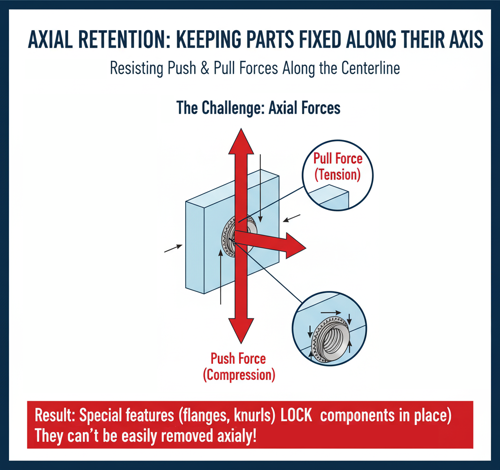

Axial Retention

Axial retention is the ability of a part—such as a fastener, bearing, or insert—to resist forces that try to push or pull it along its central axis. In other words, it measures how well the component stays fixed in place in the direction of its length, even when subjected to tensile (pulling) or compressive (pushing) loads.

To understand it simply: imagine trying to pull a pressed-in nut, stud, or bearing straight out of the material it’s installed in. The force required to do that represents its axial retention strength. A component with high axial retention will stay firmly in place, while one with poor retention may loosen, shift, or fall out under load or vibration.

In mechanical fastening, axial retention is critical for parts like self-clinching nuts, rivets, inserts, and bearings that are installed into thin sheet metal, castings, or plastic. These components typically rely on mechanical interlocking, friction, or adhesive bonding to achieve retention. For example, a self-clinching nut achieves axial retention when the surrounding sheet metal cold-flows into an undercut groove around the nut’s body during installation. This interlock physically prevents the nut from being pulled back out along its axis.

Axial retention is distinct from torque resistance, which refers to a fastener’s ability to resist rotation. The two often work together: torque resistance prevents spinning, while axial retention prevents pull-out. Engineers quantify axial retention using pull-out or push-out tests, where a controlled force is applied to determine the load at which the fastener or component dislodges.