Resources

Glossary

Jack Screw Actuator

A jack screw actuator is a mechanical device that converts rotary motion into linear motion using a threaded screw mechanism. It is essentially an advanced version of a jack screw, designed to lift, lower, push, or position heavy loads with precision. The actuator is driven by a motor (electric, hydraulic, or manual input), which rotates a worm gear or similar drive system. This rotation turns the lead screw inside the actuator, translating rotational motion into linear movement of the lifting shaft or nut.

In design and construction, jack screw actuators typically consist of a housing that encloses the worm gear system, a lifting screw (either translating or rotating), and bearings to support the movement. The lifting screw may either extend and retract to move the load directly or rotate a traveling nut that moves along the screw. They are built in different configurations, such as upright, inverted, translating, or rotating designs, depending on whether the load needs to be lifted from the top, supported from the bottom, or moved horizontally. Materials are usually high-strength steels or alloys, with surface treatments for wear and corrosion resistance.

The main function of a jack screw actuator is to handle large, controlled linear movements with minimal effort from the input side. They are capable of lifting or positioning loads ranging from a few hundred pounds to hundreds of tons, depending on the design. Many actuators are built to be self-locking, meaning they hold their position without continuous power, which is a key advantage in load-holding applications.

Common applications include industrial machinery, aerospace systems, and automotive assembly lines, where they are used for lifting platforms, adjusting machine positions, operating heavy doors or hatches, and handling loads in production processes. They are also widely used in stage and theater equipment to raise platforms, in renewable energy systems such as solar panel alignment, and in heavy construction equipment.

The advantages of jack screw actuators include their ability to provide precise, repeatable movement, their durability under heavy loads, and their versatility in both vertical and horizontal applications. They can also be linked together to move multiple actuators in synchronized motion. Limitations include slower operating speeds compared to hydraulic or pneumatic systems, the need for lubrication and maintenance, and efficiency losses due to friction in the screw threads.

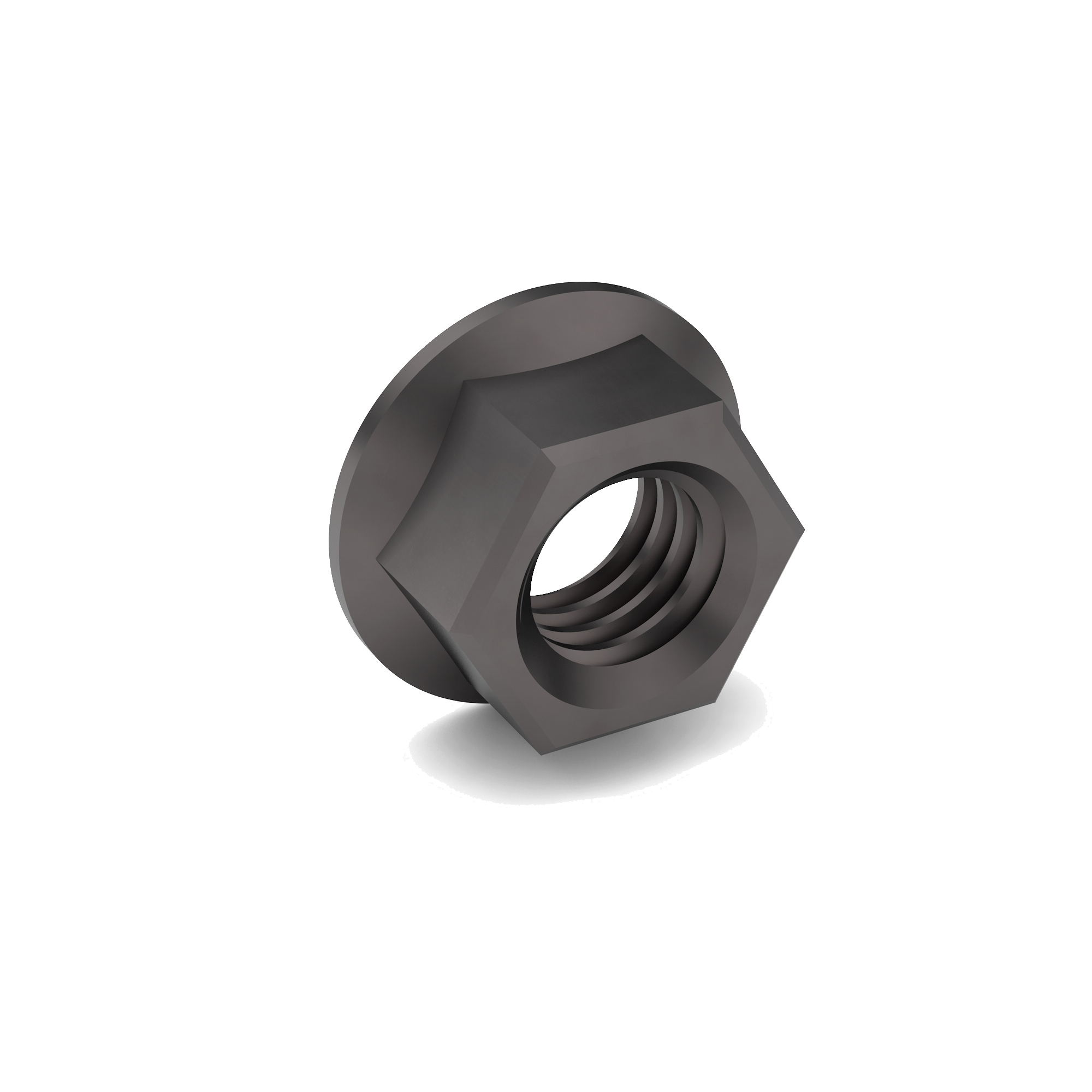

JIS Metric Hex Flange Nut

Hex Flange Nuts offer a unibody design that eliminates the need for a separate washer. The built-in flange distributes the clamping load over a wider area and reduces the risk of loosening due to vibration.

JIS Metric Hex Serrated Flange Lock Nut

Hex Serrated Flange Lock Nuts offer serrations on the bearing face of the flange that are designed to grip their installation surface to create locking resistance from loosening caused by vibration.