Resources

Glossary

#1 Elevator Bolt

A #1 elevator bolt, often referred to as a "#1 Norway elevator bolt." is a specific type of elevator bolt commonly used in the U.S. grain industry.

#3 Hd Plow Bolt

A #3 head plow bolt is a type of countersunk bolt with a square neck, designed to fit flush in heavy equipment cutting edges or plows, and the "#3" refers to the specific head style/size as defined in industry standards. If you're sourcing these bolts, the material grade and length are also important to specify.

#7 Hd Plow Bolt

A #7 head plow bolt is a heavy-duty, countersunk-head bolt with a square neck designed for high-stress applications. The "#7" refers to the head size and shape, not the thread size. It's commonly used in grader blades, snow plows, and other earth-moving equipment.

1/8" Extra Thick Fender Washer

An extra thick fender washer is a type of flat washer with a larger-than-standard outer diameter and increased thickness, providing additional strength and load distribution. Like standard fender washers, these are used to spread the load of a fastener (such as a bolt or screw) over a wider surface area, but the extra thickness makes them more suitable for heavy-duty applications where greater durability and support are required.

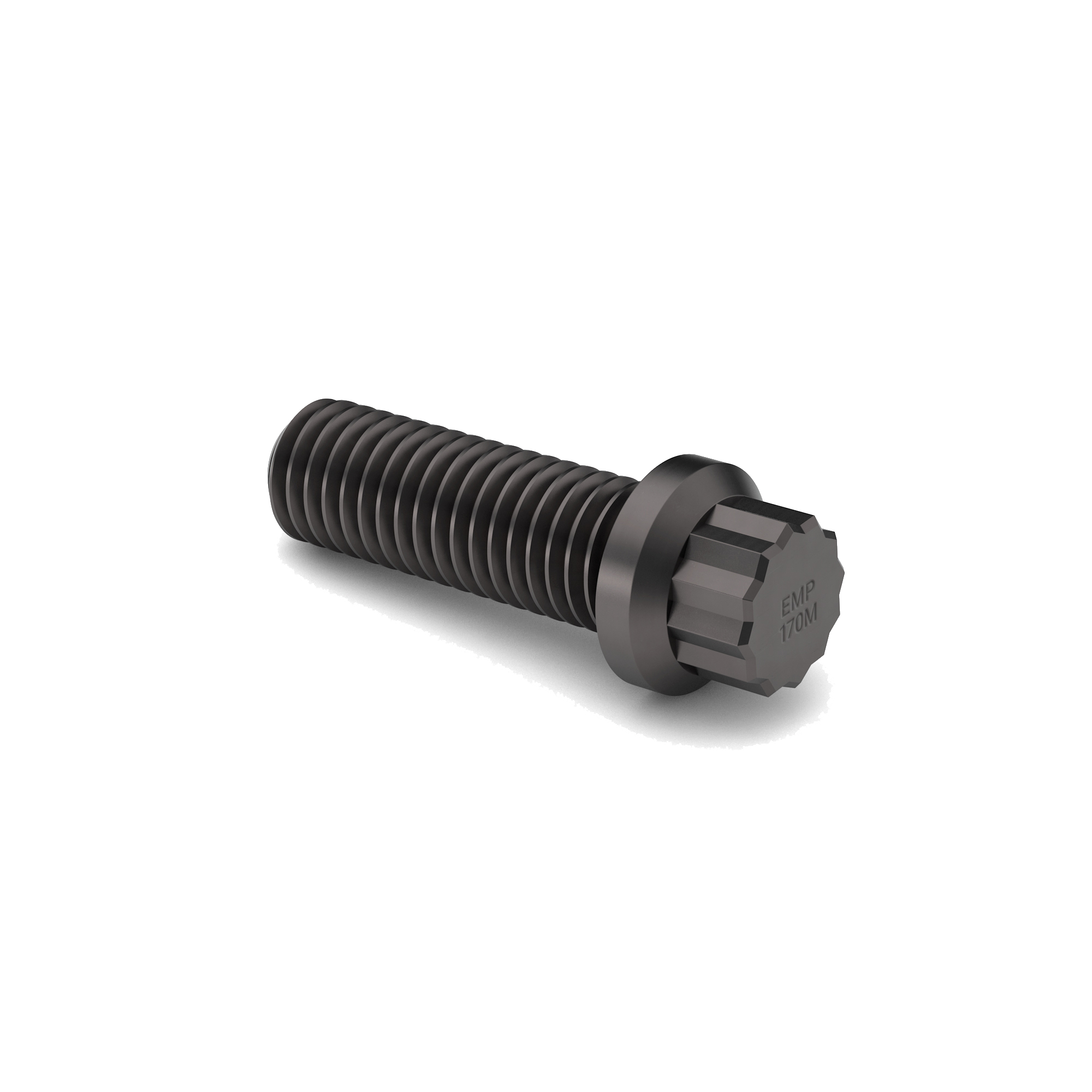

12 Point Flange Screw

A 12-point flange screw is a premium fastener combining a high-torque 12-point head with an integrated flange for load distribution. It’s ideal for critical applications where strength, vibration resistance, and torque access are essential.

12-Spline Drive

A 12-spline drive refers to a drive system that uses a tool interface with 12 splines (or ridges) inside the socket or wrench, designed to fit over a fastener with a matching 12-spline head. It works on the same principle as hex (6-point) or bi-hex (12-point) drives, but instead of using flat sides, the drive relies on spline-shaped engagement.

The 12-spline drive provides more points of contact between the tool and the fastener compared to a 6-point hex drive. This allows torque to be distributed across a larger surface area, reducing the chance of rounding off the fastener head and enabling the drive to handle higher loads. Another advantage is that it allows the tool to be positioned at smaller rotational increments, making it easier to work in confined or awkward spaces.

These drives are commonly used in aerospace, automotive, heavy equipment, and industrial applications where high-strength fasteners are involved. They are often paired with specialty bolts or nuts designed for high-stress environments, where traditional hex drives may not provide sufficient durability or torque transfer. The 12-spline drive is particularly valued in racing and aircraft applications, where both precision and strength are critical.

In simple terms, the 12-spline drive is the tool-side counterpart to 12-spline fasteners, designed to maximize grip, minimize wear, and provide flexibility in tight working conditions.

12-Spline Head

A 12-spline head refers to the design of a fastener head or tool interface that has 12 equally spaced splines (or ridges) around its circumference. Splines are similar to grooves or teeth cut into the head of the fastener, and they provide multiple points of contact for a matching tool, such as a 12-spline socket or wrench. This design creates a secure grip and allows torque to be applied evenly across the fastener.

The 12-spline head offers certain advantages compared to more common hexagonal (6-point) or double-hex (12-point) heads. With more engagement surfaces, it allows for higher torque transfer without rounding the fastener head. It also makes it easier to position the tool in tighter spaces, since the splines provide more entry points for the socket. This is especially useful in automotive, aerospace, heavy equipment, and industrial applications where accessibility can be limited.

In many cases, 12-spline heads are found on specialty bolts, nuts, or aerospace-grade fasteners where precision and strength are critical. They are often used in high-stress environments like aircraft engines, suspension components, or racing applications, where standard hex fasteners may not provide enough durability or torque-handling capacity.

12-UN Series

The 12-UN series refers to a group of Unified National (UN) screw threads that have 12 threads per inch (TPI), regardless of the nominal diameter of the fastener. It is part of the Unified Thread Standard (UTS), which is the primary thread system used in the United States, Canada, and other countries that follow inch-based standards.

Within the UTS system, thread designations are typically identified by three key factors: the diameter, which is the major diameter of the screw measured in inches; the series, which specifies the type of thread such as UNC (Unified National Coarse), UNF (Unified National Fine), UNEF (Unified National Extra Fine), or UN (Unified National Special); and the number of threads per inch (TPI).

The 12-UN series falls under the Unified National Special (UN) category because 12 TPI is not included in the standard coarse or fine pitch options for most diameters. Instead, it is considered a “constant pitch” thread series, which means that every fastener size in this series has exactly 12 threads per inch. This makes it unique compared to the more variable thread densities found in coarse or fine series.

This type of thread series is commonly used for larger-diameter fasteners, where the use of coarse or fine series would otherwise result in threads that are either too widely spaced or too tightly packed for practical strength and engagement. It also finds applications in aerospace, automotive, and industrial environments where non-standard thread combinations are needed. In addition, the 12-UN series provides a balance between the strength typically associated with coarse threads and the fine adjustment capabilities offered by finer threads.

For example, a 1"-12 UN thread describes a screw with a 1-inch major diameter and 12 threads per inch, while a 1 1/4"-12 UN thread describes a screw with a 1.25-inch major diameter and the same 12 threads per inch. This consistency across sizes makes the 12-UN series particularly useful in specialized fastening situations.

16-UN Series

The 16-UN series refers to a group of Unified National (UN) screw threads that have 16 threads per inch (TPI), regardless of the fastener’s nominal diameter. Like the 12-UN series, it is part of the Unified National Special (UN) category within the Unified Thread Standard (UTS), which is the inch-based thread system widely used in the United States, Canada, and other countries that follow imperial standards.

In the UTS system, threads are typically classified by three main features: the diameter (major diameter of the screw in inches), the series (UNC for coarse, UNF for fine, UNEF for extra fine, and UN for special), and the number of threads per inch. The 16-UN series is considered “special” because 16 TPI is not part of the standard coarse or fine pitch options across most diameters. Instead, it is a constant pitch series, which means that every size in the series, whether 1 inch, 1 1/4 inches, or larger, is cut with 16 threads per inch.

The 16-UN series is especially useful in applications where a consistent and relatively fine pitch is required across a range of diameters. This series provides stronger engagement than extra-fine threads while still allowing precise adjustment, making it popular in aerospace, automotive, military, and industrial applications where non-standard combinations are necessary. It is also chosen for larger-diameter fasteners where using coarse or fine threads might not provide the desired balance between holding strength, vibration resistance, and ease of assembly.

For example, a 1"-16 UN thread describes a fastener with a 1-inch major diameter and 16 threads per inch, while a 1 1/2"-16 UN thread describes a fastener with a 1.5-inch major diameter and the same 16 threads per inch. By maintaining the same pitch across multiple diameters, the 16-UN series simplifies certain design requirements and provides a specialized solution where standard UNC or UNF series are not sufficient.

18/8 Stainless Steel (Type 304)

18/8 stainless steel is a common grade of stainless steel that contains 18% chromium and 8% nickel in its composition. These two alloying elements are what give stainless steel its corrosion resistance and strength. Chromium forms a thin, invisible oxide layer on the surface that protects the metal from rust and staining, while nickel improves toughness, ductility, and resistance to acids and other corrosive environments.

This grade falls into the austenitic stainless steel family, which is known for its non-magnetic properties (in the annealed state), excellent formability, and high resistance to oxidation. It’s often identified by the designation Type 304 stainless steel, which is the most widely used stainless steel around the world.

18/8 stainless steel is valued for being durable, corrosion-resistant, and easy to clean, making it ideal for applications in food processing, kitchenware, fasteners, chemical equipment, medical instruments, and architectural uses. In fasteners, 18/8 stainless bolts, nuts, and washers are popular because they maintain their strength while resisting rust in outdoor or humid conditions.

AKA: Type 304

2-Way Lock Nut

Side Lock Nuts, or Center Lock Nuts, are common all-metal Hex Lock Nuts with side crimps. These side crimps are engaged when the nut is applied to a male thread. The crimping creates metal-to-metal contact that prevents the nut from loosening in high-vibration applications. Earnest offers Top Lock Nuts in Grades A and 8 to ensure their strength and durability.

AKA: Reversible Lock Nut, Center-Lock Nut

316 Stainless Steel

316 stainless steel is an austenitic grade of stainless steel known for its superior corrosion resistance compared to the more common 304 (18/8) stainless. Like other austenitic steels, it contains chromium and nickel, but what sets it apart is the addition of molybdenum (about 2–3%), which significantly improves its resistance to pitting, crevice corrosion, and attack from chlorides and saltwater environments.

The typical composition of 316 stainless steel is around 16–18% chromium, 10–14% nickel, 2–3% molybdenum, and the balance iron, with small amounts of manganese, silicon, and carbon. This combination makes it exceptionally durable in marine conditions, chemical processing environments, and medical applications.

Because of its toughness and resistance to harsh conditions, 316 stainless steel is often called “marine grade stainless steel.” It’s widely used in shipbuilding, coastal architectural structures, food and pharmaceutical processing equipment, surgical instruments, and high-strength fasteners that must withstand exposure to moisture, chemicals, or salt.

In fastener applications, 316 stainless steel bolts, nuts, and washers are preferred when maximum corrosion resistance is needed—such as in marine, chemical, or outdoor structural settings. While it is more expensive than 304 stainless, the added longevity and reliability in severe environments often justify the cost.

6g Tolerance Class

A 6g tolerance class is a designation in the ISO metric screw thread system that defines the allowable variation in size and fit for external threads, such as bolts, screws, and studs. It is governed by ISO 965, which establishes the rules for manufacturing and ensures that threaded parts remain interchangeable across industries and applications worldwide.

The tolerance class is expressed using a number and a letter. The number represents the grade of tolerance, which indicates the amount of permissible variation. Lower numbers mean a tighter tolerance and greater precision, while higher numbers mean looser tolerances with more clearance. The letter identifies whether the tolerance applies to internal or external threads. Uppercase letters, such as H, are used for internal threads like nuts, while lowercase letters, such as g, are used for external threads like bolts.

In the case of 6g, the number 6 represents a medium-grade tolerance that strikes a balance between manufacturability and performance. The letter g designates it as an external thread with a fundamental deviation that creates a small but reliable clearance when paired with the common internal tolerance class 6H. This ensures that a 6g bolt will properly mate with a 6H nut, creating a fit that is neither excessively tight nor too loose.

The 6g tolerance class is the most widely used standard for metric bolts and screws. It provides a dependable and practical fit for general-purpose fastening across mechanical engineering, automotive, aerospace, and construction industries. Its balance of ease of manufacture, strength, and interchangeability is why it has become the default choice for most external threaded fasteners.

6H Tolerance Class

A 6H tolerance class is part of the ISO metric screw thread system and specifies the tolerance for internal threads, such as those found in nuts, tapped holes, or other threaded components. It is defined under ISO 965, the international standard that governs how metric threads are manufactured to ensure that they fit together properly and remain interchangeable across industries.

The designation is made up of a number and a letter. The number indicates the tolerance grade, which reflects how tight or loose the limits are on the thread’s size. Lower numbers represent tighter, more precise tolerances, while higher numbers allow more clearance and looser fits. The letter shows whether the tolerance is for internal or external threads and the position of the fundamental deviation. For internal threads, uppercase letters like H are used, while lowercase letters, such as g, are used for external threads.

In the case of 6H, the number 6 represents a medium tolerance that is widely considered the standard balance between manufacturability and performance. The H indicates an internal thread with no fundamental deviation, meaning that the minimum material condition of the nut or tapped hole is at the basic size. This ensures that the thread is not undersized and that there will always be proper clearance for the mating external thread.

The 6H tolerance class is the most common choice for internal threads in general-purpose fasteners. When paired with an external thread of 6g tolerance class, it provides a reliable fit that is easy to assemble and disassemble, yet strong enough to perform in most engineering, automotive, aerospace, and construction applications. Its universality makes 6H the default standard for nuts and tapped holes across much of the fastener industry.

8-UN Series

The 8-UN series refers to a standardized thread series defined by the Unified Thread Standard (UTS). In this designation, the “8” represents eight threads per inch (TPI), and “UN” stands for Unified National, which is the system of thread forms used primarily in the United States, Canada, and other countries that follow inch-based standards. Unlike coarse (UNC) or fine (UNF) thread series, the UN series designations such as 8-UN, 12-UN, and 16-UN are classified as constant pitch thread series.

A constant pitch series means that all diameters in the series share the same pitch, regardless of the thread size. For example, in the 8-UN series, every thread—whether small or large in diameter—has 8 threads per inch. This uniformity simplifies design when multiple diameters need to engage with the same pitch for consistency or interchangeability.

The 8-UN series is typically used in larger diameters where standard UNC or UNF threads are impractical, and where maintaining strength, ease of manufacturing, and compatibility are important. It often appears in applications involving heavy equipment, structural assemblies, pressure vessels, and other critical industrial uses where reliable threading at large diameters is required.