Resources

Glossary

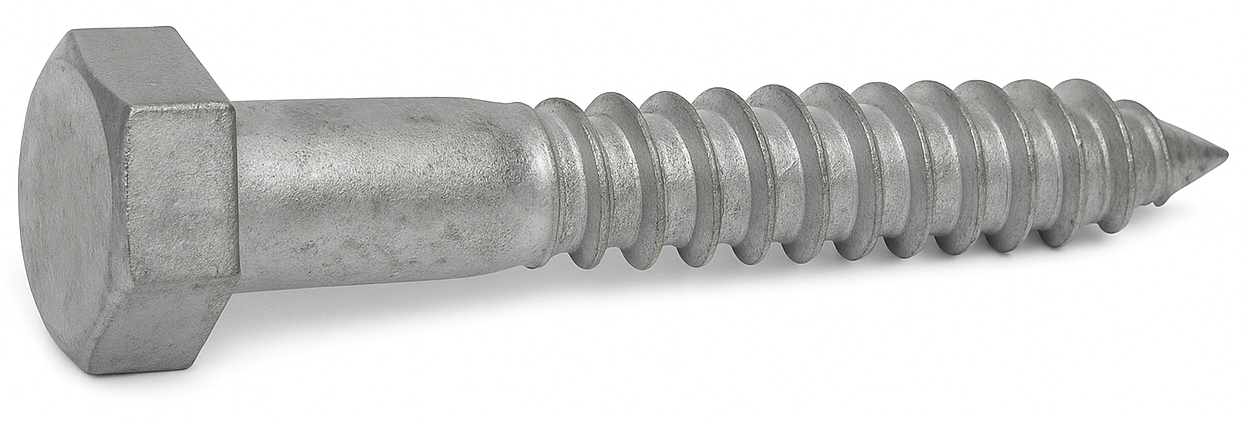

Lag Bolt

A lag bolt, also called a lag screw, is a large, heavy-duty fastener designed for securing materials that need a strong, durable hold. Unlike standard screws, lag bolts have hexagonal heads that require a wrench or socket for installation rather than a screwdriver. Their bodies feature deep, coarse threads that allow them to cut into wood and other softer materials, creating a very strong mechanical grip.

Lag bolts are typically made from steel and often feature protective coatings like zinc plating, hot-dip galvanizing, or stainless steel construction to resist corrosion. They come in a variety of lengths and diameters, making them suitable for both light-duty and heavy-duty applications.

The main purpose of a lag bolt is to provide a secure fastening in applications where nails, smaller screws, or other fasteners would not be strong enough. They are commonly used in construction for fastening lumber, attaching heavy timbers, securing wooden beams, and connecting wood to masonry or concrete (often with the use of anchors).

One of the key advantages of lag bolts is their exceptional load-bearing capacity, making them ideal for structural applications. They can handle shear and tension forces effectively, which is why they are used in building decks, wooden bridges, log homes, and utility pole connections. However, because they require pre-drilled pilot holes in most cases, installation can take longer than with standard screws. Additionally, once installed, lag bolts are not as easily removed or adjusted as lighter fasteners.

Lapping

Lapping is a precision finishing process used in manufacturing to achieve extremely flat, smooth, and accurate surfaces on a material. It involves rubbing two surfaces together with an abrasive slurry or compound between them. The abrasive particles—suspended in a liquid or paste—gradually cut away microscopic amounts of material, removing high spots and irregularities to create a fine, uniform finish.

In practice, lapping is often done with a hard tool or plate (commonly made of cast iron, copper, or glass) against the workpiece, with the abrasive medium applied in between. Unlike grinding or polishing, lapping removes material in a controlled, very slow manner, allowing for tolerances within millionths of an inch (microns) and surfaces with extremely low roughness values.

The process is commonly used in applications where exact fit, sealing, or optical clarity are essential. Examples include valve seats, gauges, bearing surfaces, optical lenses, and sealing faces in engines or pumps. Lapping ensures surfaces are not only flat but also free of burrs, waviness, or tool marks.

There are two main types: manual lapping, where parts are worked by hand against a lapping plate, and machine lapping, which uses powered lapping machines for higher precision and consistency. While lapping produces superior accuracy, it is relatively slow and usually reserved for finishing operations where conventional machining cannot meet the required tolerances.

Large Hex Serrated Flange Locking Machine Screw

A Large Hex Serrated Flange Locking Machine Screw is a type of fastener designed for heavy-duty applications where a secure, vibration-resistant connection is necessary. It combines a large hexagonal head with a serrated flange that provides a locking function without needing additional washers. This screw is commonly used in industrial and construction settings, where strong, reliable fastening is required.

Large Hex Serrated Flange Nut

A large hex serrated flange nut is a type of fastener that combines a hexagonal shape with an integrated flange at the base, along with serrations on the flange. This design enhances the nut's grip on the material and provides resistance to loosening due to vibration or movement, making it especially useful in heavy-duty applications.

Lashing Ring

A lashing ring, also known as a D-ring or tie-down anchor, is a metal ring designed to serve as a strong and reliable anchor point for securing cargo. These rings are crucial for preventing loads from shifting or moving during transport, which is essential for safety and preventing damage. Lashing rings are commonly made from durable materials like steel or stainless steel and are built to withstand heavy forces and environmental wear.

The design of lashing rings offers a versatile and easy-to-use attachment point for various cargo securing hardware. The "D" shape, with its straight back and open loop, makes it easy to attach straps, ropes, and chains. By using these anchors to tighten a load restraint, cargo can be firmly clamped down to the floor of a vehicle or container, providing stability during transit.

Several types of lashing rings are available, each suited for different applications. Weld-on rings offer maximum strength and a permanent anchor point, as they are welded directly to a metal surface. Bolt-on rings are installed with heavy-duty bolts, making them easy to install and reposition as needed. Recessed rings are mounted flush with the floor or wall of a trailer, creating a smooth surface that eliminates tripping hazards and prevents snagging. For irregularly shaped loads, pivotal or fold-over rings provide flexibility, as they can rotate or fold down when not in use.

Lashing rings are used across many industries, including transportation, logistics, and marine. They are found on trucks, trailers, flatbeds, and shipping containers to secure everything from heavy machinery and agricultural equipment to consumer goods. By using lashing rings, businesses ensure that cargo remains stable and secure, which minimizes financial losses from damaged goods and reduces the risk of accidents caused by shifting loads.

Lead (Pb)

Lead is a dense, soft, bluish-gray metal with the chemical symbol Pb (from the Latin plumbum) and an atomic number of 82. It is one of the heaviest and most malleable metals, known for its high density, corrosion resistance, and low melting point (327.5°C or 621.5°F). Lead has been used by humans for thousands of years — from ancient plumbing and pigments to modern batteries and radiation shielding — though its use has declined due to health and environmental concerns.

In its pure form, lead is easily shaped, stretched, or cast, making it extremely versatile for industrial use. It tarnishes slowly when exposed to air, forming a protective oxide coating that prevents deeper corrosion, similar to how zinc or aluminum behave. Unlike most metals, lead is non-sparking, highly resistant to acids, and an excellent sound and vibration dampener, which is why it’s been used historically in pipes, roofing, ammunition, and protective barriers.

The most common modern application for lead is in lead-acid batteries, which power vehicles and provide backup energy for uninterruptible power systems (UPS). In this form, lead is used both as lead dioxide (PbO₂) at the positive plate and spongy lead (Pb) at the negative plate, with sulfuric acid acting as the electrolyte. This chemistry makes lead indispensable in battery technology, particularly for starting engines and providing reliable, recyclable energy storage.

Lead is also used in radiation shielding because of its high density and ability to absorb X-rays and gamma rays. Hospitals, dental offices, and nuclear facilities use lead-lined walls, aprons, and containers for protection. Additionally, it finds use in weights, counterbalances, solder, and cable sheathing—applications that rely on its weight, flexibility, and low melting point.

However, lead is toxic to humans and animals. It accumulates in soft tissues and bones, interfering with the nervous system, kidneys, and reproductive health. Chronic exposure—especially from lead paint, contaminated water, or industrial emissions—can cause serious developmental and neurological damage. As a result, lead has been phased out from gasoline, paint, plumbing, and most consumer products in favor of safer alternatives.

Lead is primarily obtained from the mineral galena (lead sulfide, PbS), though it often occurs with other metals like zinc, silver, and copper. The metal is extracted through smelting and refining processes, after which it can be alloyed or purified for specific uses.

Lead Screw

A lead screw (also called a power screw or translation screw) is a mechanical device that converts rotational motion into precise linear motion. It consists of a threaded shaft and a mating nut that moves along the screw’s threads when the shaft rotates. This controlled linear movement allows lead screws to lift loads, position components, or apply force with high accuracy and repeatability.

Lead screws are widely used in machine tools, actuators, vises, CNC machines, 3D printers, and precision instruments, where smooth and consistent motion is required. The thread shape plays a key role in performance—most lead screws use Acme (trapezoidal) or square threads, which provide high efficiency, load capacity, and reduced backlash compared to standard V-threads.

One of the defining features of a lead screw is its lead, which is the linear distance the nut travels in one full revolution of the screw. The pitch and lead together determine how fast or slow the linear movement occurs.

Lead screws are often chosen over ball screws when self-locking is desired—that is, when the screw resists back-driving under load, allowing it to hold a position without external braking. However, they generally have lower mechanical efficiency compared to ball screws because of higher friction between the screw and nut.

Lead Thread

The initial, partially formed, or tapered threads at the very end of a screw or bolt. These are designed to help guide the fastener into a nut or tapped hole. Its primary purpose is to facilitate easy engagement and proper alignment, thereby reducing the likelihood of cross-threading during assembly.

Ledeburite

Ledeburite is a hard, brittle microstructural phase found in iron–carbon alloys, specifically cast irons, that forms when the alloy solidifies at the eutectic composition—about 4.3% carbon—at around 1147°C (2097°F). It is named after metallurgist Adolf Ledebur, who first described it.

Ledeburite is not a single substance but a eutectic mixture of two phases:

- Austenite (γ-iron)

- Cementite (Fe₃C), also known as iron carbide

When the alloy cools further, the austenite usually transforms into pearlite (a ferrite–cementite lamellar structure), leaving behind a final room-temperature microstructure that consists of pearlite + cementite. Because cementite is extremely hard and brittle, regions of ledeburite give cast iron very high hardness and abrasion resistance but also low ductility.

Key characteristics of ledeburite:

- Forms only during solidification at eutectic carbon levels in iron–carbon alloys.

- Appears as a white, feathery or network-like structure under a microscope.

- Indicates the material is in the category of white cast iron, which fractures with a white, crystalline surface due to the presence of cementite instead of graphite.

- Contributes to excellent wear and erosion resistance, making white irons useful for grinding media, slurry pumps, liners, and abrasion-intensive applications.

Left-Handed Threads

Threads that tighten when turned counterclockwise (to the left). These are less common than right-handed threads and are used in applications where rotation or motion could cause a right-handed thread to loosen.

Length

The measurement of a fastener from the bottom of the head to the end of the threaded or unthreaded shank.

Lifting Socket

A lifting socket is a high-strength, internally threaded insert that is cast into (or otherwise permanently installed in) a component to provide a rated lifting/hoisting attachment point. In fastener terms, it functions like a heavy-duty female-thread anchor that accepts a compatible lifting eye/eyebolt, lifting loop, hoist ring, or lifting clutch adapter, allowing the part to be lifted, handled, or positioned safely during manufacturing, shipping, and installation.

Key identifying features

- Internal threads sized to match the designated lifting hardware.

- Common in threaded socket lifting systems for precast, where the socket is designed for lifting and transport of concrete elements.

- Many designs include a lateral cross-hole below the threaded section to accept a reinforcing bar that ties into the rebar cage for anchorage in concrete.

- Often supplied with thread protection plugs to keep concrete/debris out during casting and handling.

Common applications

- Precast concrete handling (lifting, turning, transporting, erecting panels/slabs/beams).

- Heavy assemblies where a clean, reusable threaded lift point is preferred over slings wrapped around the load.

Important note (safety-critical)

Lifting sockets are engineered lifting points and must be used with the correct matching lifting hardware and rated working load limits (WLL) per the manufacturer/system documentation.

AKA: Threaded Lifting Socket, Cast-in Lifting Socket, Flat Plate Lifting Socket

Linear Actuator

A linear actuator is a mechanical device that converts rotational motion into linear motion, allowing it to move or position objects in a straight line rather than in a circular path. Unlike motors that spin, linear actuators extend and retract — pushing, pulling, lifting, or adjusting loads with controlled precision.

They are used in a wide range of industrial, commercial, and consumer applications, such as automation equipment, robotics, machine tools, medical devices, valves, adjustable desks, and vehicle systems.

Linear actuators can be powered by different energy sources:

- Electric actuators use a motor and a lead screw (or ball screw) mechanism to drive movement.

- Hydraulic actuators use pressurized fluid to generate force and motion.

- Pneumatic actuators rely on compressed air to create movement.

The electric linear actuator is the most common in modern automation because it offers precise control, quiet operation, and easy integration with sensors and control systems.

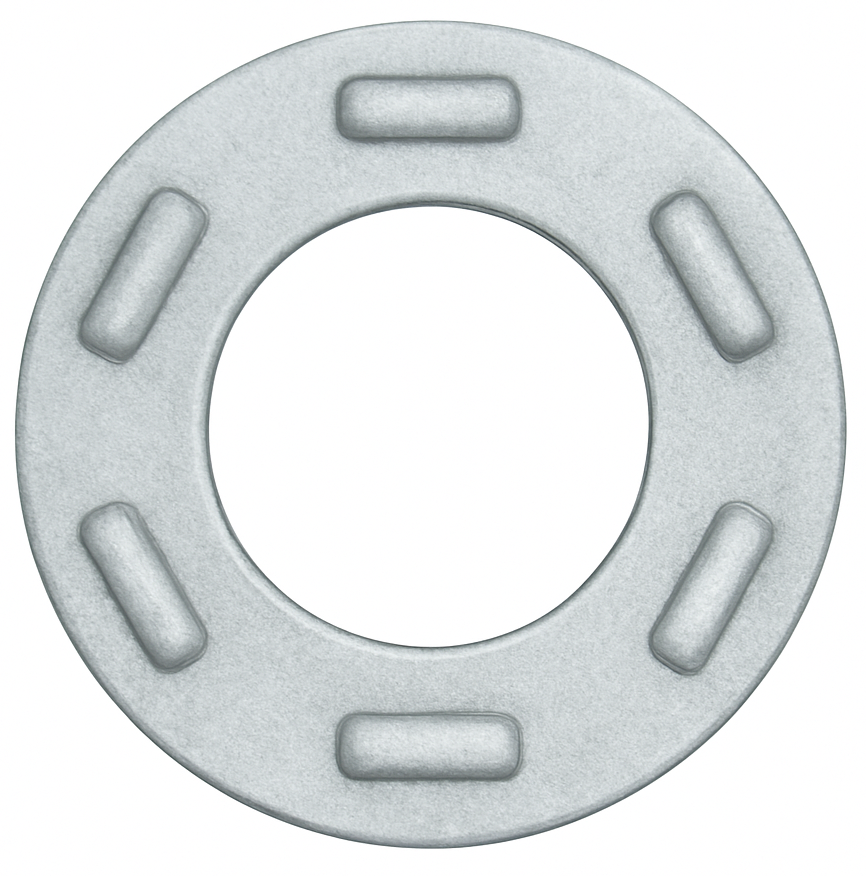

Load-Indicating Washer

A load-indicating washer is a special washer that tells you when a bolted joint has reached the required preload. The most common type is the direct-tension-indicator (DTI) used with structural bolts: one face of the washer has small compressible protrusions (“bumps”). As you tighten the joint, those bumps flatten in a controlled way; when they’re compressed to a specified gap, the bolt has achieved at least the minimum tension. Inspectors verify this by checking the remaining gap with a thin feeler gauge, or—on “squirter” DTIs—by looking for a ring of colored silicone that extrudes at the correct load.

DTIs move quality control from torque (which is affected by friction) to actual bolt tension at the joint. They’re widely used in steel construction and heavy fabrications to verify preload on high-strength bolts, and they complement other methods like calibrated wrench and turn-of-nut. They don’t keep a joint tight by themselves (they are not lock washers); they simply indicate that the required tension was achieved during installation.

Proper installation is essential. You select a washer matched to the bolt size/grade, seat the protrusions against a flat, hardened bearing surface—either under the bolt head or under a hardened flat washer beneath the nut, exactly as the manufacturer specifies—and tighten from snug to final tension until the gauge check passes or the silicone shows. After you first load the connection, you re-check and re-torque if required. DTIs are generally single-use items and are not meant for continuous load monitoring; if you need ongoing measurement, you’d use load-monitoring bolts or instrumented load washers instead.

Lock Nut

A type of fastener designed to resist loosening caused by excessive vibration. Lock nuts employ various locking mechanisms, including nylon inserts, distorted threads, or metal deformation, to maintain a secure hold. They are commonly used in applications that experience high levels of movement and must remain tight despite these changing forces.

Lock Washer DIN 127B

A Lockwasher DIN 127B is a split lock washer (also known as a helical spring lock washer) designed according to the DIN 127B standard, which defines the dimensions, materials, and specifications for this type of lock washer. It is commonly used to prevent fasteners from loosening due to vibration or dynamic loads.

Lockbolt

A lockbolt is a high-strength, two-piece, permanent fastener made of a pin and a collar. During installation, the pin is inserted through the joint and the collar is placed over the pin’s grooved shank. A hydraulic/pneumatic tool then pulls on the pin while swaging (cold-forming) the collar into the grooves; when the correct clamp is reached, the tool snaps off the pin’s pintail at a predetermined break point. The result is a solid, vibration-proof mechanical lock between collar and pin—no torque or thread friction is relied on, so clamp load is very consistent and doesn’t loosen in service.

Lockbolts come in shear and tensile (structural) styles with various head forms and materials (steel, stainless, aluminum). They’re widely used in trucks and trailers, railcars, heavy equipment, bridges, and wind towers—anywhere you need high fatigue resistance and fast, repeatable assembly. Standard lockbolts require access to both sides of the joint and special tooling, and removal typically means drilling or splitting the collar; “blind lockbolts” exist for one-side access.

Loctite®

Loctite® is Henkel’s well-known line of industrial adhesives and sealants, best recognized for anaerobic threadlockers that cure without air when confined between metal threads. Brushed onto a bolt or nut, the liquid fills thread gaps, then polymerizes with the help of metal ions to lock the joint against vibration, seal out leaks and corrosion, and help maintain clamp load. Grades vary by strength and behavior: purple is low strength for tiny screws, blue is medium and removable with hand tools (243 is oil-tolerant), red is high strength and typically needs heat to break, and green is a thin “wicking” formula that penetrates pre-assembled fasteners.

Beyond threadlockers, the Loctite brand also includes retaining compounds for shafts and bearings, pipe thread sealants, gasketing products, cyanoacrylate instant adhesives, epoxies, structural acrylics, and silicones. Performance—such as temperature limits, oil tolerance, and cure speed—depends on the specific grade and substrate, and primers can help on passive metals like stainless or zinc-plated parts.

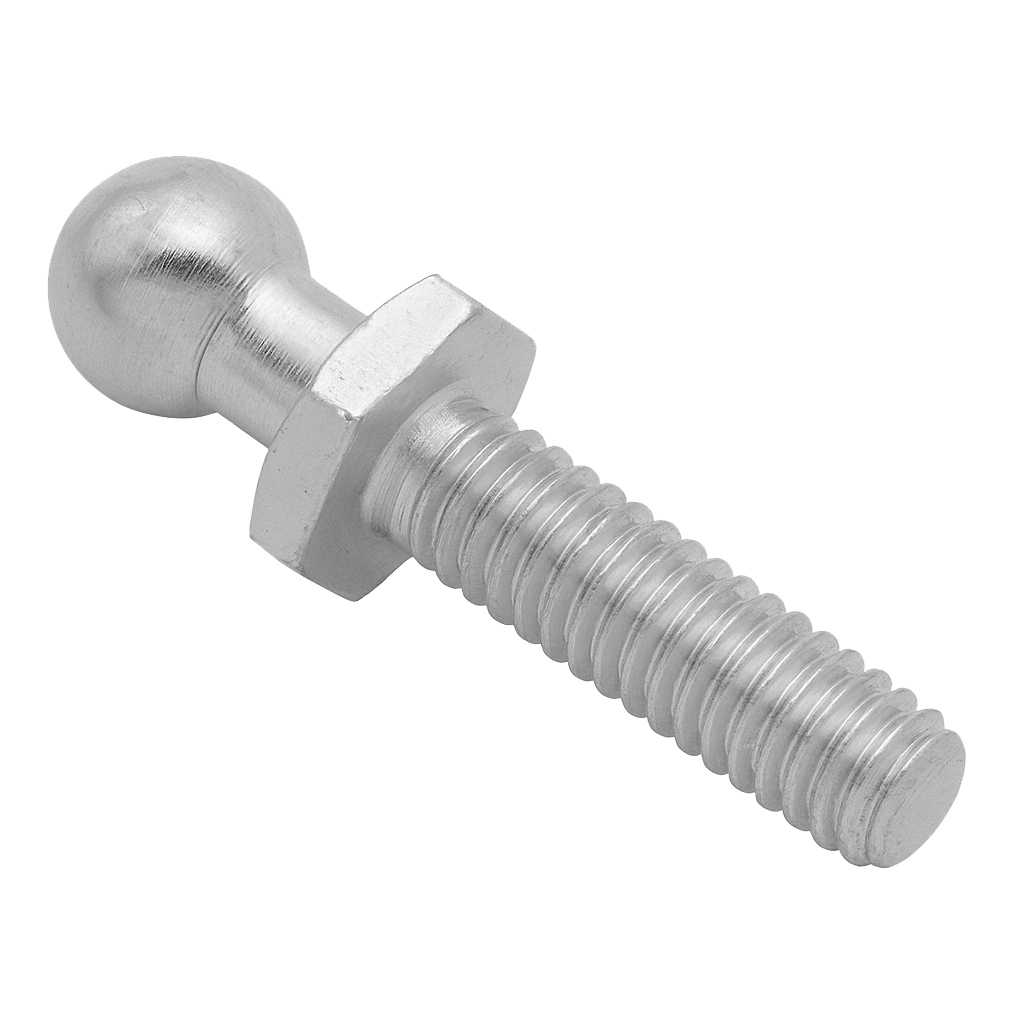

Long Shank Ball Stud

A long shank ball stud is a type of mechanical fastener featuring a spherical ball end on one side and an extended threaded shank on the other. It’s designed to serve as the pivot or attachment point in a ball-and-socket joint, allowing controlled movement and articulation between connected components. The “long shank” portion refers to the elongated threaded or unthreaded section of the stud, which provides additional reach, spacing, or mounting depth compared to standard ball studs.

In design, a ball stud typically consists of a hardened steel or stainless steel ball that forms a smooth bearing surface, often paired with a nylon, steel, or polymer socket that can swivel around it. The threaded shank allows the stud to be securely fastened to a bracket, housing, or linkage, while the ball end provides rotational or angular movement. The long shank version extends the distance between the ball and the mounting surface, offering more flexibility in assembly layouts or accommodating thicker materials and deeper mounts.

Long shank ball studs are commonly used in automotive, industrial, and mechanical applications, particularly where motion control and articulation are required. In the automotive industry, they appear in suspension systems, steering linkages, hood and trunk lift supports (gas struts), throttle linkages, and seat mechanisms. The extended shank allows them to reach mounting points that are recessed or spaced farther apart, maintaining proper motion geometry. In industrial machinery, they are used in linkages, actuators, and automation systems where parts must pivot, tilt, or adjust under load.

These studs are often manufactured from high-strength alloy steel, stainless steel, or zinc-plated carbon steel for corrosion resistance and durability. The ball is usually polished or chrome-plated to reduce friction and wear. Some designs include a grease fitting (zerk) or are self-lubricating, ensuring smooth long-term operation.

Lot

A specific quantity of fasteners that are manufactured, processed, or packaged under the same conditions and grouped together for identification and quality control. A lot typically shares the same material, production run, heat treatment, and inspection records to ensure consistency and traceability.

Lot Sampling

A quality control method used to evaluate a batch (or “lot”) of fasteners by inspecting a representative subset. Instead of testing every item, a specific number of parts are randomly selected and checked for defects or compliance with specifications. The results help determine whether the entire lot meets quality standards or needs to be rejected or reprocessed.

Lubricity

Lubricity in terms of fasteners refers to how easily two surfaces slide over one another when a fastener, such as a bolt, screw, or nut, is tightened. It describes the frictional characteristics of the fastener’s threads and bearing surfaces, which directly affect the relationship between the applied torque and the resulting clamping force (preload) in a joint.

When a fastener is tightened, most of the torque applied—often 80–90%—is consumed in overcoming friction between the threads and under the head or nut. Only the remaining portion is converted into actual bolt tension that clamps the joint. A fastener with high lubricity (low friction) requires less torque to achieve the same clamping force, while a fastener with low lubricity (high friction) requires more torque and may result in inconsistent preload.

Lubricity can be influenced by coatings, platings, or added lubricants. For example, zinc plating, phosphate coatings, PTFE (Teflon), or ceramic coatings may reduce friction, while dry, rusty, or damaged threads increase friction and reduce lubricity. Consistent lubricity is critical in precision applications, such as aerospace, automotive, or pressure vessel fastenings, where preload accuracy determines safety and performance.

Lug Bolt

A lug bolt is a fastener used to secure a wheel directly to a vehicle’s hub. It serves the same purpose as a lug nut but differs in design because it combines the threaded portion and the clamping head into a single piece. Instead of relying on a separate stud-and-nut system, the lug bolt passes through the wheel and threads directly into a tapped hole in the hub to hold the wheel firmly in place.

Lug bolts are generally manufactured from high-strength alloy steel or hardened steel to withstand the extreme stresses of driving and braking. They are often plated or coated to improve corrosion resistance. The bolt includes a threaded shank that engages with the hub and a head with a seating surface designed to match the wheel. The seat type may be conical (tapered), spherical (ball seat), or flat, depending on the wheel’s lug hole design. In many cases, lug bolts also include a captive washer that helps distribute the load and protect the wheel surface from damage.

The purpose of a lug bolt is to secure the wheel to the hub without using wheel studs and separate nuts. This simplifies the overall hub and wheel assembly, though it requires precise torque application during installation. Proper tightening is critical to achieve the correct preload, maintain even clamping force across all wheel bolts, and prevent problems such as loosening, vibration, or wheel detachment.

Lug bolts are most commonly found on European vehicles, with manufacturers such as BMW, Volkswagen, Audi, and Mercedes-Benz frequently using them. They are also seen in other passenger vehicles and light trucks where the hub is designed with tapped holes. In aftermarket applications, some wheels built for lug bolt systems may include alignment guides or design features that make installation easier.

There are several advantages to using lug bolts. They reduce the number of parts since there is no need for separate studs and nuts, and they offer a cleaner appearance because only the bolt heads are visible on the wheel face. When installed to the proper torque specification, lug bolts are strong and secure. However, they also present limitations. Mounting wheels can be more difficult because the wheel must be held in place while the bolts are inserted and threaded. There is also a greater risk of cross-threading when starting the bolts in the hub, and wheel changes or tire swaps often take more time compared to traditional stud-and-nut systems.

Lynch Pin

A lynch pin (often spelled linchpin) is a quick-release retaining pin with an integral spring-locking ring used to keep a shaft, hitch pin, or clevis pin from sliding out. The pin has a groove near its end, and a hinged wire ring snaps over this groove to lock the pin in place. Removal is tool-free—flip the ring open and pull the pin.

How it works: insert the pin through the aligned holes of the parts being fastened (for example, a drawbar and trailer tongue). Rotate the spring ring down until it snaps into the groove; the ring’s spring tension prevents the pin from backing out under vibration.

Where it’s used: lynch pins are common on agricultural 3-point hitches, trailers and towing hardware, landscaping and construction equipment, and material-handling fixtures—any application requiring frequent, tool-free assembly and disassembly.

Construction and options: pins are typically made from low-carbon or alloy steel with zinc plating, or from stainless steel for corrosion resistance. Common diameters range from 1/4″ to 5/8″ with various usable lengths. Variants include safety chains or tethers, different ring sizes, and heavy-duty styles.

Notes and distinctions: a hitch pin is the straight load-bearing pin, while the lynch pin is the spring-locking retainer (some designs integrate both). Lynch pins are intended for shear/retention in general equipment and not for overhead lifting. Choose a size that closely fits the hole and ensure the ring is fully seated in the groove.