Resources

Glossary

T-Head Bolt

An industrial T-head bolt (or T-bolt) is a type of fastener with a T-shaped head, designed to be inserted into a slot or groove and turned 90 degrees to lock into place. The "T" shape allows the bolt head to sit flush or slightly recessed in the material it is fastening, providing a secure hold without the need for additional tools to hold the bolt in place during tightening. These bolts are commonly used in applications where the fastener needs to be quickly and easily inserted into a channel or slot.

Tab Locking Washer

Tab Locking Washers (also called tab washers or lock tabs) are specialized washers designed to prevent fasteners—such as bolts or nuts—from loosening due to vibration or rotation. They achieve this by physically locking the fastener in place using one or more bendable tabs.

Tam Anchor

A tam anchor is a mechanical expansion anchor (typically a sleeve/shield-style anchor) used to fasten fixtures into concrete, brick, or masonry. It is installed in a drilled hole and then tightened to expand the metal sleeve/shield against the hole wall, creating holding power by friction and bearing.

How it works

- A typical tam anchor assembly includes a bolt (often hex head), an expansion sleeve/shield, and a cone.

- When you apply torque, the cone is pulled into the sleeve, forcing the sleeve to expand against the drill hole wall.

Common variations

- Loose bolt / projecting bolt styles (depending on whether the bolt is removable/replaceable and how much thread remains exposed).

- Hook or eye versions (same “TAM design” paired with a hook/eye for hanging and utility fixings).

Typical applications

- Light to heavy fixings in concrete/brick/masonry (fixtures, brackets, supports).

- Many catalogs group “TAM” anchors under heavy-duty mechanical anchors supplied with bolt and washer (often galvanized carbon steel, with common bolt strengths like class 8.8 in some product lines).

AKA: Tam Shield Anchor

Tantalum (Ta)

Tantalum (chemical symbol Ta) is a hard, dense, blue-gray metallic element known for its exceptional corrosion resistance, high melting point, and excellent conductivity. It is one of the refractory metals, meaning it can withstand extremely high temperatures without losing strength or stability. Tantalum’s atomic number is 73, and it sits in Group 5 of the periodic table, alongside niobium (Nb), vanadium (V), and other transition metals with similar properties.

Tantalum is characterized by its high melting point of about 3,017°C (5,463°F), which makes it one of the most heat-resistant metals known. It also exhibits high ductility and toughness, even at low temperatures, and can be easily fabricated into fine wires or thin sheets. Chemically, tantalum is remarkably inert—it does not react with most acids, including hydrochloric and sulfuric acid, and only dissolves in hydrofluoric acid or molten alkalis. This outstanding corrosion resistance is due to the formation of a stable oxide layer (Ta₂O₅) on its surface, which protects it from chemical attack.

Because of these properties, tantalum is widely used in electronics, aerospace, chemical processing, and medical applications. One of its most important uses is in tantalum capacitors, where its oxide layer serves as a highly efficient dielectric. These capacitors are compact, reliable, and stable, making them essential in smartphones, computers, automotive electronics, and military equipment. In the aerospace and chemical industries, tantalum is used for heat exchangers, reactor vessels, and piping, particularly in environments where acids or corrosive chemicals would destroy other metals.

Tantalum is also valuable in the alloying industry, where it enhances strength, ductility, and oxidation resistance in superalloys used for jet engines, turbines, and nuclear reactors. In medicine, it’s used for surgical implants, prosthetics, and bone repair because it’s biocompatible and does not react with body fluids.

Most tantalum is mined from tantalite ore (Fe,Mn)(Ta,Nb)₂O₆, which often contains niobium, a closely related element. The major sources are found in Africa (particularly the Democratic Republic of Congo, Rwanda, and Nigeria), Australia, and Brazil. However, the mining of tantalum has raised ethical concerns due to its association with conflict minerals, leading to global efforts to ensure responsible sourcing.

Tap and Die Set

A tap and die set is a collection of tools used to cut, repair, or clean screw threads, which are the helical grooves that allow bolts, screws, and nuts to fasten securely. These sets are widely used in metalworking, automotive repair, maintenance, and fabrication because they make it possible to either create new threads or restore damaged ones.

The tap is the tool used for cutting or forming internal threads inside a hole so that a screw or bolt can be inserted. Taps are typically made of hardened steel and have flutes cut along their length, which allow chips of material to escape during the cutting process. They come in several variations: taper taps for starting threads easily, plug taps for cutting closer to the bottom of a hole, and bottoming taps for completing threads at the very bottom of blind holes.

The die is used to cut or repair external threads on rods, bolts, or pipes. Shaped as a round or hexagonal tool with sharp cutting edges, a die matches specific thread sizes and pitches. It is typically mounted into a die stock handle, which provides the leverage needed to rotate it around the material being threaded.

Together, taps and dies serve two main functions: creating new threads in raw material or repairing existing ones that have been damaged by rust, wear, or mishandling. They are also used for chasing threads to clean and realign them, ensuring smooth assembly.

These tools have many applications, such as fixing spark plug holes in automotive repair, restoring fasteners in general maintenance, cutting custom-sized threaded parts in metalworking, or threading rods and pipes in construction and plumbing. Their versatility makes them a cost-effective solution for extending the life of parts and avoiding replacements.

While highly useful, tap and die sets do have limitations. They require precise alignment to avoid cross-threading, may weaken softer or thin materials when used incorrectly, and are not efficient for high-volume industrial thread production, which relies on automated machinery. Nonetheless, they remain an essential part of most toolkits for repairing and creating threaded fasteners.

Tap Bolt

A tap bolt is a type of fully threaded hex-head bolt that is designed to be inserted into a tapped (threaded) hole or used with a nut. It looks similar to a hex cap screw but lacks the washer face under the head and may not have the same tight tolerances.

Tap End Stud Bolt

A Tap End Stud Bolt is a type of stud bolt that has unequal thread lengths on each end and is specifically designed for installation into tapped (threaded) holes on one end and to accept a nut on the other.

Tee Nuts

A tee nut (also spelled T-nut) is a type of fastener used to provide a strong, reliable threaded socket in wood, particle board, or composite materials. It's especially common in furniture, woodworking, and climbing wall construction.

Teflon (PTFE) O-Rings

Teflon (PTFE) O-rings are sealing rings made from polytetrafluoroethylene (PTFE), a synthetic fluoropolymer best known by the brand name Teflon. These O-rings are used in applications where chemical resistance, high temperature tolerance, and low friction are critical.

Tellurium (Te)

Tellurium is a metalloid element with the chemical symbol Te and atomic number 52. It shares properties with both metals and nonmetals, sitting alongside selenium and sulfur in the periodic table. Tellurium is silvery-white, brittle, and crystalline, and it has a metallic luster. Though it conducts electricity, it does so poorly at room temperature—its conductivity increases when heated, a hallmark of semiconductors.

In nature, tellurium is extremely rare, ranking among the least abundant elements in Earth’s crust. It is typically found in combination with other metals such as gold, silver, copper, and lead, forming telluride minerals (e.g., calaverite and sylvanite). Because of this, most tellurium is obtained as a byproduct of copper refining, where it is recovered from anode slimes formed during electrolysis.

Chemically, tellurium behaves like selenium and sulfur, forming oxides, halides, and tellurides. It burns in air with a blue flame, producing tellurium dioxide (TeO₂), and it reacts with metals to form compounds used in thermoelectric devices. Tellurium’s most important application is in semiconductor technology, especially in cadmium telluride (CdTe) solar cells, which convert sunlight into electricity efficiently and cost-effectively. It’s also used in thermoelectric materials, where it helps generate power from heat differentials, and in phase-change memory devices used in modern data storage.

In metallurgy, small amounts of tellurium are added to steel, copper, and lead alloys to improve machinability and corrosion resistance. Tellurium enhances the strength, hardness, and durability of these alloys without compromising ductility. It also finds use in rubber vulcanization, glass tinting, and ceramic pigments.

One interesting aspect of tellurium is its distinct garlic-like odor—a characteristic that can persist in the breath or sweat of people exposed to it. While toxic in large doses, trace amounts of tellurium compounds are sometimes used in specialized chemical and industrial applications.

Tensile Ductility Test

A Tensile Ductility Test is a standardized method used to measure how well a material can stretch, elongate, and undergo plastic deformation under a pulling force before it breaks. It provides key information about the ductility, toughness, and overall performance of a material when subjected to tension.

During the test, a specimen such as a machined metal rod, fastener, or another standardized piece is placed in a tensile testing machine. The machine gradually applies a pulling force along the specimen’s axis until the material deforms and eventually fractures. Throughout the test, important data is recorded, including the elongation of the specimen, which shows how much it lengthens as a percentage of its original length, the reduction of area at the fracture point caused by necking, and the full stress-strain behavior, which illustrates the relationship between applied stress and strain from the yield strength through the ultimate tensile strength and finally to fracture.

The purpose of the Tensile Ductility Test is to evaluate how a material responds when exposed to tensile loads. Materials with high tensile ductility, such as mild steel or aluminum, are able to stretch significantly before breaking, while more brittle materials like cast iron or hardened steel fracture with very little elongation.

This type of test is widely used in fastener manufacturing, structural engineering, and materials science. For fasteners in particular, it ensures that bolts, screws, and other components have the toughness required to deform safely without failing suddenly under load, thereby verifying their reliability in real-world applications.

Tensile Strength

Tensile strength is the maximum amount of tensile (pulling) stress that a material can withstand before it breaks or fractures. It represents the point on a stress–strain curve where the material reaches its ultimate ability to resist stretching under load. Beyond this limit, the material begins to neck, deform irreversibly, and eventually fail.

In fasteners such as bolts, screws, and rods, tensile strength is one of the most critical mechanical properties. It defines how much tension the fastener can endure before breaking and is usually expressed in megapascals (MPa) or pounds per square inch (psi). For example, a steel bolt with a tensile strength of 800 MPa can withstand a maximum stress of 800 million newtons per square meter before fracturing.

The tensile strength of a fastener is determined through testing, where a sample is gradually pulled apart in a tensile testing machine until it fails. During this process, the material first deforms elastically (it stretches but returns to its original shape), then plastically (it stretches permanently), and finally fractures when the tensile strength is exceeded.

Tensile strength is often used alongside yield strength and proof load to describe a material’s behavior under stress. While proof load represents the maximum stress a fastener can handle without permanent deformation, tensile strength marks the absolute breaking point. For high-strength fasteners—such as those made to grades 8.8, 10.9, or 12.9—the tensile strength can range from 800 MPa to 1,200 MPa or higher, depending on the material and heat treatment.

In summary, tensile strength is a measure of how much pulling force a material can sustain before failure. It is a fundamental indicator of mechanical performance, reliability, and safety in fasteners and structural components, ensuring that parts can resist breaking under load in service conditions.

Tension Control Bolt

A tension control (TC) bolt—often called a twist-off bolt—is a pre-assembled structural fastener used to achieve a precise, verified clamp load in steel construction. The assembly has a round-head bolt with a splined “pintail” on the threaded end, a heavy-hex nut, and usually a washer. During installation a special shear wrench grips the nut and the spline; as the tool turns, the joint is tensioned. When the specified preload is reached, the spline snaps off at a calibrated groove, leaving a flush end and giving an instant visual check that the bolt is properly pretensioned.

TC bolts are popular on bridges and steel buildings because they’re fast, consistent, and easy to inspect. They’re generally single-use (after the pintail breaks) and require the proper wrench and procedures. In U.S. specs, common equivalents are ASTM F1852 (roughly A325 strength) and ASTM F2280 (roughly A490 strength). If you’d like, I can render a crisp, ultra-white image of a TC bolt assembly showing the splined end before and after the break.

Terminal Strip

A terminal strip, also known as a terminal block, is an electrical connector assembly used to join two or more wires together in a safe, organized, and serviceable way. It provides a mechanically secure and electrically conductive connection point, allowing multiple circuits to be connected, disconnected, or maintained without cutting or splicing wires.

Structurally, a terminal strip consists of a series of metal terminals (usually made of brass, copper, or a conductive alloy) that are mounted within an insulated base, often made from plastic, phenolic resin, or ceramic. Each terminal provides a connection point for incoming and outgoing conductors, keeping them electrically isolated from each other while maintaining excellent conductivity within each circuit.

There are several common types of terminal strips, each suited to specific electrical needs:

- Screw-type terminal strips, where wires are secured under screws or clamps—common in control panels and general electrical work.

- Stud-type terminal strips, which use threaded posts and nuts to attach ring or fork terminals—often used in high-current or industrial power systems.

- Spring-clamp terminal strips, which hold wires in place using a spring mechanism—preferred for quick installation and vibration resistance.

- Barrier terminal strips, which include raised insulating dividers between terminals to prevent accidental shorts or contact.

Terminal strips are used in control panels, junction boxes, machinery, automotive and marine electrical systems, HVAC units, and power distribution panels. Their modular design allows for easy expansion and maintenance—wires can be replaced, tested, or rearranged without disturbing the rest of the system.

Thermal Conductance

Thermal conductance is a measure of how easily heat flows through a material or object when there is a temperature difference across it. In simple terms, it tells us how good something is at letting heat pass through. The higher the thermal conductance, the more efficiently heat is transferred; the lower the thermal conductance, the more the material resists heat flow.

In fastener and mechanical applications, thermal conductance is important because it influences how heat spreads through joints, bolts, washers, and connected assemblies. Good thermal conductance helps prevent localized overheating, while poor conductance may cause thermal stress or uneven expansion.

Thermal Cycling

Thermal cycling is the repeated heating and cooling of a component, assembly, or joint as it moves between different operating temperatures over time. Each cycle causes the materials to expand when heated and contract when cooled, and because different materials (and even different sections of the same assembly) expand at different rates, the cycling creates repeated changes in stress, fit, and contact pressure.

In bolted joints and sealing applications, thermal cycling is important because it can change bolt preload and gasket stress from cycle to cycle. Differential expansion between bolts, flanges, and the clamped parts can temporarily increase or decrease clamp load, and repeated cycling can lead to embedment, creep/relaxation of softer materials, and gradual loss of sealing stress. Over time, thermal cycling can also contribute to fatigue damage (cracking) in fasteners or components, especially where stress concentrations exist, and it can accelerate issues like gasket leakage, loosening, or distortion if the joint design and materials aren’t matched to the temperature swings.

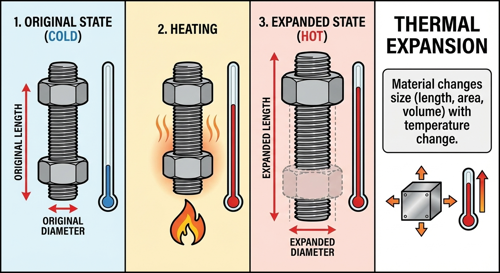

Thermal Expansion

Thermal expansion, in the context of engineering and fasteners, is the tendency of any material to change its size—specifically its length, area, or volume—in direct response to a change in temperature. When a component is heated, its constituent atoms vibrate more energetically and move further apart, resulting in physical expansion. Conversely, cooling the component causes the atoms to slow down and move closer together, leading to contraction. This fundamental property is measured by the Coefficient of Thermal Expansion (α), a value unique to each material. The amount a component's length changes is proportional to its original length, the temperature change, and this coefficient.

Calculating Thermal Expansion

The change in length (ΔL) of a component due to a change in temperature (ΔT) can be calculated using a linear expansion formula.

Change in Length=Coefficient of Thermal Expansion×Original Length×Change in Temperature

Impact on Fastened Joints

Understanding thermal expansion is critical in fastener design, particularly when a joint involves multiple materials. This phenomenon, known as Differential Thermal Expansion, occurs when the fastener (e.g., a steel bolt) and the materials it clamps (e.g., aluminum flanges) have different coefficients of thermal expansion (α). If the bolt expands or contracts at a different rate than the clamped material, it can create two significant problems. The first is a loss of clamp load, where the joint loosens because the component expands more than the bolt, a common failure point. The second is the generation of excessive stress, where a highly expansive bolt can over-tighten and crush the clamped components. Engineers mitigate these risks by carefully selecting materials with closely matched α values or by incorporating elastic elements like compression washers to absorb the inevitable dimensional changes.

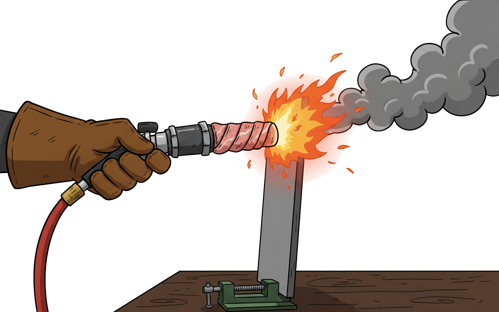

Thermal Lancing

Thermal lancing—also known as an oxy-thermic cutting process or oxygen lance cutting—is a high-temperature cutting method used to slice through extremely tough materials such as steel, cast iron, concrete, and refractory linings. Instead of relying on mechanical force or conventional oxy-fuel flames, a thermal lance uses a hollow steel tube filled with iron rods or wires, through which pressurized oxygen is blown. When the end of the lance is ignited, the steel inside reacts violently with the oxygen in a process known as oxidation, generating temperatures that can exceed 4,000°C (7,200°F)—hot enough to melt or vaporize nearly any known material.

The process works as follows: the operator first initiates combustion at the lance tip using an external heat source such as an oxy-acetylene torch. Once ignited, oxygen flows through the steel tube, feeding the reaction between the steel and oxygen to sustain a continuous burn. This intense heat melts the target material, and the high-velocity oxygen jet blows the molten residue away, leaving a clean cut or bore.

Thermal lancing is especially useful in industrial demolition, foundry work, and maintenance operations where conventional cutting methods fail. It is commonly used to:

- Cut through large steel sections such as shafts, pins, or anchors.

- Pierce concrete or rock reinforced with steel rebar.

- Remove seized or damaged components in heavy machinery.

- Open furnace tap holes or cut slag in metallurgical operations.

Unlike oxy-fuel cutting—which depends on preheating and oxidation of the base material—thermal lancing can cut any conductive or non-conductive material, regardless of its composition or thickness. This makes it particularly valuable in emergency or salvage operations where other tools cannot penetrate.

However, thermal lancing has some drawbacks. It is labor-intensive, produces molten slag and sparks, and can damage surrounding material due to the extreme heat. It also consumes large amounts of oxygen and requires careful safety precautions to manage the intense flame and molten discharge.

AKA: Oxy-Thermic Cutting Process or Oxygen Lance Cutting

Thermal Stress

Thermal stress is the internal stress that develops within a material when it experiences a change in temperature that causes it to expand or contract. Because different parts of the material may heat or cool at different rates—or because the material’s expansion is physically constrained—uneven thermal expansion or contraction generates internal forces. These forces resist the dimensional changes and create stress within the structure.

When a material is heated, it tends to expand, and when cooled, it contracts. The amount of expansion or contraction depends on the coefficient of thermal expansion (α), the temperature change (ΔT), and the original dimensions of the object. If this movement is restricted (for example, by fasteners, joints, or other structural components), the material cannot freely deform, and internal stress builds up. The basic relationship for thermal stress in a fully constrained material is:

σ = EαΔT

where 𝜎 is the thermal stress, 𝐸 is the modulus of elasticity, 𝛼 is the coefficient of thermal expansion, and

Δ𝑇 is the temperature change.

If the temperature increases, the material wants to expand. When expansion is prevented, compressive stress develops. Conversely, if the temperature decreases and contraction is restrained, tensile stress occurs. Over time, repeated heating and cooling cycles can lead to thermal fatigue, a form of failure caused by the continual buildup and release of these stresses, often resulting in microcracks that grow with each cycle.

Thermal stress is particularly critical in metals, ceramics, and composite materials used in environments with large temperature gradients, such as turbine blades, engines, bridges, piping systems, and electronic components. For example, in a steel bridge exposed to day-night temperature swings, expansion during the day and contraction at night create alternating stresses that must be accounted for in the design.

Designers manage thermal stress by allowing for expansion (using expansion joints or flexible connections), selecting materials with compatible coefficients of thermal expansion, or applying thermal treatments that reduce residual stresses.

Thimble Eye Bolt

A thimble eye bolt is a type of lifting or anchoring bolt designed with an integrated thimble-shaped eye that provides a smooth, rounded surface for attaching wire rope, cable, or chain. The thimble eye is formed to mimic the shape of a thimble used in wire rope terminations, which helps protect the rope or cable from abrasion, kinking, and wear when tension is applied.

Structurally, a thimble eye bolt consists of a threaded shank (for mounting into a tapped hole, nut, or structure) and a forged eye at the head with a reinforced, curved interior surface. The curved “thimble” shape evenly distributes load stress across the rope or cable loop, reducing bending fatigue and extending the life of the connection.

Thimble eye bolts are commonly used in lifting, rigging, and guying applications—for example, on utility poles, structural supports, marine hardware, and industrial lifting assemblies—where wire rope or strand must remain aligned with the direction of load.

They are typically made from forged carbon steel or stainless steel and often hot-dip galvanized or zinc-plated for corrosion resistance, especially in outdoor or marine environments.

Thin Nylon Insert Lock Nut DIN 985

The dimensional standard DIN 985 calls the nylon insert lock nuts in this standard as “thin” but this designation is not the same as the inch series thin nuts NTE. DIN 985 lock nuts have a thickness that is equivalent to the bolt diameter they are designed to be used on (example an M10 nut per this spec will be 10mm thick). These are called “thin” nuts because they are thinner than nylon insert lock nuts made to DIN 982 or DIN 6924. Thin nylon insert lock nuts in inch sizes (NTE series) are about half as thick as a DIN 985 nut.

Thread Angle

The thread angle is the angle formed between the two flanks of a thread, measured in an axial plane. In simple terms, if you look at a thread cross-section, the thread angle is the included angle at the base of the thread, where the two sloping sides (the flanks) meet. It defines the overall geometry of the thread profile and plays a key role in how the load is carried, how the threads engage, and how resistant they are to loosening or failure.

Different thread standards specify different thread angles depending on their purpose. For example, Unified (UN) and ISO metric threads both use a 60° thread angle, which is now the most common globally. British Standard Whitworth threads use a 55° angle, giving them a slightly rounder profile. Acme threads have a 29° angle, designed for power transmission and heavy load applications, while buttress threads use an asymmetric angle to handle high loads in one direction.

The choice of thread angle affects strength, friction, and efficiency. Larger thread angles provide more strength and easier manufacturing but can generate more friction. Smaller or specialized angles are chosen to balance strength with performance in specific applications. Ultimately, the thread angle is one of the defining features of a thread system, ensuring compatibility and proper function between mating parts.

Thread Chaser

A thread chaser is a tool designed to clean, repair, and restore existing threads on bolts, screws, nuts, or tapped holes. Unlike taps and dies, which are made to cut new threads, a thread chaser works by reforming and clearing damaged or dirty threads without removing significant amounts of material. This helps maintain the strength of the fastener while making it functional again.

Thread chasers come in several forms. Some are hand tools shaped like small files with ridged teeth that match the pitch of threads. Others are tap- and die-style chasers, which look like cutting tools but are made to clean rather than cut. There are also thread-restoring files with multiple pitches for external threads, and full thread chaser kits that contain both internal and external chasers in common metric and imperial sizes.

The purpose of a thread chaser is to restore damaged or dirty threads so fasteners can be reused reliably. They clean out rust, dirt, paint, or minor deformities, reshaping the threads so nuts and bolts fit smoothly. Because they don’t aggressively cut new material, they preserve more of the fastener’s original strength compared to using taps or dies.

Thread chasers are widely used in automotive repair, where they can clean spark plug threads, lug studs, or engine block holes. They are also valuable in maintenance, fabrication, and assembly work to extend the life of fasteners exposed to wear or corrosion. Their advantages include being quick to use, cost-effective, and able to extend the life of expensive or hard-to-replace components.

However, they do have limitations. Thread chasers cannot fix threads that are completely stripped or missing, nor can they create new threads. Their use is also limited by the sizes and thread pitches available in a given tool set. Despite these restrictions, they remain an essential tool for restoring fastener function without weakening parts unnecessarily.

Thread Class

A designation that defines the tolerance and fit of a thread, consisting of a number and a letter. The number (1, 2, or 3) indicates the tolerance level with 1 being loose fit, 2 standard fit, and 3 tight fit. The letter indicates the thread type, with A for external threads (such as bolts) and B for internal threads (such as nuts).

Thread Crest

The thread crest is the topmost surface of a thread, the peak or ridge that forms the highest point on a screw, bolt, or nut. If the thread root represents the valley between threads, then the crest is the mountain peak. On an external thread, such as a bolt, the crest is the outermost edge of the threads that you can see and feel. On an internal thread, such as inside a nut, the crest is the innermost edge of the cut thread profile.

The shape of the crest is an important factor in ensuring proper fit and strength. In many modern thread standards, crests are designed to be flat, as this reduces stress concentration and improves durability. In some applications, crests may be rounded to further reduce sharp edges that could weaken the fastener and make it more prone to wear. Older or non-standard thread forms often used sharp crests, but these tend to be weaker because sharp edges are more vulnerable to damage.

Together with the flanks, which are the angled sides of the thread, and the root, which is the valley at the bottom, the crest defines the complete thread profile. Its geometry plays a vital role in how well two threaded parts engage and how effectively they can carry loads without loosening, wearing, or failing.

Thread Cutting Screws

An industrial thread cutting screw is a type of fastener designed to create its own threads when driven into a material, typically metal, wood, or plastic. Unlike screws that require a pre-tapped hole with existing threads, thread cutting screws have a sharp, cutting edge or flute on their tip or threads that removes material as the screw is driven in, forming a mating thread in the process.

Thread Flank

The thread flank is the angled surface that connects the crest (the top of the thread) to the root (the bottom of the thread). In other words, it is the sloping side of each thread ridge, forming the surface that actually makes contact with the mating thread when a bolt is screwed into a nut.

The angle and precision of the flanks are critical because they determine how load is distributed across the threads. When a fastener is tightened, the majority of the clamping force is transferred through the contact between the flanks of the internal and external threads. If the flank angle is incorrect or the surfaces are poorly formed, it can lead to uneven stress, premature wear, or failure of the fastener.

Different thread standards specify exact flank angles. For example, Unified and ISO metric threads typically use a 60° flank angle, while other forms such as Acme or buttress threads use different geometries to handle specific load conditions. In all cases, the flank is where the functional strength of the thread lies, making it one of the most important elements in fastener design.

Thread Pitch

Thread pitch is the distance between corresponding points on adjacent threads of a screw, bolt, or nut. In simple terms, it measures how far a fastener will travel linearly in one complete turn.

In metric threads, thread pitch is expressed directly in millimeters (mm). For example, an M10 × 1.5 bolt has a pitch of 1.5 mm, meaning the bolt advances 1.5 mm with each full revolution.

In the inch-based Unified Thread Standard (UTS) used in the U.S., pitch is usually described indirectly as threads per inch (TPI). For instance, a 1/4-20 UNC bolt has 20 threads per inch, which corresponds to a pitch of 1/20 = 0.050 inches.

Pitch is one of the key dimensions that determines whether threaded parts will mate properly. A mismatch in thread pitch, even if the diameter looks correct, will prevent proper engagement and can cause damage, stripping, or failure.

Engineers carefully specify thread pitch depending on the application. Coarse pitches (fewer threads per inch or larger millimeter pitch) are stronger and faster to assemble, while fine pitches (more threads per inch or smaller millimeter pitch) allow for greater precision, better load distribution, and stronger resistance to loosening under vibration.

Thread Root

The thread root is the lowest part of a thread, located between the flanks of adjacent threads on a screw, bolt, or nut. If you look at the “valleys” between the raised portions of the thread (the crests), that bottom surface is the root.

The geometry of the thread root is important because it affects both the strength and fatigue resistance of a fastener. Sharp roots can act as stress concentrators, making the fastener more prone to cracking or fatigue failure under repeated loading. To avoid this, many standards (like ISO metric or Unified threads) specify a slight radius or flat at the root rather than a sharp V-shape.

In external threads (such as those on a bolt), the thread root is the cut-out portion between the thread ridges. In internal threads (such as those inside a nut), the root is the corresponding groove inside. Together with the crest (the top of the thread) and the flanks (the angled sides of the thread), the root helps define the overall thread profile.

Threaded Rod

Threaded Rods, similar to studs, are three feet in length or longer. The rods can be threaded on each side or along their complete length. They are designed for tension applications and can be found in warehouse buildings. Earnest’s rods are made from carbon steel for strength and durability.

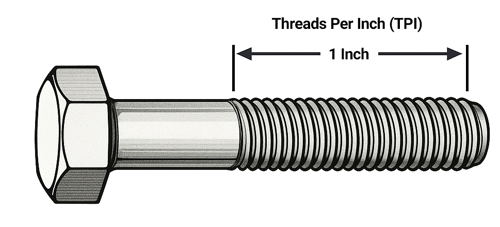

Threads Per Inch (TPI)

Threads per inch (TPI) is a measurement used to describe the density of threads on a screw, bolt, or nut in the imperial (inch-based) system. It indicates how many threads are present in one inch of length along the fastener’s shank.

For example, if a screw has 20 threads per inch, that means you would count 20 complete thread peaks along a one-inch segment of the fastener. A higher TPI means finer threads (closer together), while a lower TPI means coarser threads (fewer per inch and deeper).

TPI is part of the Unified Thread Standard (UTS), which defines thread series such as:

- UNC (Unified National Coarse): Fewer threads per inch; stronger, faster to assemble, and less likely to strip—commonly used in general applications.

- UNF (Unified National Fine): More threads per inch; provides better tension control, greater holding strength in thin materials, and more resistance to vibration.

- UNEF (Unified National Extra Fine): Very high TPI, used for precision instruments or thin-walled components.

For example:

- A ¼-20 UNC bolt has a ¼-inch major diameter and 20 threads per inch (coarse).

- A ¼-28 UNF bolt has the same diameter but 28 threads per inch (fine).

In contrast, the metric system expresses thread density as the pitch, which is the distance between adjacent threads, measured in millimeters (e.g., M6 × 1.0 has a 1.0 mm thread pitch).

Through Hardened

A heat treatment process where the entire fastener, from the surface to the core, is hardened to achieve uniform strength and hardness throughout the material. This results in fasteners with consistent mechanical properties and improved wear resistance.

Thumb Nut

A thumb nut is a specialized fastener designed for easy, tool-free installation and removal by hand. It is most suitable for applications that require quick and frequent adjustment or disassembly. Its defining feature is a head that provides a solid grip for the thumb and fingers, allowing the user to tighten or loosen it with manual force alone, which also reduces the risk of overtightening and potential damage.

The most common types of thumb nuts include the knurled and winged styles. Knurled nuts feature a rounded head with a textured, ridged, or diamond-shaped pattern that is easy to grip, even with oily or wet hands. Wing nuts, on the other hand, have two large "wings" that extend from the head, offering increased leverage for tightening. Both designs serve the same purpose: providing a reliable, yet easily manipulated, fastening solution.

Thumb nuts are used in a variety of settings, particularly in non-structural assemblies where components need to be frequently accessed or repositioned. Common applications include securing panels and covers on electronic devices, adjusting equipment in photography and audio-visual setups, assembling furniture or jigs, and in marine environments where their corrosion resistance and simple operation are advantageous.

Tie-Rod/Ball-Joint Taper Reamer

A tie-rod/ball-joint taper reamer is a precision reamer with a conical cutting profile used to cut or restore the tapered seat that accepts the stud of a tie-rod end or ball-joint. Steering and suspension studs are not straight; they are tapered so the stud wedges into the mating hole (in a knuckle, control arm, pitman/idler arm, steering arm, etc.) and locks by friction over a large contact area. The taper reamer reproduces that exact cone so the stud seats full-contact, won’t rock, and won’t pull through.

Unlike an alignment/bridge reamer (which finishes a straight round hole), a taper reamer removes material in a controlled cone. It’s commonly made from HSS with straight or spiral flutes and a straight or hex shank for use in a drill press or low-speed hand drill.

Common automotive tapers. Many North-American steering components use 1-1/2 in per foot taper (≈7.15° included), while some platforms and aftermarket parts use 2 in per foot (≈9.5° included) or other proprietary angles. Because the angle matters, you always match the reamer to the component spec (or measure the stud) before cutting.

Best practice. Ream from the side the stud enters, keep the tool square, use cutting oil and low RPM, and remove the minimum material—test-fit frequently. If a lot of material would need to come out, reconsider the joint design or use the correct component rather than forcing a mismatch; an incorrect taper is a safety risk in steering/suspension work.

Timberjack Premium Wood Screws

Timberjack timber screws speed installation, enter wood smoother and hold stronger than the leading timber screw. The special "U" shaped thread locks-in at the finish, reducing pull outs by 200%. Bonding timbers together stronger and reducing expensive call backs.

Tin (Sn)

Tin is a soft, silvery-white metal with the chemical symbol Sn (from the Latin stannum) and atomic number 50. It belongs to the post-transition metals group in the periodic table and is known for its malleability, corrosion resistance, and low melting point (231.9°C or 449.4°F). Tin has been used by humans for thousands of years, most notably as one of the key ingredients in bronze—an alloy of copper and tin that marked a major technological advance in ancient civilization.

In its pure form, tin is relatively weak and soft, which makes it easy to bend, roll, or shape. It has a bright metallic luster and produces a distinctive “tin cry” sound when bent, caused by the movement of its crystal structure. One of its most notable characteristics is its resistance to corrosion. When exposed to air, tin forms a thin, stable oxide layer that protects the underlying metal from further oxidation—this property makes it ideal for coating other metals such as steel or copper.

The most common modern use of tin is in tin plating, where it serves as a protective coating for steel cans and containers, preventing rust and oxidation—this is why we call them “tin cans,” even though the bulk of the can is actually steel. Tin is also used in soldering, where alloys of tin and lead (or tin and silver in lead-free versions) join electrical and plumbing components.

Another major application is in bronze (Cu + Sn), pewter (Sn + Sb + Cu), and bearing metals where tin improves wear resistance and lubrication. In electronics, tin oxide and indium tin oxide (ITO) are used in transparent conductive coatings for touchscreens, solar panels, and displays.

Tin can exist in two main allotropes:

- White tin (β-tin): The metallic, stable form at room temperature.

- Gray tin (α-tin): A brittle, nonmetallic form that appears below 13.2°C (55.8°F). The transition from white to gray tin is known as “tin pest”, which can cause old tin objects to crumble in cold conditions.

Tin is primarily extracted from the mineral cassiterite (SnO₂), found in regions such as China, Indonesia, Peru, Bolivia, and the Democratic Republic of Congo.

Tinnerman Nut

A Tinnerman nut, also widely known as a speed nut or Tinnerman clip, is a specialized, self-locking fastener made from stamped sheet metal. The term "Tinnerman" originated as a brand name that became a common name for this type of fastener due to its popularity. Unlike traditional nuts that require a tool to be held in place, a Tinnerman nut is designed to be easily clipped onto the edge of a panel or a stud. This design makes it a cost-effective and efficient solution for high-volume manufacturing processes.

When a screw is driven into the Tinnerman nut, the nut's spring-steel prongs are forced apart, creating continuous spring tension that grips the screw threads firmly. This unique self-locking mechanism provides excellent resistance to vibration and helps prevent the screw from loosening. Tinnerman nuts are frequently used in industries such as automotive, appliance manufacturing, and electronics to secure panels and components quickly and reliably in applications where access to the back of the material is limited.

Titanium (Ti)

Titanium is a strong, lightweight, and corrosion-resistant metallic element with the chemical symbol Ti and atomic number 22. It’s a transition metal known for its exceptional combination of high strength-to-weight ratio, biocompatibility, and resistance to extreme environments—making it one of the most valuable structural materials in modern engineering, aerospace, and medical industries.

In appearance, titanium is a lustrous silver-gray metal that is both tough and ductile. It has a melting point of 1,668°C (3,034°F) and a density about 45% lower than steel but nearly as strong. This makes it ideal for applications where both strength and weight reduction are critical, such as aircraft components, jet engines, spacecraft structures, and high-performance automotive parts.

One of titanium’s most remarkable properties is its corrosion resistance. When exposed to air or moisture, it forms a thin, tightly bonded layer of titanium dioxide (TiO₂) on its surface. This oxide film acts as a self-healing barrier against oxidation, saltwater, acids, and most chemicals. As a result, titanium is widely used in marine environments, chemical processing equipment, and medical implants where other metals would corrode.

Titanium’s biocompatibility—meaning it doesn’t react with or harm human tissue—makes it an essential material for surgical implants, prosthetics, dental hardware, and joint replacements. It integrates naturally with bone through a process called osseointegration, providing long-term stability and strength.

In metallurgy, titanium is often alloyed with elements such as aluminum, vanadium, molybdenum, and tin to create titanium alloys (like Ti-6Al-4V), which offer even higher strength, fatigue resistance, and heat tolerance. These alloys are used extensively in aerospace structures, turbine blades, performance bicycles, and high-end fasteners.

Titanium is extracted primarily from ilmenite (FeTiO₃) and rutile (TiO₂) ores, often through the Kroll process, which reduces titanium tetrachloride (TiCl₄) using magnesium to produce metallic titanium. Major producers include China, Japan, Russia, and the United States.

Titanium Carbide (TiC)

Titanium carbide (TiC) is a hard, refractory ceramic compound formed from titanium and carbon. It belongs to the family of transition metal carbides and is known for its extreme hardness, high melting point, and resistance to wear and corrosion. These properties make TiC an important material in industries that require durable, heat-resistant components such as cutting tools, coatings, and high-performance composites.

The material has a crystalline structure similar to sodium chloride, where carbon atoms fit into the spaces between titanium atoms. This arrangement produces very strong atomic bonds, which give TiC a hardness of about 9–9.5 on the Mohs scale. It also has an exceptionally high melting point of around 3,160 °C (5,720 °F). Titanium carbide is highly resistant to oxidation and chemical attack even at elevated temperatures. Its density, approximately 4.9 g/cm³, makes it heavier than boron carbide but still lighter than tungsten carbide, giving it a useful balance of hardness and weight.

Titanium carbide is produced by reacting titanium dioxide (TiO₂) with carbon, usually graphite, at extremely high temperatures in an inert or reducing atmosphere. The resulting TiC can be manufactured as a powder and then sintered into solid shapes, or it can be deposited as a thin coating using methods such as chemical vapor deposition (CVD) or physical vapor deposition (PVD). These different production techniques make it possible to use TiC both as a bulk material and as a surface treatment.

The applications of TiC are diverse. It is widely used in cutting tools, often combined with tungsten carbide (WC) and cobalt, to improve wear resistance and reduce tool chipping. As a protective coating, TiC is applied to tool surfaces and machine parts to extend their service life and enhance hardness. In abrasive applications, it is incorporated into grinding wheels and wear parts that must withstand high friction. In aerospace and defense industries, TiC is valued for its ability to maintain stability and strength at extremely high temperatures. It is also used in ceramics and composite materials to enhance toughness, hardness, and resistance to wear.

Titanium carbide provides many advantages, including extreme hardness, high wear resistance, excellent thermal stability, and strong resistance to corrosion and chemical attack. It significantly improves the durability and performance of cutting tools and industrial components, especially when combined with other carbides. However, it also has limitations. Like many ceramics, it is brittle and can crack under shock or impact loads. It is also more expensive to produce and machine than conventional metals. For these reasons, TiC is most often used in coatings or composites rather than as a standalone structural material.

Titanium dioxide (TiO₂)

Titanium dioxide (chemical formula TiO₂) is a white, inorganic compound made from the element titanium and oxygen. It is one of the whitest and brightest substances known, valued for its exceptional opacity, brightness, and UV resistance. Titanium dioxide occurs naturally in minerals such as rutile, anatase, and brookite, and it is extensively refined and processed for industrial use.

The compound’s primary function is as a white pigment and opacifier, meaning it reflects and scatters light extremely efficiently. This makes it indispensable in products like paints, coatings, plastics, papers, ceramics, rubber, inks, fibers, cosmetics, and food. In fact, titanium dioxide is the most widely used white pigment in the world, often labeled as “Titanium White” or Pigment White 6. Its chemical stability and non-reactivity allow it to retain color brilliance and opacity even in harsh environments, and it does not yellow or degrade over time.

Beyond its use as a pigment, titanium dioxide also has important photocatalytic and UV-protective properties. In sunscreens, it acts as a physical UV blocker, reflecting and scattering ultraviolet light to protect skin from sun damage. In photocatalysis, TiO₂ is used in self-cleaning coatings, air purifiers, and antimicrobial surfaces—when exposed to UV light, it generates reactive oxygen species that break down organic pollutants and kill bacteria.

There are two main crystalline forms used industrially: rutile and anatase. Rutile TiO₂ has a higher refractive index and greater stability, making it ideal for paints and coatings that require high opacity and durability. Anatase TiO₂, on the other hand, has superior photocatalytic activity and is preferred for environmental and catalytic applications.

Titanium dioxide is produced from titanium-bearing ores such as ilmenite (FeTiO₃) and rutile (TiO₂) through one of two methods: the sulfate process, which uses sulfuric acid, or the chloride process, which involves titanium tetrachloride (TiCl₄) and is cleaner and more efficient.

Toggle Bolt

A toggle bolt is a type of heavy-duty wall anchor designed for securing objects to hollow walls—such as drywall, plaster, or hollow concrete block—where a standard screw or anchor would not have enough holding power. It’s one of the strongest fasteners available for hollow wall applications.

A toggle bolt consists of two main parts: a machine screw and a spring-loaded toggle wing. The toggle wing is a metal mechanism that folds inward so it can fit through a drilled hole in the wall. Once it passes through to the other side, the wings automatically spring open, creating a wide, strong bearing surface behind the wall. As the screw is tightened, the wings pull tight against the back of the wall, distributing the load over a larger area and securely clamping the object in place.

This design makes toggle bolts ideal for hanging shelves, heavy mirrors, light fixtures, cabinets, and other objects that require strong support. They come in various sizes—larger wings and longer screws offer greater load-bearing capacity.

Toggle bolts are typically made from zinc-plated steel or stainless steel, and they are prized for their reliability in hollow materials. However, one drawback is that once installed, the toggle wings usually cannot be removed without losing them inside the wall, since they stay behind the surface after the screw is removed.

Toggle Wing Nut

A toggle wing nut, also known as a toggle bolt wing nut or simply a toggle wing, is a spring-loaded fastening component used in combination with a machine screw or bolt to anchor objects to hollow walls such as drywall, plaster, or ceilings.

The toggle wing nut consists of a pair of hinged metal “wings” that fold inward to pass through a pre-drilled hole. Once inside the wall cavity, the wings spring open automatically, creating a wide bearing surface on the inside of the wall. As the screw or bolt is tightened, the wings pull tight against the back of the wall, securely clamping the attached fixture in place.

This design distributes the load over a larger area, making toggle wing nuts ideal for medium to heavy loads where standard anchors or wall plugs might fail. They are commonly used for mounting shelves, lighting fixtures, brackets, mirrors, and ceiling hooks.

Typically made of zinc-plated or stainless steel, toggle wing nuts are reusable (if the screw can be removed carefully) and come in various sizes to fit different wall thicknesses and load requirements.

AKA: Toggle Bolt Wing Nut, Toggle Wing

Tommy Bar

A tommy bar is a metal bar used as a lever to provide extra torque when tightening or loosening fasteners, such as nuts, bolts, and screws. It is sometimes called a T-bar due to its common T-shaped handle, which allows for a comfortable, two-handed grip to apply greater leverage. Tommy bars are also used to operate chucks and tool holders on machinery, such as lathes and milling machines. They are particularly useful for reaching fasteners in tight or confined spaces where a conventional wrench might not fit or be maneuverable.

There are several variations of tommy bars to suit different needs. A Solid T-Handle has a fixed, perpendicular handle for a sturdy, high-torque grip. A Sliding T-Handle has a crosspiece that can be moved along the bar's length to adjust the leverage point. For variable torque requirements and reaching difficult spots, a Telescopic Tommy Bar can be extended or shortened. For greater efficiency during assembly or maintenance, a Ratchet Tommy Bar incorporates a ratchet mechanism to tighten or loosen without repositioning the tool.

While a tommy bar provides controlled force for fasteners, it is different from a breaker bar. A breaker bar is a longer, non-ratcheting tool designed for maximum leverage to "break loose" extremely tight or rusted bolts. A tommy bar is used for more controlled, steady turning, whereas a breaker bar is typically used to apply a high initial twist. By applying controlled, precise force, tommy bars prevent damage and ensure secure, proper fastening.

Torque

Torque for fasteners is the rotational force applied to tighten a bolt, screw, or nut so that it generates the proper amount of clamping force between the joined parts. It is one of the most important concepts in fastening because if too little torque is applied, the joint may loosen and vibrate apart, but if too much torque is applied, the fastener can be overstressed, the threads may strip, the joint material may be crushed, or the fastener may even break.

Torque is defined as the measure of a turning or twisting force applied around an axis. In the context of fasteners, it is measured in units such as Newton-meters (N·m), inch-pounds (in-lb), or foot-pounds (ft-lb). Specialized tools like torque wrenches, torque screwdrivers, and automated assembly machines are used to apply and verify the correct torque so that fasteners are tightened properly and consistently.

The main purpose of applying torque is to achieve the proper preload, which is the clamping force created when a fastener is tightened. Preload keeps the joined parts in firm contact, helps resist separation under service loads, and evenly distributes stresses throughout the joint. Correct torque application prevents fasteners from loosening under vibration, protects against separation of the joint, avoids overstressing and yielding of the fastener, and ensures that gaskets or seals are evenly compressed where sealing is necessary.

Several factors affect the amount of torque required for a fastener. Thread size and pitch play a role, since larger and coarser threads generally need higher torque. The material and grade of the fastener also matter, as stronger alloys are designed to handle greater torque levels. Lubrication can significantly reduce friction, meaning less torque is needed to achieve the same preload compared to dry threads. Surface finishes or coatings such as zinc or phosphate also change frictional characteristics, while the type of joint material influences how much torque can be applied before deformation occurs, especially in softer materials.

Torque-controlled fasteners are used in many fields. In automotive and aerospace applications, precise torque is essential for components like cylinder heads, wheel lugs, and aircraft structures. In industrial machinery, torque ensures that bolts in rotating equipment remain tight despite vibration. In construction, torque is used to secure structural fasteners in frameworks or bridges. In electronics and precision assemblies, small screws require very specific torque levels to prevent stripping.

Applying the correct torque provides key advantages. It ensures safety and reliability in assemblies, increases the lifespan of fasteners by preventing overstressing, and maintains the performance of gaskets, seals, and structural joints. However, torque does have limitations. It does not directly measure clamping force, but instead serves as an indirect method since much of the applied torque is lost to friction. Variations in lubrication, thread condition, or surface material can cause significant differences in preload even when the same torque is applied. For highly critical applications, more precise methods such as torque-angle tightening or the use of tension control bolts are employed to improve accuracy and consistency.

Torque Resistance

Torque resistance is a measure of a component or fastener’s ability to resist rotational movement when a twisting or turning force (torque) is applied. In simple terms, it describes how well a part can stay locked in place and prevent spinning within its mounting material when subjected to torque during assembly or service.

In the context of mechanical fasteners—especially self-clinching nuts, studs, threaded inserts, and press-fit components—torque resistance ensures that the fastener does not rotate when a mating screw or bolt is tightened or loosened. For instance, when you tighten a screw into a self-clinching nut embedded in sheet metal, the nut must remain stationary to allow proper tightening. Its torque resistance is what prevents it from spinning freely inside the sheet.

The resistance to rotation usually comes from mechanical interlocking or surface friction between the fastener and the surrounding material. In self-clinching fasteners, this is achieved by knurls, serrations, ribs, or undercut grooves on the fastener’s body that grip the surrounding metal when pressed in under high pressure. The sheet metal cold-flows into these features during installation, creating a permanent interlock. This interlock provides both axial retention (resisting pull-out) and torque resistance (resisting spin).

Torque resistance is often tested by applying a rotational load to the fastener until it begins to slip or rotate within its host material. The measured value (typically expressed in inch-pounds or Newton-meters) represents the fastener’s torque-out strength. This property is especially important in applications subject to vibration, dynamic loads, or frequent assembly/disassembly, such as in automotive panels, aerospace structures, and electronic housings.

Torque resistance differs from axial retention, though both work together to keep a fastener secure. Axial retention prevents the fastener from being pulled straight out, while torque resistance prevents it from twisting or turning out of position.

Torque Sensor

A torque sensor is a device that measures the rotational force (torque) applied to a shaft, bolt, motor, or mechanical system. Torque is a measure of how much a force causes something to rotate and is typically expressed in Newton-meters (N·m), pound-feet (ft-lb), or inch-pounds (in-lb). Torque sensors convert that mechanical twisting force into an electrical signal that can be read by instruments, test equipment, or control systems.

Torque sensors work by detecting strain caused by twisting. Inside the sensor, a shaft or flexing element slightly deforms when torque is applied. That deformation is measured using one of several technologies:

- Strain gauge sensors use bonded strain gauges in a Wheatstone bridge to detect microscopic stretching under load.

- Magnetoelastic sensors detect changes in magnetic permeability as a shaft twists.

- Optical and capacitive sensors measure displacement or angle between components.

- Reaction torque sensors measure force without requiring rotation, often mounted in static fixtures.

- Rotary torque sensors measure torque on spinning shafts using wireless telemetry or slip rings.

Torque sensors are critical in engine testing, electric motors, robotics, fastener testing, wind turbine drives, industrial automation, and quality control for bolted joints. For example, when tightening fasteners, a torque sensor can verify applied torque to ensure joints are neither under-tightened (risking loosening) nor over-tightened (risking bolt yield or fracture).

Torque Washer

A torque washer is a washer specifically designed with locking or anti-rotation features that help prevent nuts, bolts, or screws from loosening under torque, vibration, or heavy load. Unlike a standard flat washer, which serves only to spread load, a torque washer actively resists movement of the fastener once tightened, making it an important component in assemblies where reliability is critical.

Torque washers are generally manufactured from hardened steel, stainless steel, or other strong alloys to endure repeated tightening and heavy stresses. Their distinguishing characteristic is the geometry of the inner or outer surface, which interacts with the fastener or the clamped material to resist rotation. Designs vary widely. Some have serrated or toothed faces that grip against the fastener head or the surface of the joint. Others feature square or rectangular holes designed to fit over carriage bolt shoulders to prevent turning. Certain types include external protrusions or tangs that bite into the base material or slot into pre-made grooves for added stability. There are also specialized patterns tailored for unique fastener types and applications.

The primary function of a torque washer is to maintain consistent clamping force in joints subject to torque and vibration. By resisting rotation of the fastener head or nut, the washer ensures that preload—the clamping force generated during tightening—is not lost. This consistent preload extends joint life, prevents fastener loosening, and enhances safety, particularly in high-stress or dynamic environments.

Torque washers see wide use in many industries. In automotive and aerospace applications, they are used in assemblies exposed to continuous vibration and cyclic loading. In construction, they are commonly found in structural steel joints, heavy machinery, and other bolted connections. In electrical and mechanical systems, they help secure equipment subject to fluctuating forces. Torque washers are also frequently paired with carriage bolts, where their square-hole design keeps the bolt from spinning during tightening in wood or metal framing.

These washers offer several advantages. They effectively prevent loosening under torque and vibration, preserve joint integrity and safety, reduce the need for adhesives or secondary locking methods, and are often reusable depending on material and design. However, they also come with limitations. Torque washers tend to be more expensive than standard flat washers, and their biting edges can damage softer materials. In addition, they may not be suitable for applications where appearance is important, since serrated or toothed surfaces can leave visible marks on the joint material.

Torque-Angle Tightening

Torque-angle tightening is a fastening method that uses a two-step process to achieve a precise and consistent clamping force. First, a specified torque is applied to seat the fastener and eliminate any clearance. Then, the fastener is rotated further by a defined angle of rotation. This process produces a more accurate preload compared to torque-only tightening, because it minimizes the effect of friction between the threads and under the bolt head.

In practice, torque-angle tightening begins with a torque wrench or specialized tool applying a snug torque, which ensures the fastener is properly seated. Once this initial torque is reached, the fastener is rotated an additional specified angle, such as 90°, 120°, or 180°. The measured angle corresponds to a predictable elongation of the fastener, and this elongation directly generates bolt tension, which in turn creates the clamping force required for the joint.

The main purpose of torque-angle tightening is to achieve consistent preload in bolted joints. Friction under the head and in the threads can account for 80–90% of applied torque, meaning torque alone often results in significant variation in clamping force. By focusing on the fastener’s elongation instead, torque-angle tightening controls the actual stretch of the bolt rather than relying solely on torque readings, providing more reliable and uniform results.

This method is widely used in critical applications. In automotive engines, it is common for cylinder head bolts, main bearing caps, and connecting rod bolts. Aerospace and heavy machinery industries also rely on torque-angle tightening to ensure that joints subjected to heavy loads and vibration maintain consistent preload. It is also applied in structural and high-load assemblies where precise and repeatable bolt tension is essential.

The advantages of torque-angle tightening include its ability to deliver highly consistent preload regardless of friction variations, a reduced risk of both under-tightening and over-tightening, and improved joint reliability in demanding applications. It is especially effective with torque-to-yield (TTY) bolts, which are designed to be tightened beyond their elastic limit to achieve maximum clamping force.

However, the method does have limitations. It requires specialized equipment to accurately measure the angle of rotation, making it more time-consuming than simple torque tightening. Torque-to-yield bolts used with this method are also single-use fasteners and must be replaced once removed. Additionally, torque-angle tightening is not always necessary for non-critical or low-load assemblies, where simpler torque methods may be sufficient.

Torque-to-Yield Bolt (TTY)

A Torque-to-Yield (TTY) bolt is a fastener designed to be tightened beyond its elastic limit into the plastic range, meaning it permanently stretches slightly during installation. Instead of relying on torque alone, these bolts are tightened in two steps: first to a specified torque value, then by a set angle of rotation. This method ensures a highly accurate and uniform clamping force, making TTY bolts especially useful in critical applications such as engine cylinder heads, main bearings, and connecting rods, where consistent pressure is vital to prevent leaks or failures.

Because they are stretched past their yield point, TTY bolts cannot be safely reused—once removed, they must be replaced. While more costly and requiring precise torque-angle tools, their ability to deliver consistent load distribution makes them a preferred choice in demanding environments where reliability is essential.

AKA: Stretch Bolt

Torsional Deformation

Torsional deformation is the twisting or rotational displacement that occurs in a structural member—such as a shaft, rod, or beam—when it is subjected to a torque or twisting moment about its longitudinal axis. Unlike bending, which produces curvature, torsion produces an angular twist along the length of the member. This deformation arises because the applied torque generates shear stresses inside the material, causing each cross-section to rotate relative to its neighboring sections.

The extent of torsional deformation depends on several factors: the magnitude of the applied torque, the length of the shaft, the material’s rigidity, and the geometry of the cross-section. For a uniform circular shaft, the angle of twist is determined by the relationship θ = (T × L) / (G × J), where T is the torque, L is the length of the shaft, G is the shear modulus of the material, and J is the polar moment of inertia of the cross-section. This formula highlights that stiffer materials with higher shear modulus and shapes with larger polar moment of inertia (such as thick or hollow tubes) resist torsional deformation more effectively.

In practice, torsional deformation is important in mechanical and structural design because excessive twisting can cause misalignment, vibration, fatigue, or even failure. For example, in drive shafts, fasteners, and transmission systems, engineers must carefully account for torsional deformation to ensure efficiency, durability, and safety. It is often controlled by selecting proper materials, optimizing geometry, or limiting the applied torque to safe operating ranges.

Torx Bit

A Torx bit is a precision driver bit designed to fit and turn Torx screws, which have a six-point, star-shaped recess in their heads. The Torx bit’s distinctive star-shaped tip allows it to engage securely with the screw, providing superior torque transfer and reducing the risk of slippage or damage compared to flathead or Phillips drivers.

Each Torx bit is labeled with a “T” size designation (such as T10, T15, T25, or T40), which corresponds to the size of the Torx screw it fits. The bits are available in standard, tamper-resistant (security), and impact-rated versions. The tamper-resistant type includes a hole in the center to accommodate the security pin found on tamper-proof Torx screws.

Torx bits are typically made from hardened tool steel or impact-rated alloys, and they are commonly used with screwdrivers, ratchets, or power drills for applications in automotive, electronics, aerospace, manufacturing, and home repair.

Torx Screw

A Torx screw is a type of screw characterized by a six-point, star-shaped recess in its head, designed to be used with a matching Torx driver or Torx bit. The design was developed by Camcar Textron in 1967 to provide a more efficient and secure connection between the tool and the fastener.

The unique star-shaped pattern allows for better torque transfer than traditional Phillips or slotted screws because it distributes the applied force over a larger surface area. This design minimizes the risk of cam-out (when a screwdriver slips out of the head under torque) and reduces wear on both the screw and the tool.

Torx screws come in various sizes—identified by a “T” number (for example, T10, T20, T25)—which correspond to the size of the recess. They are commonly found in automotive, aerospace, electronics, machinery, and precision equipment applications where consistent torque and durability are important.

Some versions, called Tamper-Resistant Torx or Security Torx, include a small pin in the center of the recess to prevent removal with standard Torx bits, providing additional protection against unauthorized access.

Toughness

A fastener's ability to absorb energy and deform (change shape) significantly before fracturing or breaking. A tough material effectively resists cracks from spreading and can withstand sudden impacts or shock loads without sudden, complete failure. This property is a crucial balance between a material's strength and its ductility.

Tower Crane Bolt

A tower crane bolt is a high-strength structural fastener specifically designed to connect and secure the major components of a tower crane, such as the mast sections, jib, slewing unit, and base. Because tower cranes operate under enormous loads and dynamic stresses, these bolts play a critical safety role—maintaining the crane’s stability, alignment, and structural integrity even under heavy lifting, wind, and vibration.

Tower crane bolts are typically made from high-grade alloy steels (such as 10.9 or 12.9 class according to ISO standards) and are heat-treated to achieve exceptional tensile and yield strength. They are engineered for fatigue resistance since cranes experience continuous cyclic loading during operation. Bolts are usually torqued or tensioned to precise specifications to ensure consistent clamping force and to prevent loosening under vibration.

Common types include:

Mast section bolts – used to connect the vertical tower segments.

Turntable bolts – secure the slewing unit or rotation mechanism.

Jib and counter-jib bolts – connect the working arm and counterweight arm.

Anchor bolts – fix the crane’s base to the foundation or mounting frame.

Most tower crane bolts are galvanized or coated to protect against corrosion from outdoor exposure, and many are subject to inspection, torque verification, and periodic replacement per manufacturer and safety regulations.

Track Bolt

A track bolt is a heavy-duty fastener specifically designed to secure railway tracks (rails) to the rail chairs, baseplates, or sleepers (ties) in railroad construction. These bolts play a critical role in maintaining track alignment, stability, and safety by ensuring that the rails remain firmly fastened under the extreme loads and vibrations caused by passing trains.

Track bolts typically feature a square or oval neck just beneath the head, which fits into a matching recess in the rail or plate. This design prevents the bolt from turning when the nut is tightened, allowing for secure and efficient installation. The head shape can vary depending on the rail system—it’s often round, oval, or mushroom-shaped, and sometimes includes markings for identification and orientation.

They are made from high-tensile carbon steel or alloy steel and often undergo heat treatment and galvanization or black oxide finishing for corrosion resistance and durability in harsh outdoor environments.

Track bolts are used in railroad systems, mining tracks, cranes, heavy machinery rails, and industrial transport systems—essentially any setup where metal rails guide and support moving loads.

Track Shoe Bolt

Track shoe bolts are specialized fasteners used specifically to attach the track shoes, or pads, to the track chain of crawler-type machinery such as bulldozers and excavators. These bolts are designed to withstand heavy impact, vibration, and wear from constant ground contact. They typically feature a domed or oval head, and may include locking features like a ribbed neck or fine threads to prevent loosening under high stress. Their strength and design make them critical for maintaining the integrity and performance of the track system.

Treehouse Lag Bolt

A treehouse lag bolt—often referred to as a Treehouse Attachment Bolt (TAB) in professional builds—is a long, heavy-duty structural lag bolt specifically engineered to support the load of a treehouse while minimizing damage to the tree. Unlike standard lag bolts used in carpentry, treehouse lag bolts are oversized, typically 6"–12"+ in length, 1"–1.5" in diameter, and designed to anchor deeply into the tree’s load-bearing tissue. They are usually made from high-strength steel and feature stepped or shouldered profiles that help transfer load efficiently.

The defining feature of a treehouse lag bolt is its shear-support design. Instead of simply pulling two materials together like a normal lag screw, TABs support large vertical and lateral loads by acting as a structural cantilever. The load rests on a large shoulder or perch rather than relying only on thread strength. This allows the treehouse platform to sit on a bracket or pipe bracket mounted to the bolt, distributing weight without crushing bark or restricting growth.

Because trees expand over time, treehouse lag bolts are designed to allow for tree growth and movement, often working in conjunction with brackets that slide, pivot, or compensate for sway. High-end TABs can support 1,000–5,000+ lbs per bolt, depending on bolt size, wood species, installation depth, and bracket design.

AKA: Treehouse Attachment Bolt (TAB)

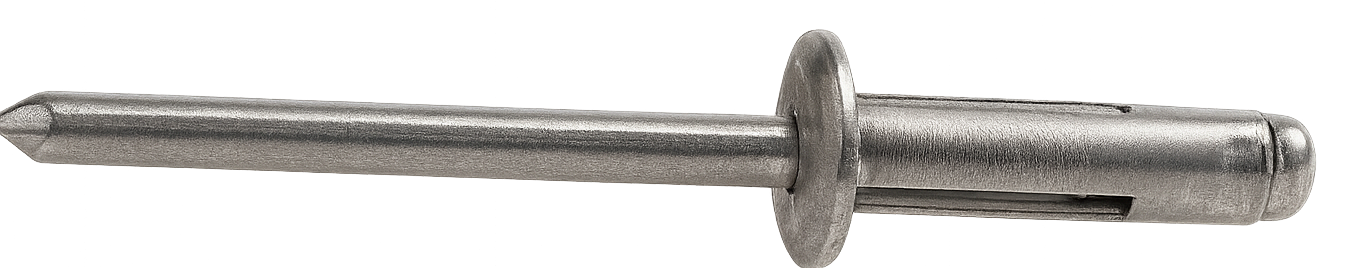

Tri-Fold Rivet

A tri-fold rivet (sometimes called a tri-fold blind rivet) is a type of specialty blind rivet designed to provide strong holding power in soft, thin, or brittle materials such as plastics, fiberglass, laminates, or thin sheet metals.

When the rivet is installed, the mandrel pulls the body of the rivet back into itself, causing the sleeve to split into three equal sections. These three legs then fold outward in a triangular pattern on the blind side of the material. This “tri-fold” formation spreads the load across a larger surface area than a standard blind rivet, which prevents pull-through, reduces stress on the material, and increases joint strength.

Because of this unique expansion pattern, tri-fold rivets are often used in applications like automotive interiors, fiberglass panels, marine equipment, and lightweight assemblies where materials cannot withstand the concentrated force of a traditional rivet head. They’re particularly useful when fastening thin or soft substrates to metal components, as the three-point anchoring provides both strength and resistance to vibration loosening.

Tri-Groove Nut

A tri-groove nut is a tamper-resistant security nut with a smooth, conical (or domed) outer shape and three recessed grooves around the sides of the cone. Instead of using flats for a wrench, it’s designed so you cannot grip it with standard tools (wrenches, pliers, sockets). To install or remove it, you need a special tri-groove socket that matches the three-lobed recess.

In use, a tri-groove nut is typically tightened once and then effectively becomes permanent or semi-permanent—ideal anywhere you want to deter theft, vandalism, or tampering: public benches and railings, restroom partitions, security grates, signs, playground equipment, access panels, and exposed hardware on machinery or enclosures. They’re often made from stainless steel or zinc-plated steel for corrosion resistance, and are part of the broader family of security fasteners (alongside one-way screws, pin-in Torx®, etc.) that protect fixtures and equipment in public or high-traffic environments.

Tri-Groove Screw

A tri-groove screw is a type of tamper-resistant security fastener whose head is shaped with three curved, evenly spaced grooves instead of a standard drive like hex, Phillips, or Torx®. The tri-groove profile is smooth and sloped, with no sharp corners for common tools to grip, so it cannot be installed or removed with standard wrenches or screwdrivers. To work with it, you need a special tri-groove socket or driver that matches the three-lobed profile.