Resources

Glossary

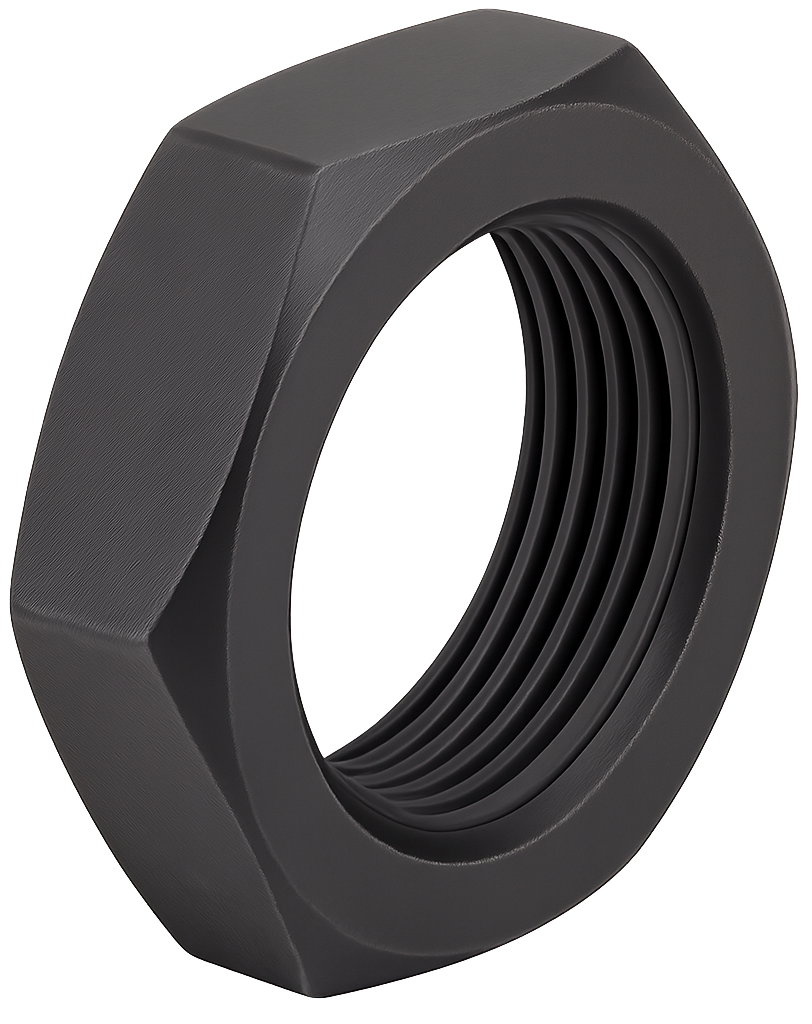

Backing Nut

A backing nut is a type of nut that works in combination with another nut to provide additional security, load distribution, or resistance to loosening in a bolted connection. It is generally installed behind or alongside the primary nut, serving as a reinforcement that helps strengthen the joint. Backing nuts are often thinner than standard hex nuts, and depending on the application or industry, they may also be referred to as jam nuts, check nuts, or locknuts.

The main function of a backing nut is to improve the stability of a threaded assembly. When it is tightened against another nut or component, the backing nut helps lock the primary nut in place and prevents it from loosening due to vibration, thermal expansion, or shifting loads. In addition to providing a locking effect, backing nuts are sometimes used to help distribute loads more evenly across clamped surfaces, which protects the threads and reduces the chance of damage to the materials being joined.

Backing nuts have distinct properties that make them effective in these roles. They are typically thinner than a standard nut, which allows for dual-nut installation without adding excessive length to the assembly. They provide a frictional locking action when tightened against another nut, making them more resistant to loosening. They are manufactured in various materials, including steel, stainless steel, and brass, with the choice often depending on the application and the material of the primary nut and bolt. Importantly, a backing nut must always match the thread pitch and diameter of the bolt or stud it is used with to ensure compatibility and proper function.

Their applications span many industries. In mechanical and structural assemblies, backing nuts are commonly used to secure primary nuts in heavy equipment, construction, and machinery where vibration or shock loading could cause fasteners to loosen. In pipe fittings and plumbing, they are used with unions and couplings to hold fittings together tightly and prevent leaks. In the automotive and aerospace industries, backing nuts are applied in assemblies that must remain secure under vibration and movement. They are also widely used in electrical and conduit systems, where they help fasten connectors or conduit fittings to enclosures or panels.

The use of backing nuts provides several advantages. They offer extra protection against loosening in high-vibration environments, extending the service life of joints by reducing the risk of failure. They also allow for easy adjustment and disassembly, which can be more practical than permanent locking methods. Finally, they are a cost-effective solution compared to more specialized locknuts or locking washers.

Although the terms backing nut, jam nut, and check nut are sometimes used interchangeably, there are distinctions. A backing nut specifically refers to its role as a backup or reinforcement to another nut. A jam nut is a thin nut used to lock a standard nut in place by tightening them together. In plumbing contexts, a backing nut is purpose-built to secure fittings, unions, or conduit. While the functions overlap, the terminology varies depending on the application and industry standards.

Backout Prevention

Backout prevention refers to the methods, features, or design elements that keep a fastener—such as a screw, bolt, or nut—from loosening and backing out of its threaded connection during service. This is critical because vibration, thermal expansion, mechanical stress, or repeated loading can cause standard fasteners to gradually rotate, lose clamping force, and ultimately lead to joint failure.

There are several approaches to achieving backout prevention. Mechanical locking features include devices such as lock washers, lock nuts, cotter pins, and safety wire. These add either resistance or physical barriers that prevent the fastener from rotating. Thread-locking compounds and coatings, such as anaerobic adhesives like Loctite® or pre-applied patches, bond threads together and create friction that resists loosening. Some specialized fastener designs incorporate serrations, prevailing torque features, or unique thread geometries that provide self-locking properties. In more demanding environments, secondary retention systems such as wire locking, tab washers, or staking are used, particularly in aerospace and automotive industries, to provide redundancy and maximum security.

Backout prevention is especially important in applications where loosening could create safety hazards, cause equipment damage, or compromise performance. This includes aerospace components, automotive assemblies, vibrating machinery, and critical infrastructure. By using backout prevention methods, engineers ensure that fastened joints remain secure, reliable, and safe throughout their service life.

Backplate

A backplate in the context of fasteners is a reinforcing plate, usually a flat piece of metal or strong composite material, that is used on the opposite side of a joint to provide extra strength and load distribution. It acts as a backing surface for bolts, screws, or rivets, preventing them from pulling through softer or thinner materials.

Backplates are especially important in assemblies where the base material alone cannot withstand the forces of the fastener. By spreading the load across a wider surface area, the backplate reduces stress and prevents localized deformation, cracking, or tearing. This is particularly useful when fastening into wood, composites, sheet metal, or plastics.

They are commonly used in structural applications, aerospace, automotive, marine, and construction industries. For example, backplates are often paired with rivets in aircraft structures to ensure joints remain secure under vibration and stress, or with bolts in marine hardware where repeated loading could otherwise damage the hull material.

Ball Lock Pin

A ball lock pin is a quick-release fastener that uses spring-loaded balls at the tip of the pin to provide secure yet easily removable fastening in mechanical assemblies. Unlike threaded bolts or standard pins, it allows for rapid insertion and removal while still offering strong holding power. Because of this, ball lock pins are widely used in aerospace, automotive, marine, tooling, and manufacturing where efficiency and repeatability are critical.

The pin’s design includes a shaft, usually stainless or alloy steel for strength and corrosion resistance, with spring-loaded balls near the tip that expand to lock into place. At the other end is a release mechanism, often a button or pull-ring, which retracts the balls when pressed. The head can vary—T-handle, L-handle, button, or ring—depending on ergonomics and application.

Their function is simple: once inserted, the balls extend outward to secure the pin, preventing accidental removal. To release, the operator presses the button or pulls the handle, retracting the balls and allowing the pin to slide out. This design provides fast, tool-free assembly and disassembly.

Ball lock pins are valued for being quick-acting, secure, and strong, with good corrosion resistance for outdoor or marine use. They come in many styles, diameters, and lengths to suit different needs. Applications range from aerospace components that require frequent removal, to motorsports for quick part changes, to marine fittings, tooling fixtures, and construction equipment.

The main advantages are time savings, tool-free operation, and reliable holding strength, even with repeated use. These qualities make ball lock pins an essential fastener wherever speed, safety, and strength must work together.

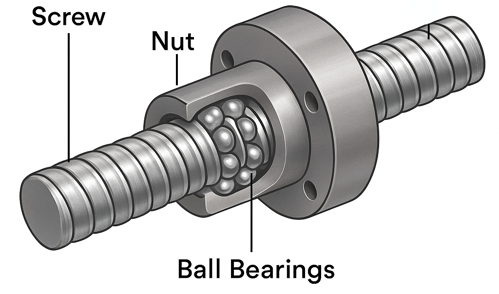

Ball Screw

A ball screw is a precision mechanical device that converts rotary motion into linear motion with high efficiency and minimal friction. It consists of a threaded shaft (the screw) and a nut that houses a series of recirculating ball bearings. As the screw rotates, the ball bearings roll between the screw’s helical grooves and the nut’s matching grooves, creating smooth movement while greatly reducing friction compared to traditional lead screws.

The rolling action of the ball bearings is what makes a ball screw distinct. Instead of sliding contact between threads, which causes wear and energy loss, the bearings roll along the grooves. This rolling motion allows ball screws to achieve efficiencies of 90% or higher, enabling them to move heavy loads precisely with relatively little torque.

Ball screws are widely used in applications that require accuracy, repeatability, and efficiency. Common uses include CNC machines, robotics, aerospace systems, medical equipment, and precision assembly machinery. They are valued for their ability to handle high loads, provide tight positional accuracy, and maintain long service life under continuous use.

In summary, a ball screw is a high-performance screw mechanism that uses rolling ball bearings between the nut and screw threads to provide smooth, efficient, and precise linear motion, making it a cornerstone of modern motion-control systems.

Ball Stud

A ball stud is a type of fastener that features a threaded shank on one end and a spherical ball head on the other. The ball end is designed to fit into a socket, allowing for pivoting and rotational movement while still maintaining a secure connection. Together with a mating socket, the ball stud forms a ball-and-socket joint.

In fastener and mechanical applications, ball studs are most commonly used where controlled movement and articulation are needed. The threaded shank secures the stud into a component, while the ball end provides a smooth pivot point. This allows connected parts to move freely within a defined range of motion while staying firmly attached.

Ball studs are widely used in automotive, aerospace, and industrial equipment. Common applications include suspension systems, steering linkages, gas springs, hood supports, and adjustable arms, where they allow flexibility and reduce stress from misalignment. They are also found in machinery and fixtures that require frequent movement without loosening the fastened connection.

In summary, a ball stud is a specialized fastener that combines a threaded base with a pivoting ball head, making it ideal for joints where strength, flexibility, and reliability are required.

Band Clamp

A band clamp is a fastening device that uses a flexible metal or plastic band tightened around an object to secure, hold, or compress it. Unlike rigid clamps, a band clamp conforms to the shape of the object, making it versatile for securing irregular, round, or large surfaces.

The clamp typically consists of a band (commonly stainless steel for strength and corrosion resistance), a tightening mechanism such as a screw or ratchet, and sometimes a housing or buckle that locks the band in place. When tightened, the band evenly distributes clamping force around the object, ensuring a secure grip without concentrated stress points.

Band clamps are widely used across industries. In automotive and mechanical applications, they secure hoses, pipes, and ducting by providing a tight seal that prevents leaks. In construction and woodworking, they are used to clamp frames, furniture, or cylindrical objects during assembly. In aerospace and marine environments, band clamps are favored for their strength, reliability, and resistance to harsh conditions.

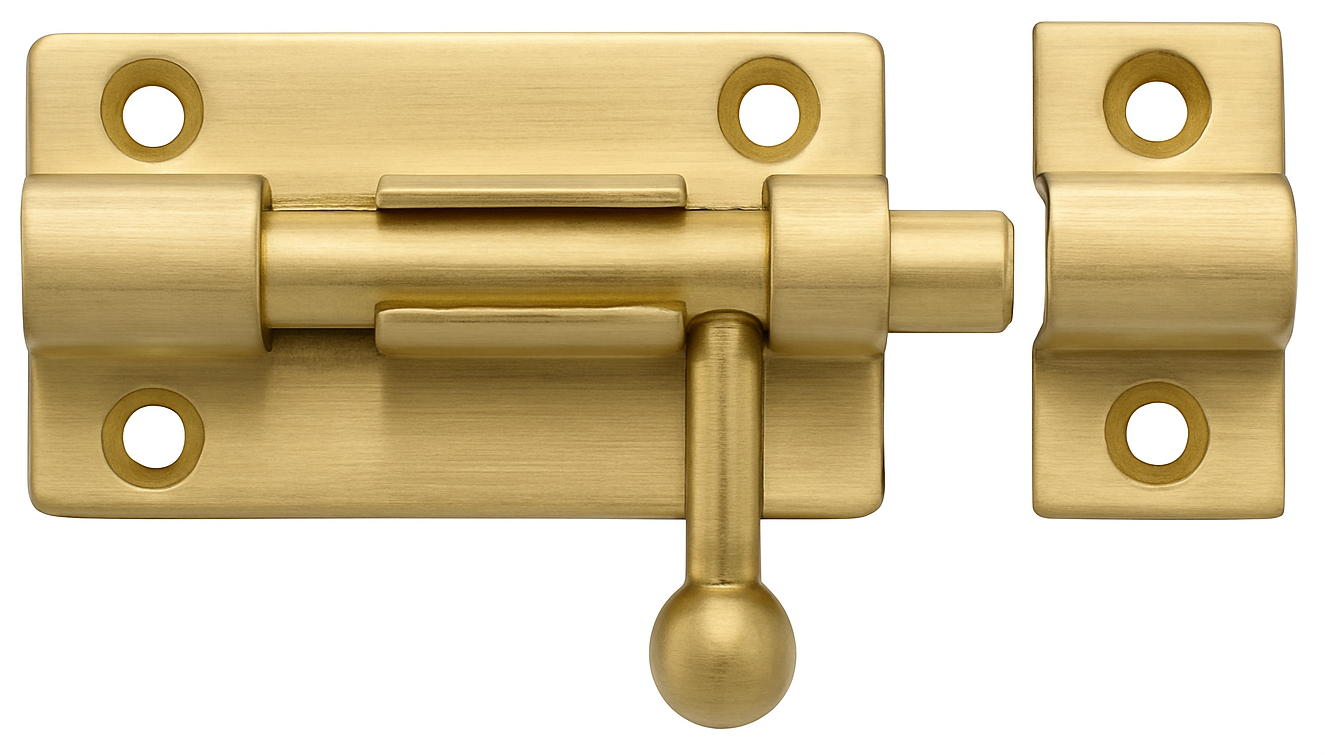

Barrel Bolt

A barrel bolt is a type of sliding bolt used for fastening doors, gates, cabinets, and similar closures. It consists of two main parts: a long cylindrical metal rod (the “barrel”) that slides into a catch or socket, and a fixed mounting plate that holds the rod in place. The barrel is operated manually by sliding it back and forth to lock or unlock the closure.

When in the locked position, the barrel extends into a corresponding socket or bracket mounted on the frame, preventing the door or panel from opening. When retracted, the bolt clears the socket, allowing the door or gate to swing freely. The design is simple, durable, and provides a straightforward way to secure closures without requiring keys or complex mechanisms.

Barrel bolts are commonly made from steel, brass, or stainless steel, and they come in a variety of sizes depending on the level of security and strength needed. They are often used in residential, commercial, and industrial applications, such as securing gates, restroom doors, storage lockers, and cabinets. Some heavy-duty versions may include padlockable features for added security.

Barrel Nut (Cross Dowel)

A barrel nut, also known as a cross dowel, is a type of fastener used to create strong right-angle connections in wood, metal, or composite assemblies. It consists of a cylindrical metal barrel with an internally threaded hole drilled through its side (the “cross” hole). A bolt is inserted into the mating piece and threaded into the barrel nut, which sits in a perpendicular hole.

Because the load is spread across the full diameter of the barrel nut rather than just the threads in wood or composite, this fastener provides a very strong and durable joint. The design allows for easy disassembly and reassembly, making it ideal for knock-down or flat-pack assemblies.

Furniture assembly (beds, cabinets, bookshelves).

Architectural joinery for secure wood-to-wood joints.

Metal framing and machinery where perpendicular bolted connections are needed.

Bauxite

Bauxite is the primary ore of aluminum—a naturally occurring rock made mainly of hydrated aluminum oxides (primarily gibbsite, boehmite, and diaspore) mixed with impurities such as iron oxides, silica, and titania. In industrial terms, bauxite is valuable because it’s the starting raw material used to produce alumina (Al₂O₃) and, ultimately, primary aluminum metal.

Why it matters in the fastener industry: bauxite sits at the very front of the supply chain for aluminum and many aluminum alloys used in fasteners (and the components fasteners assemble). Bauxite is refined into alumina (commonly via the Bayer process), and alumina is then electrolytically reduced to aluminum metal (commonly via the Hall–Héroult process). That aluminum becomes billet, bar, wire, or coil stock used to make aluminum screws, bolts, rivets, and specialty hardware, and it also influences the availability and pricing of aluminum across industrial markets.

Beyond aluminum metal production, alumina and bauxite-derived products also show up around fastener manufacturing and industrial environments as refractory materials (furnace linings), abrasives/blasting media, and other process/plant consumables. The specific mineral makeup and impurity levels of a bauxite deposit affect how it’s processed and what byproducts are generated, but in fastener terms the key takeaway is simple: bauxite → alumina → aluminum, and that chain supports a large portion of lightweight, corrosion-resistant hardware and industrial assemblies.

Bayer Process

The Bayer Process is the primary industrial method for refining bauxite ore into alumina (aluminum oxide, Al₂O₃) — the key raw material used in aluminum production. It was developed in 1888 by Karl Josef Bayer, and it remains one of the most important processes in modern metallurgy.

The process exploits the fact that aluminum-containing minerals in bauxite (mainly gibbsite, boehmite, and diaspore) are soluble in caustic soda (sodium hydroxide, NaOH) under high temperature and pressure, while most other minerals in the ore (like iron oxides and silica) are not.

Here’s how it works step by step:

1. Crushing and Grinding:

The bauxite ore is first crushed and ground into a fine powder to increase the surface area for chemical reactions.

2. Digestion (Dissolution):

The powdered bauxite is mixed with a hot, concentrated caustic soda solution under pressure (up to 200°C). The sodium hydroxide dissolves the aluminum-bearing minerals to form sodium aluminate (NaAlO₂), while impurities such as iron oxide (Fe₂O₃), silica (SiO₂), and titanium dioxide (TiO₂) remain largely insoluble.

3. Clarification (Separation):

The resulting mixture, called the slurry, is allowed to settle or is filtered to remove the insoluble residues, known as red mud—a waste product rich in iron oxide and other impurities. The clear sodium aluminate solution is then separated for further processing.

4. Precipitation:

The clear solution is cooled and seeded with fine alumina crystals, which trigger the precipitation of aluminum hydroxide [Al(OH)₃] from the sodium aluminate solution. This step reverses the earlier chemical reaction under controlled conditions.

5. Calcination (Heating):

The aluminum hydroxide is then heated in rotary kilns or fluidized bed calciners at about 1,000°C–1,200°C, driving off water and leaving behind pure alumina (Al₂O₃) — a white, powdery substance ready for aluminum smelting.

6. Smelting (via the Hall–Héroult process):

The Bayer process produces alumina, which is then used in the Hall–Héroult process to extract metallic aluminum through electrolysis.

Beam Clamp

A beam clamp is a hardware device used to securely attach rods, hangers, conduit, piping, or cable-support systems to structural beams—usually I-beams, wide-flange beams, or channels—without drilling or welding into the structure. This makes beam clamps essential in commercial, industrial, and construction environments where building integrity and code compliance require non-invasive mounting.

Structurally, a beam clamp grips the flange of the beam using a mechanical clamping action (a threaded screw, set bolt, or spring-loaded jaw). Once tightened, it provides a strong attachment point for threaded rod, bridle rings, cable trays, sprinkler lines, HVAC duct supports, lighting, or other suspended systems. Because they avoid drilling, beam clamps also make repositioning or adjusting installations much easier.

Beam clamps come in many forms, including:

- C-style clamps with a set screw for gripping beam flanges

- Spring-steel snap clamps for light-duty electrical and data cabling

- Top or bottom flange clamps depending on how the load needs to be supported

- Forged heavy-duty clamps for mechanical systems, piping, or overhead loads

- Clamps with integrated threaded holes (¼-20, ⅜-16, ½-13, etc.) for attaching rod or accessories

In industrial fastener terms, beam clamps are part of the broader category of strut and hanger hardware, frequently used alongside threaded rod, channel systems (like Unistrut), bridle rings, conduit hangers, and trapeze supports.

Bearing Cap screw

A bearing cap screw is a type of high-strength fastener used to secure a bearing cap in place over a bearing housing or journal. The bearing cap is a critical component that holds a bearing in alignment, preventing movement and maintaining the proper fit of a rotating shaft or other supported component. The screws (or bolts) that fasten the cap must withstand heavy loads, vibration, and stress, which is why they are designed for strength and reliability.

Bearing cap screws are usually precision-engineered bolts, often made from alloy or high-grade steel, with specific torque requirements to ensure even clamping pressure. They may also feature special head designs, such as hex or flange heads, that help distribute load more effectively. Because of the critical role they play, these screws are often paired with locking features such as thread-locking compounds, lock washers, or precise torque specifications to prevent loosening under vibration.

They are commonly used in engines, gearboxes, pumps, compressors, and heavy machinery—anywhere that a bearing cap must remain firmly fixed to prevent misalignment, excessive wear, or catastrophic failure of rotating components.

In summary, a bearing cap screw is a specialized, high-strength bolt designed to fasten a bearing cap securely over a bearing housing, ensuring alignment, stability, and long-term durability of rotating machinery.

Bearing Lock Nut

A bearing lock nut is a specialized type of nut used to secure bearings onto a shaft and ensure they remain in the correct position during operation. It works in combination with a lock washer or locking mechanism to prevent loosening caused by vibration, load shifts, or rotational forces.

Bearing lock nuts are typically precision-machined with threads that match the shaft, and they often feature slots, grooves, or notches around their circumference. These features allow a lock washer tab or a special tool (like a spanner wrench) to engage, ensuring the nut stays tight against the bearing or machine component.

The purpose of a bearing lock nut is to maintain proper preload and axial positioning of the bearing. Correct preload ensures that the bearing runs smoothly, avoids excessive play, and reduces the risk of premature wear or failure.

They are widely used in industrial machinery, automotive drivetrains, gearboxes, pumps, and rotating equipment—anywhere bearings must be fixed securely on shafts under high loads and vibration.

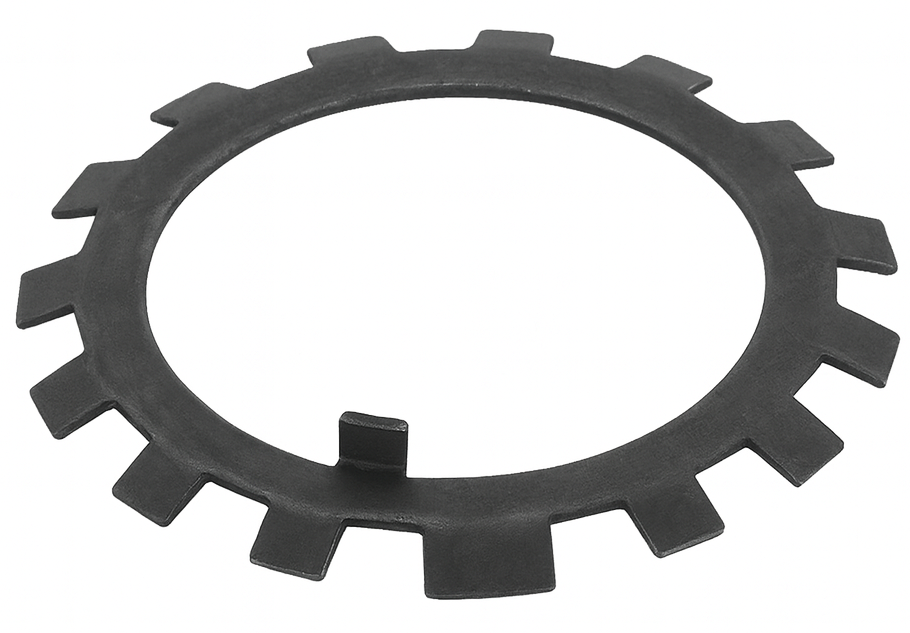

Bearing Lock Washer

A bearing lock washer is a specialized washer designed to secure a bearing nut (sometimes called a locknut) in place on a shaft, ensuring that the nut does not loosen under vibration, torque, or operational loads. These washers are typically used in combination with locknuts in bearing assemblies on shafts, spindles, or housings.

The lock washer usually has one or more tabs, keys, or tangs that fit into a slot or keyway on the shaft or in the bearing housing. This prevents the washer itself from rotating. Around its inner or outer edge, the washer also has small upturned tabs or projections that can be bent over against the flats of the nut once the nut is tightened. By doing so, the washer mechanically locks the nut in position.

Bearing lock washers are most commonly used with precision bearings in automotive, industrial, and machinery applications. They are critical in assemblies where maintaining preload on a bearing is essential for proper operation and long service life. Without a secure locking method, a bearing nut could back off during operation, leading to misalignment, excessive wear, or even catastrophic bearing failure.

Bearing Stress

Bearing stress is the localized compressive stress that develops when a fastener, such as a bolt, rivet, or pin, presses against the wall of the hole it is fitted into. This type of stress is especially important in structural and mechanical joints, because if it becomes too high, the hole can deform, elongate, or even cause the surrounding material to fail. Bearing stress only occurs in the region where the fastener makes contact with the hole, and the pressure is not evenly distributed—typically, the highest concentration of stress is found at the edge of the hole in the direction of the applied force.

The intensity of bearing stress is calculated by dividing the applied load by the product of the fastener’s diameter and the thickness of the material being clamped. In simple terms, the greater the load, the higher the bearing stress, but using a larger fastener diameter or a thicker plate spreads the force over a larger area and reduces the stress. This relationship explains why engineers carefully consider fastener size and material thickness when designing connections.

Bearing stress is compressive in nature and depends heavily on the fit between the fastener and the hole. A tight, properly sized fit distributes the load more evenly, while a loose fit allows the stress to concentrate in smaller areas, increasing the risk of damage. Because of this, bearing stress must be carefully evaluated alongside shear and tensile stresses when designing connections.

It plays a critical role in the performance of bolted, riveted, and pinned joints used in structural engineering, machinery, aerospace, and many other applications. By controlling bearing stress, designers ensure that joints maintain their strength and reliability under load, preventing premature wear, deformation, or catastrophic failure.

Bearing Surface

A bearing surface is the contact area between two components that supports a load and allows relative motion—either sliding, rolling, or rotating—while minimizing friction, wear, and deformation. In mechanical engineering and fastener design, the term refers to the portion of a part that directly bears against another surface to transmit or distribute force.

In the context of fasteners (such as bolts, nuts, and washers), the bearing surface is the underside of the bolt head or nut—the flat or slightly curved area that presses against the mating material when the fastener is tightened. This surface spreads the clamping load over a defined area to prevent damage, embedment, or localized stress on the joint material. For example, a hex bolt’s bearing surface is the flat area beneath its head that contacts the washer or joint surface, while a washer’s bearing surface is the area against which the nut or bolt head turns.

In machinery and mechanical assemblies, bearing surfaces appear in components that support shafts, slides, or rotating parts—like in bushings, journal bearings, or thrust washers. These surfaces are engineered to reduce friction and wear through smooth finishes, lubrication, or use of specialized materials such as bronze, PTFE, or hardened steel.

The quality of a bearing surface is determined by factors like:

- Flatness and smoothness – affects load distribution and friction.

- Material hardness – resists deformation under load.

- Lubrication – reduces friction and heat.

- Contact area – larger surfaces distribute loads better but may increase friction if not properly lubricated.

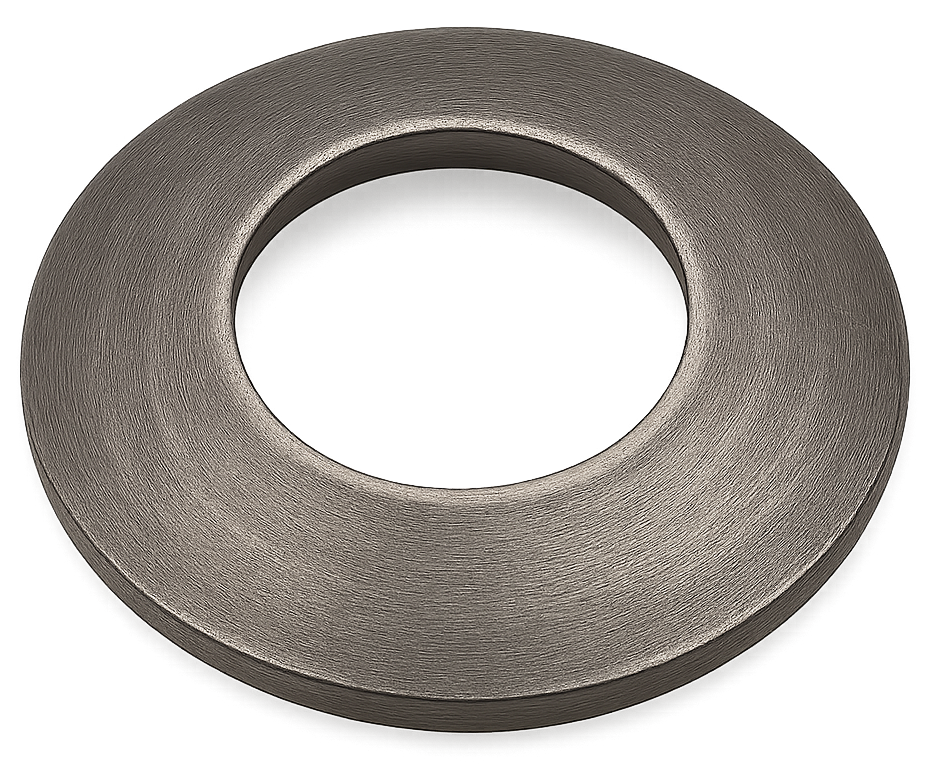

Belleville Spring Washer

A Belleville spring washer is a conical-shaped disc that acts like a spring within a bolted or fastened joint. Unlike flat washers that simply distribute load, a Belleville washer flexes under compression, creating a reactive force that maintains tension even as the joint expands, contracts, or vibrates. Sometimes called conical spring washers or Belleville disc springs, they are named after Julien Belleville, the French engineer who patented the design in the 19th century.

The washer’s shallow cone shape allows it to deflect elastically when tightened under a bolt or nut. This action helps maintain clamping force despite joint relaxation, thermal expansion, or material creep, while also absorbing shock and vibration to prevent loosening. Belleville washers can also spread loads more evenly across a joint. Multiple washers can be stacked to tailor their performance: stacking in parallel increases load capacity, stacking in series increases deflection, and combining both allows for customized load-deflection behavior.

Belleville washers offer several advantages. They provide high load capacity in a compact form, maintain bolt tension under dynamic conditions, and perform well in vibration-prone environments. They can be tailored through stacking and are available in various materials, including carbon steel, stainless steel, and Inconel, to meet strength and corrosion resistance requirements.

These washers are widely used across industries. In automotive and aerospace, they are found in engines, brakes, suspensions, and landing gear. In power generation and heavy industry, they are used in turbines, compressors, and machinery to handle thermal expansion. In electronics, they maintain reliable pressure on connectors, while in structural and mechanical joints, they add security to fasteners exposed to fluctuating loads.

Overall, Belleville spring washers are essential where maintaining clamping force is critical. Their ability to deliver high spring force in a small space makes them indispensable in safety-critical and high-performance applications, often preferred over coil springs or wave washers for compact, reliable load management.

Bent Arm Pin

A bent arm pin is a type of quick-release pin or fastener characterized by a straight pin body with an arm or handle bent at an angle from the main shaft. The bent arm functions as a lever or handle, making it easy to insert, remove, or lock the pin into place by hand, often without the need for tools. This makes it especially convenient in applications where frequent fastening and unfastening is required.

In terms of design and construction, a bent arm pin typically consists of a cylindrical pin made from durable materials such as steel, stainless steel, or other strong alloys. One end of the pin is plain or slightly chamfered to allow smooth insertion into a hole, while the opposite end features a bent arm that extends outward at a right angle or a curved shape. This bent section acts as a gripping point for quick manual operation. Some designs may also include additional features such as a retaining ring groove, a cotter pin hole, or a spring-loaded mechanism to enhance security and keep the pin locked in place during use.

The purpose of a bent arm pin is to serve as a quick, removable fastening solution that requires no tools for operation. The bent arm provides leverage and grip, allowing users to easily maneuver the pin, even when wearing gloves or working in confined areas. These pins are designed to temporarily or semi-permanently hold parts together, while still permitting frequent disassembly or adjustment when needed.

Bent arm pins are used in a wide range of applications. In agriculture and construction equipment, they are commonly used for securing linkages, hitches, or implements. In industrial machinery, they hold assemblies, guards, or components that need to be removed quickly. In transportation and trailers, they are often used to lock couplers, ramps, or gates. They are also found in general hardware applications wherever a strong but quickly removable pin is required.

These fasteners provide several advantages. They allow tool-free installation and removal, are easy to handle even in restricted access situations, and are durable enough to be reused across many cycles. However, bent arm pins also have limitations. They are not as strong or permanent as threaded fasteners or welded connections, which restricts their use in high-strength or permanent installations. Depending on the design, they may also require an additional retainer, such as a clip or cotter pin, to prevent accidental disengagement.

Beryllium Copper (BeCu)

Beryllium Copper (BeCu), also known as copper beryllium or spring copper, is a high-performance copper alloy containing a small percentage of beryllium—usually between 0.5% and 3%—along with possible additions of nickel or cobalt. Even though the beryllium content is low, the alloy delivers an exceptional balance of properties, including strength, hardness, conductivity, and corrosion resistance. This unique combination makes BeCu one of the most versatile and valuable copper-based alloys available.

BeCu is notable for its impressive properties. After heat treatment, it can achieve strength levels comparable to hardened steel while still maintaining toughness. It provides good electrical and thermal conductivity, though not as high as pure copper, and resists corrosion, oxidation, galling, and wear even in harsh environments. The alloy is non-sparking, which makes it safe for use in explosive or flammable settings such as refineries, oil rigs, and aerospace fueling operations. It is also non-magnetic, making it useful in environments where magnetic interference must be avoided. In addition, it has outstanding fatigue resistance and elasticity, making it ideal for use in springs, connectors, and components subject to repeated stress.

The advantages of BeCu extend further. Through heat treatment, its hardness and strength can be precisely tailored to suit specific applications. It uniquely combines mechanical durability with good conductivity, maintaining performance across a wide temperature range and offering long service life in high-cycle or demanding environments.

Because of these characteristics, Beryllium Copper is used across many industries. In electrical and electronics, it is found in connectors, switches, relays, circuit breakers, and precision springs. In aerospace and automotive, it is applied in components exposed to vibration, fatigue, and extreme operating conditions. In oil, gas, and mining, BeCu is used to make non-sparking tools, drill bushings, and safety-critical equipment. The defense and marine sectors use it where corrosion resistance and non-magnetic properties are vital. It is also widely applied in precision instruments, such as measuring devices, sensors, and delicate mechanical systems requiring both strength and accuracy.

One important consideration is safety. While Beryllium Copper is safe to handle in solid form, the dust or fumes produced during machining, grinding, or welding can be hazardous if inhaled. For this reason, strict safety protocols must be followed when processing BeCu to prevent health risks associated with beryllium exposure.

AKA: Copper Beryllium, Spring Copper

Bi-metal Fastener

A bi-metal fastener is a fastener made from two different metals joined together to take advantage of each material’s unique properties. Typically, one metal provides strength and structural integrity, while the other offers corrosion resistance, thermal resistance, or cost savings.

A common example is a stainless steel and aluminum bi-metal fastener: the stainless steel head and shank provide durability and corrosion protection, while the aluminum section minimizes weight or prevents galvanic corrosion when fastening to aluminum panels. Another example is a steel fastener with a stainless steel cap, often used in roofing or cladding to combine strength with weather resistance.

Construction and roofing (steel screws with stainless or coated heads for outdoor durability).

Automotive and aerospace (lightweight aluminum paired with high-strength alloys).

Electronics and appliances (to manage conductivity and corrosion in dissimilar materials).

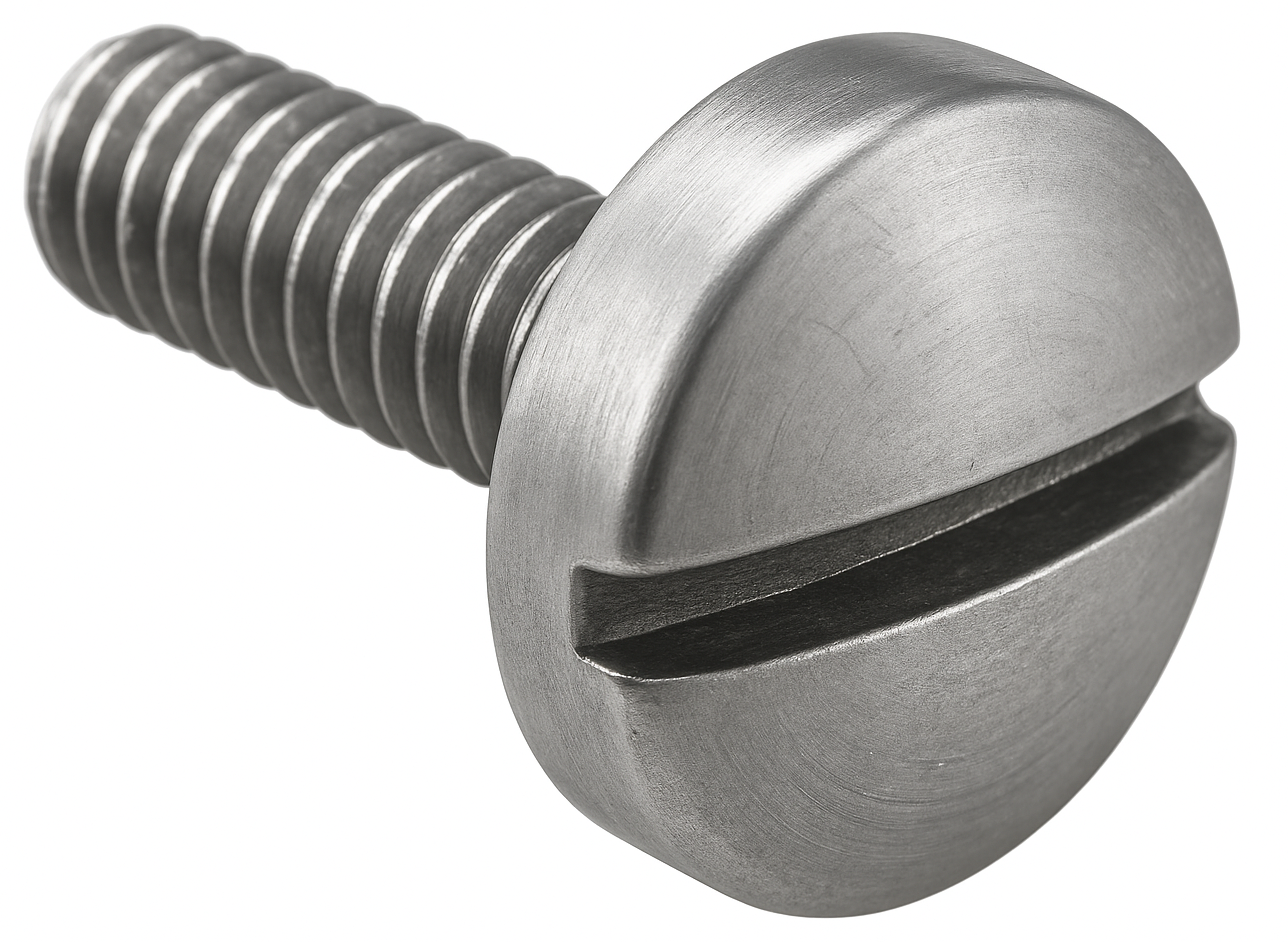

Binding Head Screw

A binding head screw is defined by its wide, low-profile head with a flat underside and a slightly rounded top. The head's large surface area effectively distributes force, which is ideal for applications where the fastened material might otherwise be damaged or pulled through by a smaller screw head. The shallow, rounded edges of the head also give it a clean, finished look while maintaining solid contact with the surface. These screws are available with various drive types, including slotted and Phillips, making them a versatile choice for different projects.

They are commonly used in a variety of fields. In electrical applications, the large head securely holds delicate components and terminals. The name "binding" comes from their traditional use in bookbinding and stationery to fasten books or paper stacks. They are also widely used in electronics and machinery where a broad holding surface is necessary, but without the need for countersinking. Overall, the binding head screw is a practical solution that offers a balance of strength, a wide bearing surface, and a clean finish, making it a great option for projects where both function and appearance matter.

Binding Self-Drilling Screw

A binding self-drilling screw is a type of self-drilling fastener designed to secure thin materials together—typically sheet metal, aluminum, or light steel—without the need for pre-drilling a pilot hole. The “binding” designation refers to its low-profile head, which is ideal when a flush, clean finish is needed.

Bismuth (Bi)

Bismuth is a brittle, silvery-white metal with a pinkish tint that sits on the periodic table as element 83 (Bi). It’s classified as a post-transition metal, and it is well known for its low melting point, unusual rainbow-oxide colors, and its tendency to form geometric, hopper-shaped crystals.

Bismuth is one of the heaviest naturally occurring elements that is not significantly radioactive. It’s extremely dense—heavier than lead—but is considered much safer and less toxic, which is why it has replaced lead in many modern alloys.

Industrially, bismuth is valued because it melts easily and expands slightly when it solidifies. This makes it useful in fusible alloys, which melt at low temperatures for safety devices like sprinkler heads and fusible plugs. It also appears in pharmaceuticals (like Pepto-Bismol), cosmetics, low-melting solders, precision casting alloys, and fire-detection devices.

In pure form it has very low thermal conductivity (one of the lowest among metals), is diamagnetic (repelled by magnetic fields), and forms striking iridescent oxide layers. Bismuth is typically produced as a byproduct of lead, copper, tin, silver, and tungsten mining, making it relatively rare but industrially valuable.

Blank

A raw or unfinished piece of material that will be further machined, shaped, or processed into a finished part. In fastener manufacturing, a blank typically refers to the basic form of a bolt, screw, or nut before threads are added and surface treatments are applied.

Blanket Orders

A purchasing agreement where a buyer places a long-term order with a supplier for a specified quantity of products or materials to be delivered over time. In some cases, the supplier keeps the inventory stored in their warehouse and ships it to the buyer as needed. This arrangement helps streamline ordering, reduce administrative costs, and ensure a consistent supply without needing to issue multiple individual purchase orders.

Blast Furnace

A blast furnace is a large, vertical, cylindrical industrial furnace used to extract iron from iron ore through a chemical reduction process. It is the central piece of equipment in traditional ironmaking, producing molten pig iron, which is later refined into steel or cast iron. The term “blast” refers to the continuous flow of hot, pressurized air (or oxygen-enriched air) that’s blown into the furnace to sustain combustion and drive the chemical reactions.

Structure and Design

A blast furnace is typically a tower-shaped structure, about 30–40 meters (100–130 feet) tall and lined with refractory firebrick to withstand the extreme internal temperatures (up to 2000°C / 3600°F). It is divided into several zones:

1. Throat (Top): Where the raw materials—iron ore, coke, and limestone (flux)—are charged into the furnace in alternating layers.

2. Stack: The middle section where the rising hot gases preheat and partially reduce the descending ore.

3. Bosh: The hottest region, where combustion occurs, and reduction reactions intensify.

4. Hearth (Bottom): The lowest part, where molten pig iron and slag collect and are periodically drained (tapped) through separate openings.

Raw Materials

A blast furnace requires three main ingredients:

- Iron ore (hematite Fe₂O₃ or magnetite Fe₃O₄): The source of metallic iron.

- Coke: A carbon-rich fuel made from coal that burns to produce heat and carbon monoxide.

- Limestone (CaCO₃): Acts as a flux, combining with impurities like silica to form slag, which floats on top of the molten iron.

Process

The blast furnace operates continuously, with materials fed from the top while air is blown in from the bottom through tuyeres (nozzles). Several key reactions occur:

1. Combustion of coke:

C + O2 → CO2

and then

CO2 + C → 2CO

This produces carbon monoxide (CO), the main reducing agent.

2. Reduction of iron ore:

Fe2O3 + 3CO → 2Fe + 3CO2

The iron oxide is reduced to metallic iron, which melts and collects at the bottom as pig iron.

3. Formation of slag:

CaCO3 → CaO + CO2

CaO + SiO2 → CaSiO3

The lime (CaO) reacts with silica and other impurities to form liquid slag, which floats above the molten iron.

Products

- Molten pig iron: The main product, containing about 3.5–4.5% carbon, along with silicon, manganese, sulfur, and phosphorus.

- Slag: A byproduct used in cement production, road construction, and insulation materials.

- Top gas: A mixture of CO, CO₂, and N₂ that can be recovered and reused as a fuel or reducing gas.

Significance

The blast furnace is the heart of the iron and steel industry, providing the raw pig iron that’s refined into steel in a basic oxygen furnace (BOF) or electric arc furnace (EAF). Despite being centuries old in principle—the earliest versions date back to the 14th century—it remains one of the most efficient large-scale metallurgical systems ever developed.

Blind Hole

A blind hole is a hole that goes into a material but does not pass all the way through it. It has a specific, controlled depth and a closed bottom, which makes it different from a through hole that extends from one side of a workpiece to the other.

Creating a blind hole requires precision, as the depth must be carefully controlled. Machining them also requires extra attention to remove chips and debris that can build up at the bottom of the hole. Blind holes are frequently used for threaded fasteners, allowing for bolts or screws to be secured without protruding from the other side. This is beneficial for maintaining a clean appearance, ensuring a tight seal in fluid systems, or preserving the strength of the material on the opposite side. An example of this is when a machine housing has a blind tapped hole that allows a cover plate to be fastened, all while keeping the internal components sealed and protected.

Blind Rivet

A blind rivet (or pop rivet) is a fastener used when only one side of the workpiece is accessible. It consists of a rivet body (shell) and a mandrel (stem). The rivet is inserted into a pre-drilled hole with the mandrel sticking out, and a rivet gun pulls the mandrel while holding the rivet body in place. This causes the blind end of the rivet body to expand and flare out, clamping the materials together. Once secured, the mandrel snaps off, leaving a finished head on one side and the deformed rivet body holding the materials from the other side.

Blind rivets are widely used in aerospace, automotive, construction, sheet metal, and electronics because they are quick to install, lightweight, and can be applied from one side only. However, they are generally not as strong as structural bolts or welds for heavy load-bearing applications.

Blind Rivet Gun

A blind rivet gun is a tool used to install blind rivets, also known as pop rivets. Blind rivets are unique because they can be set from one side of the workpiece, which makes them especially useful in applications where the back side is inaccessible. The rivet gun works by gripping and pulling the rivet’s mandrel while holding the rivet body in place. As the mandrel is drawn back, it forces the rivet body to expand and flare out on the hidden side, clamping the materials together. Once the required force is reached, the mandrel snaps off at its designed break point, leaving behind a secure, permanent joint.

There are different types of blind rivet guns suited for different applications. Manual rivet guns are hand-operated and best for small jobs or lighter materials. Pneumatic rivet guns are powered by compressed air and are common in industrial or manufacturing settings where large numbers of rivets must be installed quickly. Cordless electric rivet guns are battery-powered, offering portability and reduced operator fatigue without the need for air hoses.

Blind rivet guns are widely used in sheet metal work, automotive repair, aerospace assembly, construction, and many DIY projects. They provide a strong, vibration-resistant fastening method and allow for fast, efficient installation. In short, a blind rivet gun is a specialized fastening tool that pulls the mandrel of a blind rivet to deform its body, securing materials together from just one accessible side.

Blind Threaded Stud Inserts

Blind Threaded Stud Inserts are fasteners designed to provide a strong, load-bearing threaded stud in thin or soft materials (like sheet metal, plastic, or composites), and—crucially—they can be installed from one side only (the “blind” side).

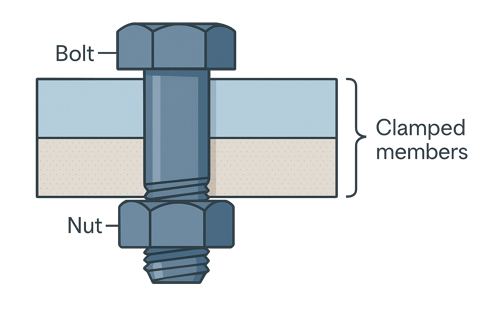

Bolt

A fastener with an external thread designed to be inserted through aligned holes in assembled parts and secured with a nut. Bolts provide clamping force to hold components together and are commonly used in applications where disassembly and reassembly are needed. They come in various head styles and grades to suit different strength and installation requirements.

Bolt Preload

Bolt preload is the tension, or stretch, intentionally created in a bolt when it's tightened. This tension generates a powerful clamping force between the bolt's head (or nut) and the materials being joined. By stretching the bolt like a spring, the tightening process creates a tensile force within the bolt and an opposing compressive force on the joint, effectively holding the parts together securely. This "built-in" clamping force is crucial for ensuring a joint remains stable and reliable, resisting external stresses like vibration, shear forces, and thermal expansion.

The proper application of bolt preload is essential for several reasons. It prevents loosening by keeping joints secure even under dynamic loads and vibrations. Preload also ensures that external forces are distributed evenly between the bolt and the joint, protecting the bolt from bearing the entire load. This stress distribution helps to avoid fatigue failure, significantly improving the bolt's lifespan. Additionally, in applications involving gaskets, preload is vital for compressing the gasket to create a leak-proof seal.

Several factors influence the amount of preload a bolt achieves. While applied torque is the most common method for creating preload, its effectiveness can be inconsistent due to friction. Lubrication plays a significant role, as it reduces friction at the threads and under the bolt head, allowing more of the applied torque to be converted into clamping force. The bolt's material and geometry also matter, as stronger bolts can withstand higher preloads without yielding. Finally, different tightening methods, such as angle tightening or direct tensioning, can offer more precise control over the resulting preload than simple torque application.

Bolt Retainer

A bolt retainer is a device or feature that holds a bolt in place so it doesn’t fall out, shift, or get lost before or after the nut is installed. Its purpose is captivation and positioning—not preventing loosening, which is handled by lock nuts, thread-locker, or tab washers. Retainers speed assembly in blind or overhead locations, keep hardware with the part during shipping and service, and help maintain alignment under vibration.

Bolt retainers appear in several forms. Spring-steel clips snap into a panel hole and grip the bolt’s shank or head to keep it captive. Plastic or nylon retainers and grommets push into a hole and hold the bolt by friction for one-hand assembly. Retainer or captive washers press onto the shank to keep the washer and/or bolt attached to the part. Retainer plates or straps capture bolt heads or T-bolts in slots so they can’t drop out, common in automotive and machinery. Some retainers are adhesive or pre-applied patch materials that add light holding force to keep a bolt from backing out during handling, though they are not primary locking devices.

Typical applications include automotive body and chassis assembly, HVAC and appliance panels, equipment enclosures, and any situation where a bolt must be pre-positioned or remain with the component for service.

Bolt Shaft

The main cylindrical body of a bolt, extending from directly beneath the head to its tip. It encompasses both the unthreaded portion, commonly referred to as the shank, and the threaded portion designed for engagement with a nut or tapped hole. Essentially, it's the entire length of the bolt's body that provides its structural connection.

Bolted Joint

A bolted joint is a connection that uses a bolt and a mating thread (a nut or tapped hole) to clamp two or more parts together. Tightening stretches the bolt like a spring and compresses the jointed parts; this elastic stretch creates preload (clamp force) that holds the assembly together and resists service loads.

There are two basic ways a bolted joint carries load. In a preloaded (friction) joint, the external shear is resisted by friction between the clamped parts; if the service load stays below the clamp force, the parts don’t slip and the bolt mainly sees tension from its initial preload. In a bearing/shear joint, the parts are allowed to slip until the bolt shank bears against the holes, so the bolt carries shear and the holes carry bearing stress. Many practical joints rely on a mix of both.

Joint behavior depends on stiffness: the bolt (in tension) and the clamped members (in compression) act like springs in series, sharing any additional external load. If the external tensile load exceeds the preload, the joint begins to separate (loss of compression), after which the bolt takes the extra load directly—this is when fatigue risk rises quickly.

Key design choices include bolt size and strength grade/property class, grip length, whether the shear plane lies on the smooth shank (preferred) or threads, and the amount of preload, commonly set to ~70–90% of bolt proof strength for structural joints. Preload can be achieved by torque (affected by friction and lubrication), torque-angle/turn-of-nut, tensioners, or load-indicating devices. Locking and back-out prevention are provided by prevailing-torque nuts, thread-locking compounds, lock washers, tab/safety wire, or joint features.

Typical failure modes are insufficient preload leading to loosening, thread stripping (internal or external), bolt yielding or fracture (often fatigue), hole bearing or tear-out, and embedment/relaxation that reduces clamp force over time. Good practice is adequate thread engagement (≈1–1.5× bolt diameter in steel), keeping threads out of the shear plane, using appropriate washers or hardened surfaces, controlling friction in torque specs, and verifying preload where critical.

Bonding Screw

A bonding screw is a specialized electrical fastener used to create a reliable electrical connection—or bond—between metal components, ensuring electrical continuity and grounding in electrical systems. Its main function is to securely connect the grounding conductor to a metal enclosure, such as an electrical box, panel, or conduit fitting, helping to safely carry stray electrical currents to ground and prevent electric shock or fire hazards.

Bonding screws are typically made of conductive metals such as copper, brass, or zinc-plated steel, which provide both mechanical strength and excellent electrical conductivity. The screw often has a distinctive green finish, which identifies it as a grounding or bonding component according to NEC (National Electrical Code) standards in the U.S.

In use, the bonding screw threads into a pre-tapped hole inside an electrical box or enclosure. A grounding wire or lug is attached under its head, ensuring a tight metal-to-metal contact between the wire and the enclosure. This creates a continuous grounding path throughout the system, equalizing electrical potential between all conductive parts.

Bonding screws are common in panelboards, switchgear, outlet boxes, junction boxes, and conduit systems, where grounding is required by code. Their design often includes a flat or undercut head to improve electrical contact and prevent loosening over time due to vibration.

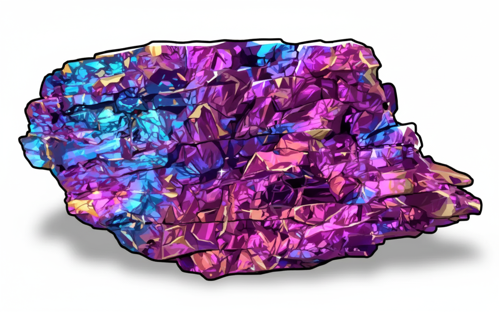

Bornite

Bornite is a copper iron sulfide mineral with the chemical formula Cu₅FeS₄, known for its distinctive metallic luster and vibrant iridescent tarnish that displays shades of purple, blue, red, and gold—earning it the nickname “peacock ore.” When freshly broken, bornite has a brownish-bronze color, but exposure to air and moisture causes oxidation that produces its striking, colorful surface.

Bornite crystallizes in the orthorhombic system at high temperatures and converts to the cubic system upon cooling below 228°C. It is relatively soft (3.0 on the Mohs hardness scale) and has a metallic to submetallic luster with poor cleavage and a dark gray to black streak.

This mineral is a major copper ore, typically containing about 63% copper by weight, and is mined extensively for industrial copper production. Bornite is often found in hydrothermal veins, contact metamorphic zones, and porphyry copper deposits, commonly associated with other copper minerals such as chalcopyrite, chalcocite, and covellite. Major sources include Chile, Peru, the United States (especially Arizona and Montana), Australia, and Namibia.

In industrial applications, bornite’s primary value lies in its role as a copper source—it is smelted and refined to extract pure copper metal used in electrical wiring, plumbing, alloys, and electronics.

Scientifically, bornite is also of interest for its semiconducting properties, and researchers have studied it for use in photovoltaic (solar) materials due to its natural abundance and favorable electronic structure.

AKA: Peacock Ore

Boron (B)

Boron is a metalloid element with the chemical symbol B and atomic number 5. It occupies a unique position on the periodic table—situated between metals and nonmetals—and displays properties of both. Boron is hard, brittle, and black in its pure crystalline form, yet it can also exist as an amorphous brown powder. It is chemically reactive at high temperatures and forms compounds that are vital in industry, metallurgy, materials science, and even biology.

In nature, boron is never found in its pure elemental state. Instead, it occurs in borate minerals such as borax (Na₂B₄O₇·10H₂O), kernite, and ulexite, which are commonly mined in dry lake beds and arid regions—most notably in Turkey, the U.S. (California), and South America. These minerals are the primary source for industrial boron compounds.

Boron’s chemical versatility stems from its ability to form strong covalent bonds and complex molecular structures, including borates, borides, and boranes. One of its defining features is its electron deficiency, which allows it to form compounds with unusual bonding arrangements, making it an important element in high-performance materials.

In practical use, boron and its compounds play major roles across industries. Boron oxide (B₂O₃) is a key ingredient in borosilicate glass, known for its heat and chemical resistance (used in Pyrex®). Boron carbide (B₄C) and titanium diboride (TiB₂) are superhard materials used in armor plating and cutting tools. Sodium borates are widely used in detergents, fertilizers, and flame retardants. In metallurgy, boron is added in trace amounts to steels and alloys to improve hardness, wear resistance, and grain structure.

Boron is also crucial in electronics and energy. It acts as a semiconductor dopant, especially in silicon-based devices, and plays a role in nuclear reactors as a neutron absorber due to the high neutron cross-section of the isotope boron-10. Additionally, in agriculture, boron is an essential micronutrient for plants, aiding in cell wall formation and sugar transport.

Boron Carbide (B₄C)

Boron carbide (B₄C) is an extremely hard ceramic composed of boron and carbon. It is one of the hardest known materials, ranking just below diamond and cubic boron nitride, which makes it highly valuable for applications where exceptional hardness, wear resistance, and low weight are critical. Because of its unique properties, boron carbide is widely used in industrial, defense, and nuclear applications.

The material’s structure gives it outstanding mechanical properties. It has a hardness of about 9.5 on the Mohs scale and a very high melting point exceeding 2,700 °C (4,892 °F). Despite being extremely hard, it is relatively lightweight, with a density of only about 2.52 g/cm³, which is much lighter than metals such as steel. Boron carbide also offers excellent resistance to chemical attack and remains stable in harsh environments. However, like other ceramics, it is brittle and can fracture when exposed to high-impact loads or tensile stresses.

Boron carbide is manufactured synthetically rather than mined. It is typically produced by reacting boron oxide (B₂O₃) with carbon in an electric arc furnace at very high temperatures. The resulting crystalline material can be ground into powders, hot-pressed into solid components, or incorporated into composites, depending on the intended application.

Its applications are wide-ranging. In defense and security, boron carbide is widely used in body armor, vehicle armor, and protective shields because it combines extreme hardness with very low weight, making protection both effective and practical. In industrial uses, it serves as an abrasive for grinding, lapping, and polishing hard materials. In the nuclear industry, it is an important neutron absorber for control rods and shielding due to boron’s high neutron capture capability. It is also used in sandblasting nozzles, pump seals, and other wear-resistant parts, as well as in refractory materials designed for high-temperature environments.

The advantages of boron carbide include its extreme hardness and wear resistance, lightweight nature compared to metals, high chemical and thermal stability, and neutron absorption capability that makes it essential in nuclear applications. However, it also has limitations. Its brittleness makes it prone to cracking under sharp impact or tensile stress. It is also expensive to produce and process, and its extreme hardness requires specialized equipment for machining and shaping. Despite these challenges, boron carbide remains one of the most valuable advanced ceramics for critical applications where strength, durability, and lightweight performance are essential.

Bottoming Tap

A bottoming tap is a specialized type of hand or machine tap designed to cut internal threads all the way to the bottom of a blind hole, which is a hole that does not pass completely through the material. Its design allows it to create threads in areas where other taps cannot reach, making it essential for applications requiring maximum thread depth.

What makes a bottoming tap distinct is its thread form. The cutting threads extend almost the entire length of the tap, with only the first one or two threads at the tip being slightly chamfered, or tapered. This minimal chamfer is what allows the tap to cut threads as close as possible to the bottom of the hole, maximizing the usable depth of the threads.

When compared to other taps, the difference becomes clearer. A taper tap has a long chamfer covering about 6 to 10 threads, which makes it ideal for starting the threading process in a hole. A plug tap, with its medium chamfer of 3 to 5 threads, is typically used after the taper tap to advance the threads further. The bottoming tap, with just 1 to 2 chamfered threads, is used last in the sequence to complete the threads nearly to the bottom of the hole.

Bottoming taps are commonly used in situations where the full depth of a blind hole needs to be threaded for strength, or where a fastener must seat as deeply as possible within the material. This makes them indispensable in precision applications where every bit of thread engagement is critical to the performance and reliability of the assembly.

Brad Nail

A brad nail is a small, thin finishing nail typically used for light woodworking and trim work where a discreet, nearly invisible fastener is desired. Brad nails are usually made of 18-gauge steel wire, making them thinner and more flexible than standard finishing nails.

They are most commonly installed using a brad nailer (a type of pneumatic or electric nail gun) that drives them quickly and precisely into materials such as molding, baseboards, picture frames, cabinetry, or decorative trim. Because they are so thin and have small heads, brad nails leave minimal surface marks and often don’t require wood filler after installation.

Unlike thicker nails, brads are ideal for delicate or thin materials that might split under the force of larger fasteners. However, they have limited holding strength, so they’re not suitable for structural applications or for securing heavy components.

Brad Point Drill Bit

A Brad point drill bit (also called a lip and spur bit) is a specialized type of drill bit designed for clean, precise holes in wood, plastic, and soft materials. It features a sharp center point (the “brad”) that helps position the bit exactly where the hole is to be drilled, preventing it from wandering or slipping on the surface.

The bit’s cutting edges, or “spurs,” are located on the outer rim and slice the wood fibers ahead of the main cutting edge. This design produces clean, smooth, and accurately sized holes with minimal tear-out or splintering, even near the edges of a workpiece.

Brad point bits typically have a twist design for chip removal and are made from high-speed steel (HSS), carbon steel, or carbide-tipped materials, depending on the application. They are especially popular in cabinetry, furniture making, doweling, and fine woodworking, where precision and surface finish are critical.

Brass (Metal Alloy)

Brass is a metal alloy made primarily of copper (Cu) and zinc (Zn). It is known for its bright gold-like appearance, excellent corrosion resistance, and workability, making it one of the most widely used and versatile alloys in both industrial and decorative applications.

The exact properties of brass vary depending on the ratio of copper to zinc and the presence of small amounts of other elements such as lead, tin, aluminum, or nickel. Typically, brass contains 55–95% copper and 5–45% zinc.

- Higher copper content produces a softer, more ductile brass with a deeper reddish tone and superior corrosion resistance.

- Higher zinc content yields stronger, harder brass with a lighter yellow color but slightly reduced corrosion resistance.

Brass is valued for several key characteristics. It is malleable and ductile, allowing it to be easily machined, stamped, rolled, or cast into complex shapes. It also has low friction, non-sparking properties, and good thermal and electrical conductivity. These features make it ideal for fasteners, fittings, valves, bearings, gears, electrical connectors, and musical instruments.

Because brass resists tarnishing and corrosion—especially in water and marine environments—it is commonly used in plumbing components, marine hardware, and decorative applications like architectural accents, lamps, and door hardware. Certain types, such as naval brass and admiralty brass, include small additions of tin for enhanced resistance to saltwater corrosion.

The alloy also has favorable acoustic qualities, which is why it’s widely used in musical instruments such as trumpets, trombones, and saxophones—collectively known as “brass instruments.”

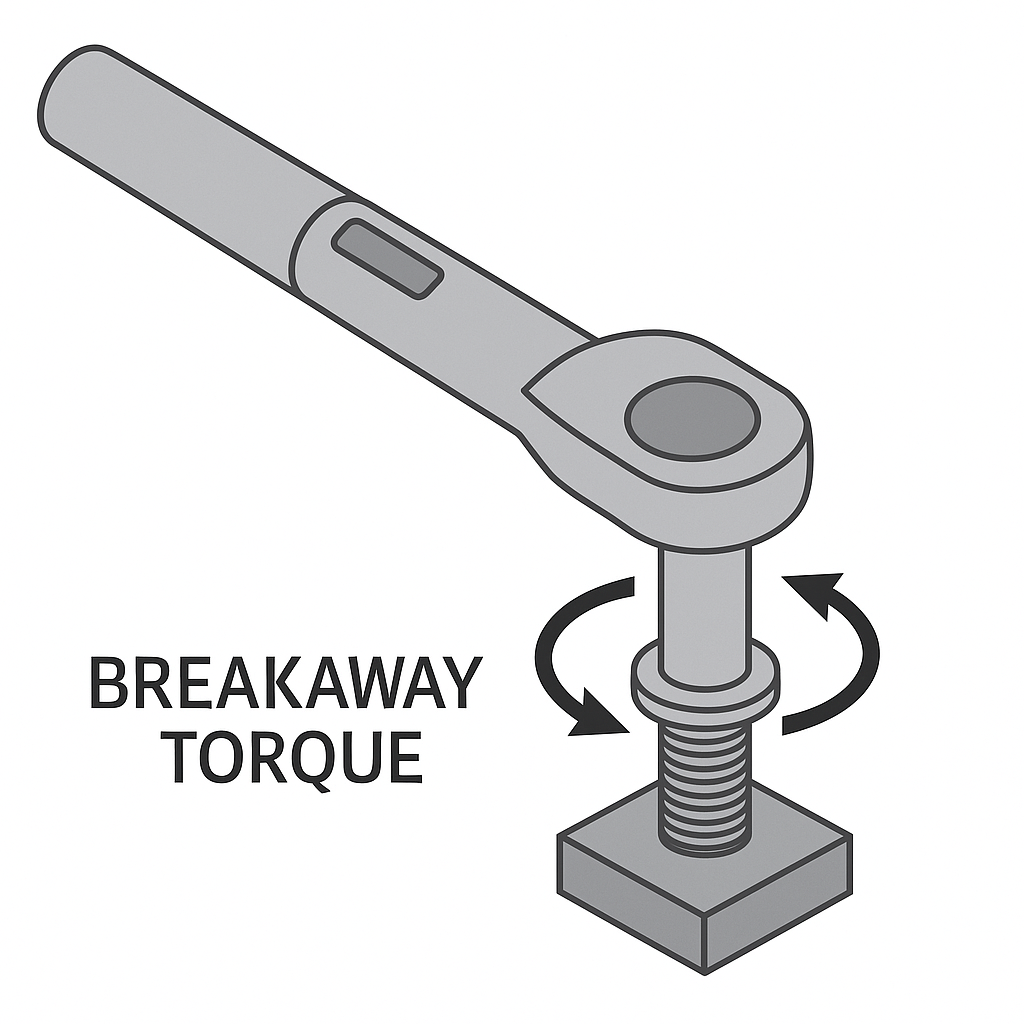

Breakaway Torque

Breakaway torque is the amount of torque needed to start turning a fastener after it has been tightened and is at rest. It measures the force required to overcome static friction between the threads or surfaces.

This value is important for testing locking fasteners, coatings, and lubricants, as well as for quality control in industries like aerospace and automotive. It ensures that fasteners resist loosening and remain secure under vibration or load.

Breaker Bar

A breaker bar is a long, non-ratcheting hand tool used to apply high torque for loosening very tight or rusted fasteners, such as bolts and nuts. It looks similar to a socket wrench but without the ratcheting mechanism. Instead, it has a solid handle, usually made of steel, and a drive end that accepts interchangeable sockets.

The key feature of a breaker bar is its length. The extended handle provides much greater leverage compared to a standard wrench or ratchet. This leverage reduces the amount of force you need to apply with your hand in order to break free a stuck or over-tightened fastener. For example, a two-foot breaker bar allows you to generate far more torque with the same effort than a short ratchet handle.

Breaker bars are commonly used in automotive, heavy equipment, and industrial maintenance when dealing with seized, corroded, or over-torqued fasteners. They are not intended for tightening bolts to a specific torque (that’s the job of a torque wrench), but rather for the brute-force loosening of stubborn ones. Because they lack moving parts, they’re also very durable and less prone to damage under extreme force.

Bridge Bolt

A bridge bolt is a heavy-duty fastener specifically designed for structural applications, most notably in the construction of bridges, heavy timber frameworks, and other large-scale assemblies. It is built to handle substantial loads and provide long-lasting fastening in demanding environments where strength and durability are critical.

The defining features of a bridge bolt are its large, domed head (sometimes called a mushroom head) and the square neck located directly beneath the head. The square neck fits into a corresponding square hole or embeds itself into wood or metal, which prevents the bolt from rotating during tightening. This design allows for easier installation since only the nut needs to be turned with a wrench, while the bolt remains stationary.

Bridge bolts are commonly manufactured in larger diameters and lengths than standard bolts to ensure they can withstand the high stresses of structural joints. They are usually made from high-strength carbon steel or alloy steel, and many are galvanized or otherwise coated to resist corrosion. This added protection is important because bridge bolts are often used outdoors or in harsh environmental conditions.

These bolts see use in a wide range of structural applications, such as securing beams and members in bridge construction, fastening posts and trusses in heavy timber projects, and reinforcing railway and marine structures where vibration resistance and load-bearing capacity are essential.

In summary, a bridge bolt is a large, domed-head structural fastener with a square neck and threaded shank, engineered to deliver secure, high-strength fastening in bridges, heavy timber, and other demanding construction projects.

Bridge Hitch Hair Pin Clip

A Bridge Hitch Hair Pin Clip is a quick-release spring-wire retainer used to keep a hitch pin, clevis pin, or shaft from sliding out. It’s a variant of the common hair-pin (R-clip) where the straight leg passes through the cross-hole in the pin and the curved leg snaps over the outside diameter. The “bridge” is an arched hump formed near the head of the clip; it increases spring force, gives finger clearance, and helps the clip seat positively against the pin so it’s less likely to shake loose under vibration.

How it works: push the straight leg through the pin’s hole until the bridge rides against the pin or shoulder. The curved leg flexes and clamps the pin’s OD, creating a friction hold. To remove, pull on the bridge and slide the clip out—no tools required. It’s reusable and designed for frequent on/off use.

Where used: trailer couplers and drawbars, agricultural/landscaping equipment, lawn & garden attachments, material-handling fixtures—any place a hitch or clevis pin needs a fast, secure keeper that tolerates vibration.

Options & sizing: made from spring steel wire (typically zinc-plated) or stainless for corrosion resistance; available in light-duty to heavy-duty wire diameters and lengths to match common pin sizes. Choose a clip size specified for your pin diameter; replace if bent, cracked, or if spring tension feels weak.

Bridle Ring

A bridle ring is a simple, loop-shaped wire fastener used primarily to support and route cables, wires, and low-voltage lines in industrial, electrical, and construction environments. It looks like a sturdy metal ring with a threaded shank attached, allowing it to be screwed into wood, metal, or mounted with accessories like beam clamps.

Bridle rings are favored because they offer an open, low-friction pathway for cables—unlike enclosed conduits or closed hangers—making it easy to pull, add, or remove wires during installation or maintenance. They’re commonly used for CAT5/CAT6 data cables, fiber optics, low-voltage wiring, telecommunications, speaker wire, and light electrical lines. In industrial or commercial settings, they help keep cable runs organized, elevated, and protected while meeting routing standards for non-critical low-voltage systems.

They come in different ring diameters and with various mounting options such as threaded screws, machine-screw threads, or attachment-ready ends for beams or strut channels. Because the interior is open and smooth, bridle rings help minimize cable abrasion—but they’re typically limited to low-tension or non-plenum applications, unlike more rigid or enclosed cable supports.

Brinell Hardness Test

Brinell Hardness is a method of measuring how resistant a material is to indentation, giving an indication of its hardness. In the Brinell hardness test (BHN), a hard steel or tungsten carbide ball is pressed into the surface of a material under a specific load. The diameter of the indentation left behind is measured, and the Brinell Hardness Number (BHN) is calculated by dividing the load by the surface area of the indentation.

Brinell hardness testing is commonly used for metals and alloys, especially when testing large, coarse-grained materials like castings and forgings. Because it produces a relatively large indentation, it averages out hardness over a bigger area, making it especially useful for non-uniform materials.

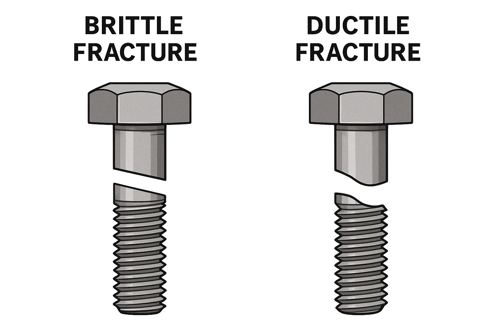

Brittle Fracture

Brittle fracture is a type of material failure that occurs suddenly and without significant plastic deformation when a material is subjected to stress. Unlike ductile fracture, where a material stretches or elongates before breaking, brittle fracture happens almost instantly once the stress exceeds the material’s strength, often with little or no warning.

In brittle fracture, cracks initiate and propagate very quickly through the material. The fracture surface is typically flat and bright, often showing a granular or crystalline appearance. Because there is no noticeable plastic deformation, the broken pieces fit back together almost perfectly, like puzzle pieces.

This failure mode is strongly influenced by factors such as temperature, loading rate, material composition, and the presence of stress concentrators (like notches, sharp corners, or internal defects). Many materials that are normally ductile, such as steel, can fail in a brittle manner if they are exposed to very low temperatures or extremely high strain rates.

Brittle fracture is especially dangerous in engineering applications because it provides little chance to detect or correct the problem before catastrophic failure occurs. For this reason, materials and fasteners used in critical structures like bridges, ships, aircraft, and pressure vessels are carefully tested and often designed with features to avoid brittle failure.

Broaching

Broaching is a machining process that removes material using a multi-tooth cutting tool called a broach to create precise shapes, holes, slots, keyways, or contours in a single linear pass. Each tooth on the broach is slightly higher than the one before it, allowing it to progressively cut deeper into the material with each step—producing a smooth, accurate finish.

There are two main types of broaching:

- Linear broaching, where the broach tool moves linearly across the workpiece (typical for internal holes or external surfaces).

- Rotary broaching, where the broach and workpiece rotate together, used mostly for hex, square, or spline shapes inside holes—common in fasteners, drive components, and aerospace parts.

The process is typically used on materials like steel, aluminum, brass, and cast iron, and can be performed on both internal and external surfaces. Internal broaching is often used to make keyways, splines, and non-round holes in components such as gears, pulleys, and bushings. External broaching is used for creating flat surfaces, slots, or specialized profiles.

Broaching is valued for its speed, accuracy, and repeatability—once a broach is made, it can produce hundreds or thousands of identical parts with minimal variation. It’s especially useful in high-volume manufacturing, where precision and consistency are critical.

Bronze (Metal Alloy)

Bronze is a metal alloy primarily composed of copper (Cu) and tin (Sn), often containing small amounts of other elements such as aluminum, phosphorus, manganese, or silicon to enhance specific properties. It is one of the oldest and most significant alloys in human history, marking the technological leap known as the Bronze Age (around 3300–1200 BCE).

Bronze was the first alloy intentionally created by humans, and it quickly replaced stone and pure copper tools because of its superior hardness, strength, and durability. Adding tin to copper changes the alloy’s crystal structure, making it stronger, less brittle, and more resistant to corrosion.

In appearance, bronze has a reddish-brown to golden color, which can darken or develop a greenish patina (a layer of copper carbonate) over time due to oxidation. This patina actually protects the metal from further corrosion, making bronze extremely durable — a reason why ancient bronze artifacts, statues, and coins often survive for millennia.

Bronze’s properties can vary depending on composition:

- Phosphor bronze (copper + tin + phosphorus) is tough, wear-resistant, and used for springs, bushings, and bearings.

- Aluminum bronze (copper + aluminum) is stronger and highly corrosion-resistant, often used in marine hardware and fasteners.

- Silicon bronze (copper + silicon) has excellent corrosion resistance and weldability, used in architecture, sculptures, and boat fittings.

Because of its low friction and non-sparking characteristics, bronze is commonly used in bearings, gears, bushings, and tools for environments where sparks could ignite gases or vapors. Its acoustic properties also make it ideal for musical instruments such as bells, cymbals, and strings for pianos and guitars.

In art and architecture, bronze has long been valued for its workability and beautiful aging, used in statues, memorials, and decorative fittings. When molten, it fills molds cleanly, capturing fine detail, which is why bronze casting remains the preferred method for sculptures.

Bugle Head Screw

A bugle head screw is a screw identified by its smoothly curved, countersunk head that resembles the flared shape of a bugle. This design allows the screw to sit flush with or just below the surface of the material after being driven in, without tearing or damaging the surrounding surface. Unlike flat head screws, which have a sharp underside angle, the bugle head tapers gently, distributing the driving force more evenly and reducing stress on softer materials such as drywall or wood.

The design of the bugle head screw enhances its performance in multiple ways. The wide, rounded flare of the head provides a large bearing surface, minimizing the risk of the screw sinking too deeply or causing surface damage. Its self-countersinking ability ensures a clean, smooth finish without requiring a separate countersinking tool. Bugle head screws are commonly paired with Phillips or square (Robertson) drives for ease of use, though other drive types are also available. They usually feature coarse threads to penetrate soft materials quickly, though fine-threaded versions are made for use with metal studs or denser substrates.

Several advantages come from this design. The gently curved underside prevents tearing of drywall paper facings or crushing wood fibers, preserving the material’s integrity. Once driven, the head sits flush, making it ideal in applications where the screw must be hidden under joint compound, filler, or finishing layers. The self-countersinking feature simplifies installation, saving time by reducing the need for pre-drilling. In addition, bugle head screws are versatile enough for both drywall and wood, with different thread designs available to suit each material.

Bugle head screws are widely used in construction and woodworking. Their most common application is drywall installation, where they secure sheets to wood or metal studs without damaging the surface. In woodworking, they are chosen when a neat, flush finish is required, such as in cabinetry or furniture projects. They also find use in general construction, including light framing, decking, and sheathing, wherever a smooth countersunk screw finish is needed.

Bulkhead Bolt

A bulkhead bolt isn’t a unique bolt type so much as a use-case term: it’s any bolt used to fasten a bulkhead—a structural partition or wall— to adjoining structure or to mount hardware through that wall. You’ll see the term in boats/ships, vehicles, and aircraft. The job is to clamp the bulkhead securely and prevent movement while respecting sealing and corrosion requirements.

In marine work, bulkhead bolts are typically 316 stainless or silicon bronze with large washers or backing plates to spread load on plywood/composite panels. Heads may be hex, pan/button, carriage (square-neck) or countersunk, chosen to sit low and avoid snagging. Holes are often bedded/sealed (e.g., with sealant or gasketed/sealing washers) to keep joints watertight; cored laminates are “potted” so the core isn’t crushed.

In aerospace/automotive, “bulkhead bolts” usually means close-tolerance structural bolts (e.g., AN/NAS/Hi-Lok class) that join bulkhead frames or brackets. Here the focus is precise fit, proper preload, and vibration resistance, typically with locknuts, collars, or safetying.

Key points: there’s no special thread form or universal head for a “bulkhead bolt”—material, head style, and length are selected for the structure and environment. Good practice is to use backing plates, anti-vibration locking (nylon-insert or all-metal lock nuts), isolate dissimilar metals to prevent galvanic corrosion, and seal any penetrations that must remain weather- or watertight.

Burst