Resources

Glossary

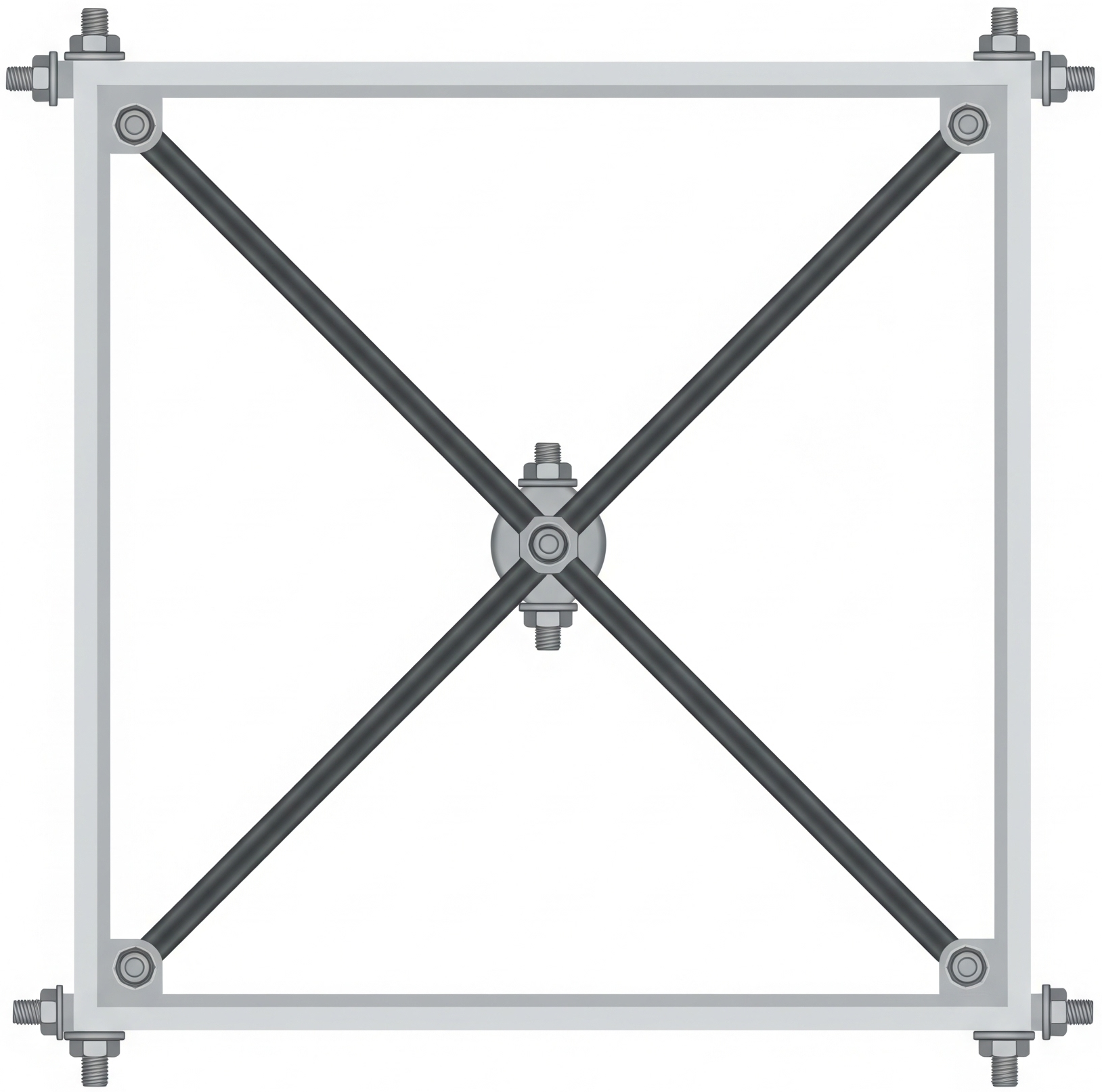

X-Brace / Cross Brace

An X-brace, also called a cross brace, is a structural reinforcement made by installing two diagonal members that cross each other in the shape of an “X.” This type of bracing is widely used in construction, engineering, and machinery to provide lateral stability and prevent racking (side-to-side movement).

In fasteners and assemblies, X-bracing ensures that loads are distributed more evenly and that structures resist twisting or collapsing under stress. The crossing members are typically connected at their intersection and anchored at the frame corners with bolts, rivets, or welds.

Steel buildings and bridges to resist wind and seismic forces.

Scaffolding and towers for stability under vertical and lateral loads.

Furniture, shelving, and frames to prevent wobbling or leaning.

Mechanical assemblies and equipment where vibration resistance is needed.

Xenon Arc Testing

Xenon arc testing is a type of accelerated weathering test used to evaluate how materials—such as coatings, paints, plastics, adhesives, and sometimes fastener finishes—will withstand long-term exposure to sunlight, heat, and moisture. In this method, a xenon arc lamp simulates the full spectrum of natural sunlight, including ultraviolet (UV), visible, and infrared radiation.

Test samples are placed in a chamber where they are exposed to intense light, controlled humidity, and sometimes water spray or temperature cycles. This environment reproduces years of outdoor weathering in a much shorter time, allowing manufacturers to assess fading, discoloration, cracking, chalking, loss of gloss, and corrosion resistance.

Xylan® Coating

A fluoropolymer coating (brand name by Whitford) commonly applied to fasteners for low friction, corrosion resistance, and chemical resistance. Often used in oil & gas, marine, and automotive.