Resources

Glossary

V-Bolt

A V-bolt is a fastener with a V-shaped body and threads on both ends, designed specifically to clamp objects with angled or V-shaped profiles. Unlike the round or square shapes of a U-bolt, the V-bolt's design allows it to fit snugly over a triangular or angled surface, such as a structural beam or a bracket. It works by having its threaded legs pass through a mounting plate, with nuts then tightened to create a strong clamping force that secures the object in place and prevents it from slipping.

This specialized shape makes V-bolts an excellent choice for a variety of applications, particularly those involving mounting and bracing on angled surfaces. They are widely used in construction, for securing components to structures with V-shaped tops, and in telecommunications for mounting antennas and masts to poles. Their ability to provide a secure, non-slip grip on angled components makes them a reliable and versatile fastener in many industries.

Vanadium (V)

Vanadium is a hard, silvery-gray metallic element with the chemical symbol V and atomic number 23. It’s a transition metal valued for its high strength, corrosion resistance, and ability to improve the properties of alloys, especially steel. Though relatively rare in pure form, vanadium plays a crucial role in metallurgy, chemical manufacturing, and energy storage technologies.

In its pure state, vanadium is ductile, malleable, and nonmagnetic, with a high melting point of 1,910°C (3,470°F). It naturally forms a thin oxide layer that protects it from corrosion, much like aluminum and titanium. Because of this, vanadium and its alloys are used in environments where materials must endure heat, stress, and oxidation—such as aerospace structures, jet engines, and turbine blades.

The majority of vanadium produced worldwide—about 80–90%—is used in the steel industry. When added in small amounts (typically less than 0.2%), vanadium significantly increases tensile strength, wear resistance, and fatigue life. Steels alloyed with vanadium, known as vanadium steels, are used in tools, springs, pipelines, automotive components, and structural beams. High-speed steels and chromium-vanadium (Cr-V) tools are particularly common examples, prized for their toughness and resistance to deformation.

Beyond steelmaking, vanadium is also a key element in aerospace-grade titanium alloys, where it enhances high-temperature stability and tensile strength. Alloys like Ti-6Al-4V (90% titanium, 6% aluminum, 4% vanadium) are the standard materials for aircraft frames, jet engines, and medical implants.

In the chemical industry, vanadium compounds—especially vanadium pentoxide (V₂O₅)—are used as catalysts in the production of sulfuric acid, one of the world’s most important industrial chemicals. Vanadium is also gaining attention in the field of renewable energy, particularly in vanadium redox flow batteries (VRFBs), which store large amounts of energy for grid-scale applications due to their long lifespan and high efficiency.

Vanadium is primarily obtained from vanadinite (Pb₅(VO₄)₃Cl), patronite (VS₄), and magnetite (Fe₃O₄) ores containing vanadium impurities. Major producers include China, Russia, South Africa, and Brazil.

Vanadium Pentoxide (V₂O₅)

Vanadium Pentoxide (V₂O₅) is a bright yellow to rust-orange crystalline compound composed of vanadium and oxygen, and it is one of the most important industrial compounds of vanadium. Chemically, it serves as both an oxidizing agent and a catalyst, making it indispensable in metal production and chemical manufacturing.

In its solid form, vanadium pentoxide consists of layers of vanadium atoms surrounded by oxygen atoms in a distorted octahedral arrangement. It is amphoteric, meaning it can react with both acids and bases, and it exhibits multiple oxidation states, allowing it to easily gain or lose oxygen in chemical reactions. This redox flexibility is what makes V₂O₅ such a powerful catalyst.

The compound’s most important industrial use is as a catalyst in the Contact Process, which produces sulfuric acid—one of the world’s most heavily produced chemicals. In this process, V₂O₅ facilitates the conversion of sulfur dioxide (SO₂) to sulfur trioxide (SO₃) by transferring oxygen atoms efficiently. It’s also used in the manufacture of maleic anhydride, phthalic anhydride, and other organic intermediates.

In metallurgy, vanadium pentoxide is used to produce ferrovanadium alloys, which strengthen steel and improve resistance to heat and wear. When mixed with other metals, it imparts high tensile strength and fatigue resistance—qualities essential for aerospace components, tools, and high-performance steel.

V₂O₅ is also used in ceramics, glass, and pigments, where it acts as a colorant that gives yellow, green, or blue hues depending on oxidation conditions. In electronics and emerging energy technologies, it’s used in vanadium redox flow batteries and solid-state devices because of its ability to reversibly store and release oxygen ions.

However, vanadium pentoxide is toxic in dust or fume form. Inhalation or prolonged exposure can irritate the respiratory tract and cause health issues, so industrial handling requires proper ventilation and protective equipment.

Vented Screw

A vented screw, also known as a vacuum or hollow screw, is a specialized fastener with a hole drilled through its center along its entire length. Its primary purpose is to eliminate "virtual leaks," which are pockets of trapped air and gas that can compromise a vacuum system. When a regular screw is used in a blind-tapped hole (one that doesn't go all the way through a material), air gets sealed in, which then slowly leaks out. The central hole of a vented screw provides a clear path for this trapped air to escape, allowing a vacuum chamber to be pumped down more quickly and completely.

This unique design makes vented screws essential in applications where a high-quality vacuum is critical. They are commonly used in scientific and medical equipment, semiconductor manufacturing, and aerospace systems where a clean, sealed, and pressure-regulated environment is required. By ensuring that no air is trapped, vented screws help maintain the integrity and performance of the vacuum.

Vernier Caliper

A vernier caliper is a precision measuring instrument used to determine the exact dimensions of an object—such as length, diameter, thickness, or depth—with high accuracy. It consists of a main scale and a sliding vernier scale that work together to provide readings typically accurate to 0.02 mm (0.001 inch) or better.

The instrument features two sets of jaws: the larger jaws measure external dimensions (like the outer diameter of a bolt or shaft), and the smaller jaws measure internal dimensions (such as the inside diameter of a hole). Many models also include a depth probe that extends from the end of the caliper to measure the depth of holes, slots, or recesses.

The principle behind the vernier caliper is the Vernier scale, a secondary scale that allows the user to read between the smallest divisions on the main scale. By aligning the vernier scale marks with those on the main scale, the user can determine fractional measurements with very fine precision.

Vernier calipers are widely used in manufacturing, machining, mechanical engineering, metalworking, and quality control because they provide a reliable and versatile way to measure components without relying on electronic devices.

Vibration-Damping Mount

A vibration-damping mount (also called an anti-vibration mount or vibration isolator) is a mechanical component designed to absorb and reduce the transmission of vibration and shock between two connected parts—typically machinery and its supporting structure. These mounts are made from elastic materials such as rubber, neoprene, silicone, or specialized polymers that deform under dynamic loads to dissipate vibrational energy as heat.

When machinery operates—such as motors, compressors, pumps, or fans—it generates vibrations that can travel through its mounting points into the surrounding structure. Over time, this can lead to noise, wear, fatigue damage, and alignment issues. Vibration-damping mounts act as cushions or isolators that decouple the vibrating source from its base, protecting both the machine and the structure from these effects.

They come in many forms, including cylindrical mounts, sandwich mounts, conical mounts, and bonded rubber-metal assemblies, each designed to handle specific load directions and frequencies. Some advanced versions combine rubber elements with metal springs or hydraulic chambers to achieve better control over damping across a wide frequency range.

Vibratory Loosening

Vibratory loosening is the self-unscrewing of a threaded fastener like a bolt or screw due to vibrations. It's a progressive, two-step process: first, vibration causes microscopic movements within the joint, leading to a loss of the initial clamping force, or preload. Once that preload is weakened, any continued vibration can cause the fastener to gradually rotate, leading to a complete failure of the joint.

To prevent vibratory loosening, engineers use various methods to ensure the fastener remains secure. These include mechanical locking devices such as lock nuts, lock washers (like wedge-locking washers), and cotter pins that physically stop the fastener from rotating. Chemical solutions like threadlockers (adhesives that fill the gaps in threads) are also used. Most importantly, proper joint design and tightening the fastener to its correct preload are crucial, as a strong initial clamp is the best defense against this common cause of mechanical failure.

Vickers Hardness Test

Vickers Hardness (HV) is a measure of a material’s hardness determined using the Vickers hardness test. In this test, a diamond-shaped pyramid indenter is pressed into the material’s surface under a specific load. The size of the indentation left behind is measured under a microscope, and the hardness value (HV) is calculated based on the applied force divided by the surface area of the indentation.

This method is widely used because it can test very hard or very thin materials, and it works on metals, ceramics, and coatings. Vickers Hardness is expressed in units of HV (e.g., 450 HV), where higher numbers indicate harder materials. It’s commonly applied in metallurgy, fastener testing, aerospace, and quality control to evaluate wear resistance, strength, and material performance.

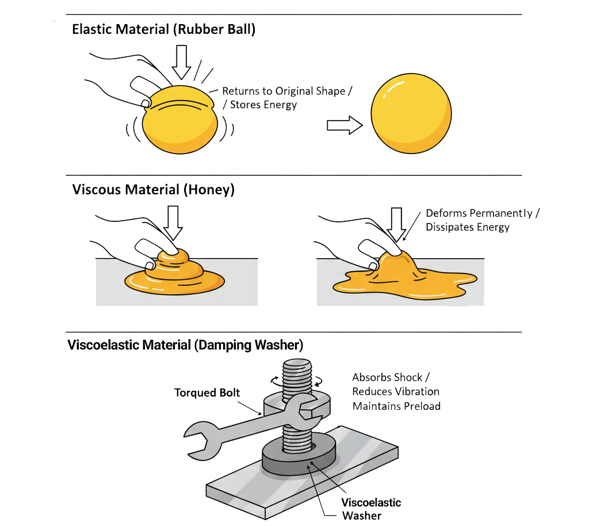

Viscoelasticity

Viscoelasticity is a material property that describes how a substance exhibits both viscous and elastic behavior when subjected to deformation.

A viscous material (like honey or oil) resists flow and dissipates energy as heat, meaning it deforms continuously under stress and doesn’t return to its original shape once the stress is removed. An elastic material (like rubber) deforms under stress but stores that energy and returns to its original form once the stress is gone.

A viscoelastic material combines these two behaviors. When a force is applied, it both deforms elastically (storing energy) and flows or relaxes over time (dissipating energy). When the force is removed, it gradually returns toward its original shape but may not recover instantly or completely.

This property is common in materials such as rubber, polymers, biological tissues, and damping materials, which are often used in fasteners and vibration-control applications. In fasteners, viscoelastic components—like damping washers or polymer seals—help absorb shocks, reduce vibration, and maintain preload stability by controlling how stress and strain are distributed over time.

Viscosity

When referring to fasteners, viscosity usually comes up in the context of lubricants, coatings, or adhesives used with them.

Viscosity is the measure of a fluid’s resistance to flow. In fasteners, it matters because the thickness or flow characteristics of oils, greases, thread-locking compounds, or anti-seize coatings directly affect installation, torque, and long-term performance.

Lubrication & Torque: A high-viscosity lubricant (thicker) may stay in place better but can reduce accuracy in torque-tension relationships. Low-viscosity lubricants (thinner) spread more easily, reducing friction more consistently.

Threadlockers & Adhesives: Anaerobic adhesives like Loctite® are formulated with different viscosities—low-viscosity grades wick into pre-assembled threads, while high-viscosity grades fill gaps in looser assemblies.

Coatings & Corrosion Protection: The viscosity of protective coatings affects how evenly they cover a fastener and how well they resist dripping or running during application.

In short, viscosity determines how lubricants and adhesives behave on fastener threads, which directly influences torque, preload, and resistance to loosening.

Vulcanization

Vulcanization is a chemical process used to strengthen rubber by adding sulfur (or other curatives) and applying heat. This process forms cross-links between the long molecular chains of raw rubber, transforming it from a sticky, soft material into one that is more durable, elastic, and resistant to heat, wear, and aging.

For fasteners and industrial uses, vulcanization is important in the production of rubber washers, seals, gaskets, O-rings, and vibration-damping components. Without vulcanization, natural rubber would deform easily, lose strength, and degrade quickly. With it, rubber parts can maintain consistent performance under mechanical stress, temperature changes, and chemical exposure.