Resources

Glossary

Dacromet®

Dacromet coating is a type of water-based, inorganic protective coating widely used to prevent corrosion on metal parts, especially fasteners such as bolts, nuts, and washers. It is a thin, silvery-gray coating made primarily of zinc and aluminum flakes dispersed in a chromium oxide binder. When applied and baked onto a metal surface, these overlapping flakes form a dense, plate-like barrier that shields the substrate from oxygen, moisture, and corrosive agents.

The coating works in two main ways. First, it provides a barrier effect, where the tightly packed zinc and aluminum flakes physically block corrosive substances from reaching the base metal. Second, it provides cathodic protection, since the zinc in the coating is more electrochemically active than steel and sacrifices itself to protect the underlying substrate. Unlike traditional paints, which rely solely on surface sealing, Dacromet combines both sacrificial and barrier mechanisms, making it highly effective in aggressive environments.

One of its major advantages is that it offers excellent corrosion resistance while applying a very thin film, typically only 4–8 microns thick. This allows fasteners to maintain their dimensions and thread tolerances without the buildup seen in hot-dip galvanizing. It also resists hydrogen embrittlement, which is a risk in electroplated coatings, making it suitable for high-strength bolts and critical structural fasteners. Additionally, Dacromet coatings can withstand high temperatures and provide uniform coverage even on complex geometries, including recessed areas and threads.

Dacromet has been widely adopted in the automotive, construction, and industrial sectors for applications requiring long-term corrosion resistance, such as brake components, chassis fasteners, wind turbines, and outdoor structural steel. However, because it contains hexavalent chromium, environmental and health regulations have led to restrictions and the development of alternatives like Geomet coatings, which offer similar performance without the use of toxic chromium compounds.

Damascus Steel

Damascus steel is a legendary type of steel that was historically used to make blades, swords, and knives, most famously from around the 3rd to the 17th century in the Middle East and surrounding regions. Its name comes from either the city of Damascus in Syria, a major trade hub for these blades, or from the Arabic word damas (meaning "watered"), which describes the flowing, wave-like surface patterns seen on the steel.

The steel is famous for its distinctive banded or wavy patterns that look like running water or wood grain. These patterns were not just decorative; they resulted from the way the metal was forged. True Damascus steel was produced using wootz steel imported from India and Sri Lanka, which contained trace impurities of vanadium and other elements. Blacksmiths forged and folded this steel in a way that preserved its unique crystalline microstructure, giving the blades a combination of extreme hardness and toughness—hard enough to hold a sharp edge, but flexible enough to resist shattering. These properties made Damascus steel weapons highly prized, with legends claiming they could slice through other swords or even cut a hair falling on the blade.

By the 18th century, the original process for making true Damascus steel was lost, largely because the supply of wootz ingots from India dried up and the exact methods were closely guarded secrets never fully documented. Modern bladesmiths today recreate “Damascus” steel through pattern welding, which involves forge-welding layers of different steels together and manipulating them to form the same kind of flowing patterns. While this modern Damascus often equals or exceeds the performance of the historical material thanks to advances in metallurgy, it is not identical to the ancient wootz-based steel.

Damping Washer

A damping washer is a specialized washer designed to absorb vibration, reduce noise, and minimize loosening in bolted joints. Unlike standard flat washers that simply distribute load, damping washers incorporate elastic or viscoelastic materials—such as rubber, silicone, or engineered polymers—that deform under pressure and dissipate mechanical energy as heat.

When installed between the fastener head (or nut) and the mating surface, the washer compresses slightly. This compression helps to absorb shocks, dampen resonant vibrations, and maintain preload stability even under dynamic conditions. In many designs, a metal washer is bonded to a rubber or elastomeric layer to combine strength and flexibility.

Damping washers are commonly used in automotive assemblies, aerospace components, industrial machinery, and electronic enclosures, where vibration and noise can cause fatigue, loosening, or damage over time.

Dead Load

Dead load refers to the permanent, static weight of a structure or object — the weight that remains constant over time and does not change during normal operation. It includes all the fixed components of a structure, such as beams, columns, walls, floors, roofing, fasteners, and any permanently attached fixtures or equipment.

In engineering terms, dead load represents the self-weight of the structure — the gravitational force exerted by the materials from which the structure is built. For example, in a bridge, the dead load includes the deck, supports, and any permanently installed utilities. In a building, it includes the framework, flooring systems, roofing materials, and built-in features.

Dead load is measured in units of force (such as newtons or pounds-force) or weight per unit area (such as kN/m² or psf) and is a critical factor in structural design. Engineers use it to calculate the total load-bearing capacity and to ensure that foundations, supports, and fasteners can safely handle both the dead load and additional live loads — which are temporary or variable forces such as vehicles, people, wind, or snow.

Deburr

The process of removing sharp edges, burrs, or rough spots left on a fastener after manufacturing or machining. Deburring improves safety, fit, and function by creating smooth surfaces and preventing damage during assembly.

Decarburization

Decarburization is the loss or removal of carbon from the surface layer of steel or iron when it is exposed to a high-temperature environment containing oxygen, hydrogen, or other reactive gases. This process alters the metal’s chemical composition near the surface, reducing the carbon content and, as a result, lowering its hardness, strength, and wear resistance.

During heat treatment, forging, or annealing, if steel is not properly protected, the carbon atoms at the surface react with oxygen or water vapor in the furnace atmosphere to form carbon monoxide (CO) or carbon dioxide (CO₂). As these gases escape, they deplete the surface of carbon, creating a softer, weaker layer while the inner core retains its original carbon content and mechanical properties.

Decarburization can occur in two forms: partial, where only a portion of the surface is affected, and complete, where all carbon near the surface is lost. The depth of decarburization depends on factors like temperature, exposure time, and atmosphere composition.

In engineering, decarburization is undesirable because it can lead to reduced fatigue strength, poor wear resistance, and premature failure in components such as bolts, gears, springs, and shafts. To prevent it, manufacturers use controlled-atmosphere furnaces, vacuum heat treatment, or protective coatings to maintain carbon stability during processing.

Deck Screw

A deck screw is a type of fastener specifically designed for outdoor wooden construction, most commonly used in building decks, fences, and other exterior structures. Unlike general-purpose wood screws, deck screws are engineered to withstand weather exposure and resist corrosion, ensuring long-term durability in outdoor environments where moisture, temperature changes, and UV exposure can cause ordinary screws to fail.

Deck screws are usually made from steel and then coated or treated to improve corrosion resistance. Common finishes include galvanized coatings, ceramic coatings, epoxy coatings, or stainless steel, with stainless being the most resistant in harsh environments such as coastal areas. Their design often features sharp, deep threads that bite into wood fibers securely, providing strong holding power and reducing the chance of wood splitting.

The head of a deck screw is typically a flat, countersunk design so that it sits flush with or just below the wood surface, preventing snags and giving a clean finish. Many deck screws also include a self-countersinking feature with small cutting ridges under the head to help them sink smoothly into wood without pre-drilling. The drive style is most often Phillips, square (Robertson), or star/Torx, which help reduce cam-out and allow greater torque to be applied during installation.

Because of their specialized design, deck screws are a critical choice for structural integrity and longevity in outdoor projects. Using the wrong type of screw, such as untreated interior wood screws, can lead to rust, staining of the wood, and eventual structural failure of the deck or fence.

Decorative Bolt

A decorative bolt is a type of fastener designed not only for function but also for aesthetic appeal. Unlike standard bolts that prioritize strength and load-bearing capacity, decorative bolts are often used where appearance matters as much as performance—such as in architectural, furniture, automotive, or ornamental metalwork applications.

These bolts may have polished, plated, or textured finishes like chrome, brass, stainless steel, or black oxide, giving them a refined or custom look. The heads can be shaped or stylized—featuring domed, flanged, slotted, or even custom-designed tops that complement the surrounding design. In some cases, decorative bolts conceal the functional parts of a joint, blending seamlessly into the overall visual design.

While they still provide fastening strength, decorative bolts are typically used in low- to moderate-load applications, such as securing panels, trim, furniture hardware, or visible machine components. The key focus is achieving both durability and visual harmony with the product’s design.

Delta Protekt®

A family of engineered coating systems developed by Magni Industries, designed to protect fasteners and metal components against corrosion. Magni® coatings often combine an inorganic zinc-flake basecoat with an organic topcoat, offering customizable friction properties, color options, and high salt-spray resistance for automotive, construction, and heavy-equipment applications.

Demountable Nut

A demountable nut is a type of fastener nut designed to be easily removed and reattached, typically used in applications where frequent assembly and disassembly are required. Unlike conventional nuts, which are often tightened to a fixed torque and may deform or seize under repeated use, demountable nuts are engineered for reusability and convenience without compromising strength or reliability.

These nuts often incorporate special features that allow them to maintain a secure hold while still being removable. For example, some designs use a split body, spring action, or captive insert that grips the bolt threads firmly during service but can be released when the nut is turned in the opposite direction. Others may be designed to snap into place or engage with mating hardware in a way that does not damage the threads during tightening or loosening.

Demountable nuts are commonly used in industries where parts need to be serviced or replaced frequently, such as automotive, aerospace, railway systems, heavy machinery, and modular structures. Their biggest advantage is reducing maintenance time while ensuring that assemblies remain secure under load and vibration.

Derlin Fastener

A Delrin fastener is a fastening component—such as a screw, nut, bolt, or washer—manufactured from Delrin®, which is the trade name for polyoxymethylene (POM), an acetal homopolymer plastic developed by DuPont. Delrin is known for its excellent combination of strength, stiffness, low friction, and wear resistance, making it a popular choice when metal fasteners are unnecessary or undesirable.

Delrin fasteners are lightweight, non-magnetic, and resistant to moisture, solvents, fuels, and many chemicals. Unlike metals, they will not corrode or rust, and they offer electrical insulation properties, which is critical in electronics and sensitive equipment. While not as strong as steel, Delrin fasteners provide good tensile strength and dimensional stability for many engineering applications.

These fasteners are commonly used in environments where metal fasteners would cause problems, such as electrical assemblies, medical devices, aerospace components, laboratory equipment, chemical processing systems, and marine or outdoor applications. Their low coefficient of friction also makes them ideal for moving parts where smooth operation and reduced wear are important.

However, Delrin fasteners are not recommended for very high-temperature or extremely high-load applications, as plastics can soften or creep under sustained stress. Engineers often select Delrin when they need a balance of lightweight, corrosion resistance, chemical resistance, and mechanical reliability without the conductivity or weight of metal.

DFARS Compliance

The Defense Federal Acquisition Regulation Supplement (DFARS) outlines sourcing requirements for materials and products used in U.S. Department of Defense contracts. In the case of fasteners, DFARS compliance means that certain items made from specialty metals such as alloy steels, nickel or cobalt-based alloys, titanium, or zirconium must be both melted and manufactured in the United States or in an approved qualifying country. Compliance ensures fasteners meet government standards and are eligible for military and defense applications.

Blog Post: What Does DFARS Compliant Mean for Fastener Suppliers?

Diameter

The measurement of a fastener’s width, typically taken across the shank for bolts and screws, or across the internal threaded opening for nuts. Diameter determines the correct hole size for a fastener and ensures compatibility between mating parts.

Die

An industrial die is a specialized tool used in manufacturing to shape, cut, or form material—most often metal—into precise and repeatable geometries. Dies are essential in mass production because they allow manufacturers to produce large quantities of identical components with high accuracy.

Dies work by being mounted in presses or machines where material is forced into, through, or against the die cavity or cutting edge. The material takes on the shape defined by the die. Depending on the process, dies can cut material (as in stamping or punching), shape it (as in extrusion or forging), or form threads (as in thread-cutting dies for screws and bolts).

There are several major types of industrial dies. Cutting dies are used to shear or punch material into a desired outline, such as sheet metal parts. Forming dies bend or stretch material into specific contours. Extrusion dies push heated material through a die opening to create continuous shapes like pipes, rods, or profiles. Forging dies shape hot metal into complex parts by compressive force. Threading dies cut external threads on fasteners, while molding dies shape materials like plastics or composites.

Industrial dies are typically made from hardened tool steels or carbides because they must withstand extreme pressures, wear, and repeated cycles. Their design is a critical part of manufacturing engineering, since the accuracy of the die directly determines the accuracy of the finished product.

Die Casting

Die casting is a manufacturing process used to produce metal parts by forcing molten metal under high pressure into a mold cavity, known as a die. The die is typically made of hardened tool steel and designed in two halves that form the shape of the part when closed. Once the molten metal—commonly aluminum, zinc, or magnesium—is injected and solidifies, the die is opened, and the finished part is ejected.

This process allows for high-volume production of parts with excellent dimensional accuracy, fine surface finish, and complex geometries that would be difficult or expensive to achieve with machining or other casting methods. Because the molten metal cools quickly under pressure, die-cast parts often have a dense, strong structure with tight tolerances and thin walls.

There are two main types of die casting: hot chamber and cold chamber. Hot chamber die casting is used for metals with lower melting points (like zinc or magnesium) and involves immersing the injection mechanism directly in the molten metal. Cold chamber die casting, used for higher-melting-point metals such as aluminum, requires the molten metal to be ladled into a separate chamber before being injected into the die.

Die casting is commonly used in industries such as automotive, aerospace, electronics, and consumer products to create components like engine housings, brackets, handles, and enclosures—offering a balance of precision, strength, and cost-efficiency.

Dielectric Fastener

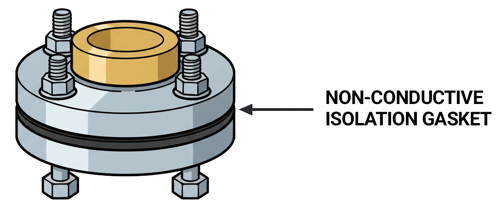

A dielectric fastener is a type of fastening component made from non-conductive materials that provide both mechanical fastening and electrical insulation. Unlike metal fasteners, which can conduct electricity and create pathways for current, dielectric fasteners are designed specifically to prevent electrical conduction between joined components.

These fasteners are typically manufactured from high-performance plastics, composites, or ceramics with excellent insulating properties. Common materials include nylon, PTFE (Teflon), acetal, phenolic resins, fiberglass-reinforced polymers, or engineered ceramics. In addition to electrical insulation, many dielectric fasteners are resistant to corrosion, chemicals, and moisture, making them suitable for harsh environments.

Dielectric fasteners are widely used in industries such as electronics, aerospace, telecommunications, and power systems, where maintaining electrical isolation is critical. They are often used to mount circuit boards, secure electrical enclosures, or join materials in assemblies where stray currents, arcing, or galvanic corrosion could cause failure.

Beyond insulation, dielectric fasteners can also reduce weight compared to metal hardware, which is especially valuable in aerospace and high-performance applications. However, their strength is typically lower than that of steel or other metals, so they are used where electrical and chemical properties are more important than high mechanical loads.

Differential Bolt

A differential bolt is a specialized fastener used to secure the differential assembly—the gear housing that allows drive wheels to rotate at different speeds—within a vehicle’s drivetrain. These bolts are engineered to handle significant torsional and shear stresses, as the differential experiences heavy loads during acceleration, cornering, and torque transfer between axles.

In most cases, the term “differential bolt” can refer to one of several specific uses within the differential system:

Ring Gear Bolts: These secure the ring gear to the differential carrier. They must resist rotational forces and are typically high-strength, fine-threaded fasteners with precise torque specifications. They are often treated with threadlocker compounds or safety wire to prevent loosening under vibration.

Carrier or Bearing Cap Bolts: These fasten the differential carrier bearings to the axle housing. They maintain bearing preload and alignment—critical for quiet, smooth operation.

Pinion Shaft (Cross Shaft) Bolts: These hold the spider gear pinion shaft inside the carrier. Because this bolt endures repeated rotational shock loads, failures here can cause catastrophic differential damage, so they are often hardened or made from alloy steel.

Differential Cover Bolts: These smaller bolts seal the differential cover to the housing, containing the lubricant inside.

Differential bolts are usually grade 8 or higher, made from hardened alloy steel or chromoly, and can be zinc-plated, phosphate-coated, or black oxide finished for corrosion protection. In performance or heavy-duty applications (like racing or off-road vehicles), ARP differential bolts or similar high-strength upgrades are often used to prevent stretching or shearing.

Differential Cover Bolt

A differential cover bolt is a fastener used to secure the differential cover—the metal or aluminum plate that seals the rear of a differential housing. This cover protects the internal components of the differential, including the ring and pinion gears, spider gears, and bearings, while keeping the gear oil contained inside the housing to ensure proper lubrication and cooling. The bolts hold the cover tightly against the differential housing flange, compressing a gasket or RTV sealant to form a leak-proof seal. Because the differential experiences heat, vibration, and torque as the gears operate, these bolts are engineered to deliver precise and consistent clamping force without stripping threads or distorting the cover.

Differential cover bolts are typically small to medium-sized hex-head fasteners, commonly 5/16", 3/8", M8, or M10 depending on the axle type. They are usually made from hardened steel, often graded as SAE Grade 8 or metric Class 10.9, providing the strength and durability required for this high-stress environment. The bolts are frequently finished with zinc plating, phosphate coating, or black oxide to resist corrosion caused by gear oil, road salt, and environmental exposure. Many versions use flanged heads or washers to evenly distribute the clamping load and maintain a tight seal. To prevent loosening from vibration, manufacturers often recommend applying threadlocker, while anti-seize compound may be used in cases where corrosion could make future removal difficult.

When installing or replacing differential cover bolts, proper torque application and sequence are critical. The bolts must be tightened in a crisscross pattern to apply even pressure across the gasket or sealant, ensuring a uniform seal. Torque specifications vary by axle model but generally fall between 20 and 35 ft-lb. Over-tightening can warp the cover or strip the housing threads, which would lead to oil leaks and potentially expensive repairs. If a gasket or RTV silicone sealant is used, it must be allowed to cure according to manufacturer specifications before final torqueing to achieve an optimal seal.

Differential cover bolts are used in nearly every automotive axle assembly, from passenger vehicles and pickup trucks to heavy-duty commercial and off-road applications. In performance and racing vehicles, stainless steel or ARP high-strength versions are sometimes used for their resistance to corrosion and their ability to hold torque accurately under extreme conditions. Though small in size, differential cover bolts play an essential role in maintaining the integrity of the differential assembly by ensuring that the cover remains securely sealed, preventing fluid leaks, keeping out dirt and debris, and allowing the gears and bearings inside to operate smoothly and reliably over time.

Diffusion Hardening

Diffusion hardening is a heat treatment process used to improve the surface hardness and wear resistance of metals by introducing specific elements into the outer layer of the material through diffusion. Unlike processes that simply heat and quench the entire part, diffusion hardening alters only the surface composition while leaving the core relatively tough and ductile.

The process works by heating the metal—usually steel or other alloys—to a temperature at which atomic diffusion is active. Elements such as carbon, nitrogen, or boron are introduced in a controlled environment, and these atoms diffuse into the surface of the metal. This creates a hardened outer layer with enhanced properties, while the interior remains softer and more shock-absorbing.

There are several well-known diffusion hardening techniques. Carburizing introduces carbon into the surface, commonly used for gears and shafts. Nitriding introduces nitrogen, producing a very hard and wear-resistant surface without requiring quenching. Carbonitriding combines both carbon and nitrogen for additional strength, while boriding introduces boron for extreme hardness and wear resistance.

The main advantage of diffusion hardening is that it improves a part’s surface performance—resisting wear, fatigue, and surface damage—without sacrificing the toughness of the core. This makes it ideal for components such as gears, bearings, fasteners, and machine parts that experience surface stresses but also need to withstand impact loads.

Digital Torque Wrench

A digital torque wrench is a precision tool used to measure and apply a specific amount of torque to a fastener—such as a bolt or nut—while providing real-time electronic feedback. Unlike traditional click or beam-type torque wrenches, a digital torque wrench uses electronic sensors (typically strain gauges) to detect the applied torque and display it on an LCD or LED screen, often in multiple units (Nm, ft-lb, in-lb).

These tools ensure that fasteners are tightened to the exact specification required—critical in industries like automotive, aerospace, energy, and precision manufacturing, where incorrect torque can lead to equipment failure or safety risks.

Many digital torque wrenches feature audible, visual, or vibrational alerts that notify the user when the target torque value is reached, improving accuracy and repeatability. Advanced models also include data logging, wireless connectivity (Bluetooth or USB), and programmable torque settings, allowing for digital recordkeeping and quality assurance in production environments.

Dimpling

Dimpling is a sheet metal process used to form a shallow, conical recess that allows a countersunk fastener, such as a flush rivet or screw, to sit level with the surface. Instead of removing material like a drilled countersink, dimpling reshapes the sheet by pressing it into a die, which preserves more of the material’s strength while still creating space for the fastener head.

This technique is widely used in aerospace, automotive, and electronics applications where smooth, aerodynamic, or snag-free surfaces are required. It provides both functional and aesthetic benefits by allowing flush fastening without compromising the integrity of thin sheet materials.

DIN

DIN in fasteners refers to the Deutsches Institut für Normung, or the German Institute for Standardization. A fastener labeled with a DIN designation (such as DIN 933 hex bolt or DIN 912 socket head cap screw) indicates it was manufactured to a specific German national standard. These standards define the dimensions, tolerances, materials, finishes, and mechanical properties of the fastener, ensuring consistency and interchangeability across manufacturers. Although DIN standards originated in Germany, they have been widely adopted globally and remain a common reference point in engineering, manufacturing, and distribution.

Many DIN fasteners now have direct ISO (International Organization for Standardization) or EN (European Norm) equivalents, but the DIN numbers are still heavily used, especially in engineering drawings, machinery designs, ordering systems, and catalogs. For example, DIN 933 corresponds to a hexagon head bolt with a full thread, DIN 934 specifies a hexagon nut, and DIN 125 covers flat washers. While ISO and EN standards have become the international norm, DIN remains prevalent in legacy designs and German machinery, and it continues to play an important role in global trade.

DIN 931

DIN 931 is a German and international standard established by the Deutsches Institut für Normung that defines the dimensions, mechanical properties, and tolerances for partially threaded hex head bolts and screws with metric threads. These bolts are widely recognized for their precision and reliability, making them a fundamental component in engineering and manufacturing across industries.

DIN 931 bolts are among the most common fasteners used in machinery, construction, and general engineering applications. Each bolt features a hexagonal head and a partially threaded shank, meaning that only part of the bolt’s length is threaded while the remaining section is a smooth, unthreaded portion known as the grip length. This combination allows for strong clamping forces while minimizing shear stress on the threaded section.

They are designed with metric coarse threads per ISO 261/965 and typically feature a hex head following the DIN EN ISO 4014 standard, which has largely replaced DIN 931 in modern international use. The length of threading varies depending on the overall bolt length, with shorter bolts having a greater percentage of threading. These fasteners are generally made from high-strength steel grades such as 8.8, 10.9, or 12.9, although stainless steel and brass variants are also common for corrosion resistance or decorative use. Finishes include zinc plating, black oxide, hot-dip galvanization, or a plain uncoated surface, depending on the environment and application.

DIN 931 is closely related to other standards, including ISO 4014, which has effectively replaced it as the global equivalent for metric hex bolts. It also compares to DIN 933 or ISO 4017, which describe fully threaded hex bolts, and to ANSI/ASME B18.2.1, the U.S. inch-series counterpart.

These bolts are used extensively in mechanical assemblies, automotive manufacturing, structural steelwork, and equipment housings. Their partial threading makes them ideal for applications requiring high clamping strength and precise alignment, ensuring durability and performance in both static and dynamic load conditions.

DIN 933

DIN 933 is a German and international standard that specifies the dimensions, tolerances, and mechanical properties for fully threaded hex head bolts and screws with metric threads. Like DIN 931, it originates from the Deutsches Institut für Normung (DIN), but the key distinction is that DIN 933 bolts have threads running along the entire length of the shank, from the tip all the way up to the underside of the head.

These bolts are part of the same family as DIN 931 and are among the most widely used fasteners in machinery, engineering, construction, and equipment assembly. The hexagonal head allows for high torque application using standard wrenches or sockets, while the full-length threading provides a secure hold when full engagement of the nut or tapped hole is needed. This makes DIN 933 bolts particularly useful in situations where adjustments, clamping thickness variations, or full-thread engagement are required.

DIN 933 bolts are produced with metric coarse threads (M-thread) in accordance with ISO 261/965 standards. They are typically made from carbon steel or alloy steel in strength grades such as 8.8, 10.9, or 12.9, though stainless steel (A2, A4) and brass versions are also common for corrosion resistance. The surface finish can vary depending on the intended environment and may include zinc plating, black oxide, hot-dip galvanization, or plain uncoated steel.

In terms of modern equivalents, DIN 933 corresponds to ISO 4017, which has largely superseded it in international standards. The key difference between the two lies mainly in dimensional tolerances, which were slightly adjusted to align with ISO metric norms.

DIN 933 bolts are used across a wide range of industries for joining metal components, assembling machinery, securing structural elements, and building equipment housings. Because they are fully threaded, they offer maximum adjustability and grip over the entire length, making them ideal for applications requiring consistent fastening strength, especially in thinner materials or variable stack-ups where the nut must travel along the entire shank.

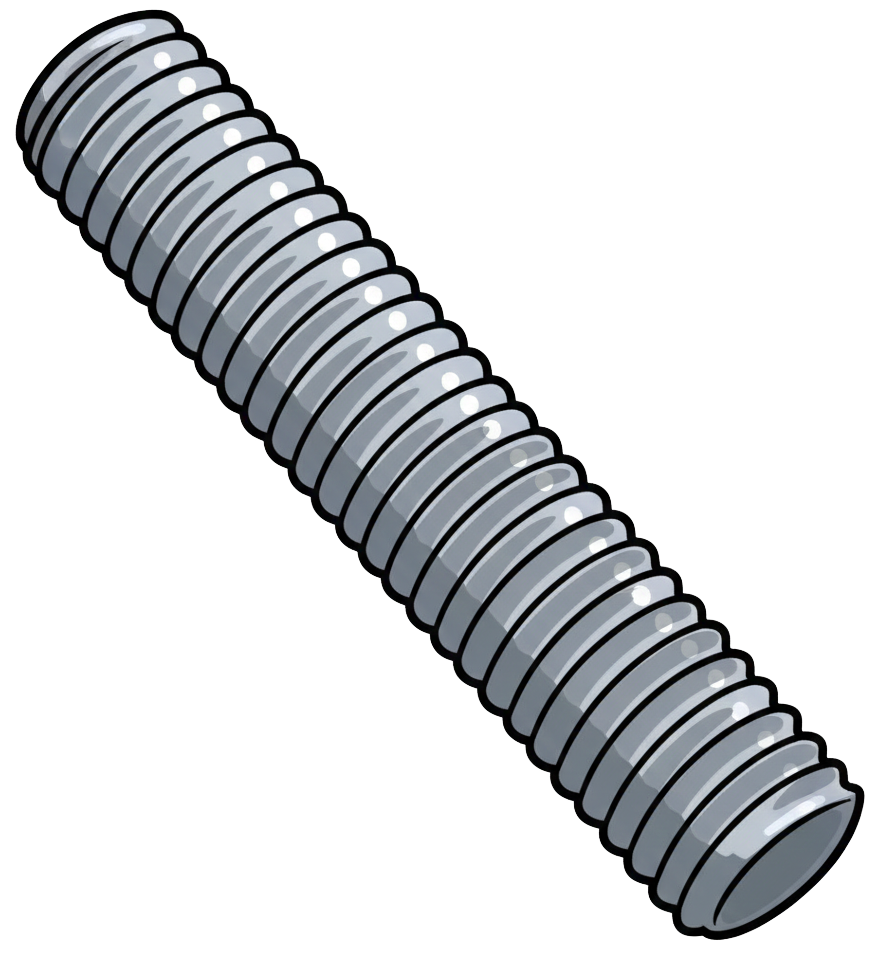

DIN 976-1

DIN 976-1 is a fastener manufacturing standard that covers metric, fully threaded, headless fasteners—commonly sold as threaded rod / all-thread (threaded bar) and fully threaded studs—made with ISO metric external threads and intended to be used with nuts (often on one or both ends) for clamping, anchoring, hanging, and general assembly.

Key identifying features

- Continuous (full) thread along the length (i.e., “all-thread”).

- Often supplied as Shape A threaded bar (commonly noted as the successor to DIN 975).

- Frequently stocked in standard long lengths (commonly 1000 mm, and sometimes 2 m depending on supplier/product form).

Thread/tolerance note (practical shop detail)

- Threaded rod to DIN 976-1 is commonly produced to metric external thread tolerance class 6g. This matters for coatings—e.g., hot-dip galvanized “oversize” threaded rod may require oversize tapped nuts to assemble properly.

Common applications

- Hangers and supports (electrical, plumbing, HVAC)

- Anchoring and mounting equipment and structural components

- Spacers / clamp-up assemblies where you need custom length with nuts and washers

Aspen Fasteners

Related/legacy standard

- DIN 976-1 is widely cited as replacing DIN 975 for threaded rods (you’ll still see “DIN 975” used informally in catalogs).

DIN 976-2

DIN 976-2 is a fastener standard for stud bolts that use a metric interference-fit external thread (often designated MFS) on the end intended to be screwed into light metals (including aluminum). The interference (tight-fit) thread is designed to create a secure, resistant-to-loosening installed stud in softer base materials—functioning like a permanent or semi-permanent stud that accepts a nut on the exposed end.

Key identifying features

- Stud bolt form (headless, used like a stud) with a special interference-fit metric thread (MFS) for the “installed” end.

- Intended for light metal components; not suitable for screwing into steel or cast iron (per the standard’s scope/usage notes).

Common applications

- Creating fixed studs in aluminum/light-alloy housings (machinery, gearboxes, covers, assemblies) where you want better retention than a standard machine thread provides.

Related standard

- Often referenced alongside DIN 976-1, which covers stud bolts with standard metric thread (not interference-fit).

Dip Spin Coatings (Coating)

A non-electrolytic method used to apply a protective or decorative finish to fasteners, especially suitable for bulk application to many small parts. In this process, fasteners are fully submerged (dipped) in a coating solution, then quickly spun in a centrifuge. The spinning action removes excess coating material, resulting in a thin, uniform layer. This technique is highly valued for providing excellent corrosion resistance without the worry or risk of hydrogen embrittlement, which can be a concern with some electroplating processes.

Disc Pad Retaining Bolt

A disc pad retaining bolt is a specialized fastener used in disc brake systems to secure the brake pads within the caliper assembly. Its primary purpose is to hold the pads in precise alignment so they maintain consistent contact with the brake rotor during braking, ensuring even wear, smooth operation, and safety.

Typically found in automotive, motorcycle, and heavy equipment braking systems, these bolts are designed to withstand high temperatures, vibration, and shear forces generated during braking. They are usually made from hardened steel or stainless steel for strength and corrosion resistance, and many include thread-locking compounds or safety clips to prevent loosening from repeated thermal expansion and vibration.

In a disc brake assembly, the retaining bolt passes through the caliper body and the backing plates of the brake pads, locking them in place. When servicing the brakes, these bolts are removed to replace the pads. Because they experience significant mechanical stress, manufacturers often recommend replacing them during maintenance rather than reusing them.

Dislocation Motion

Dislocation motion is the movement of dislocations—defects or irregularities in the atomic structure—within a crystal lattice when a material is subjected to stress. This motion is the primary mechanism by which plastic deformation occurs in metals and crystalline materials.

In a perfect crystal, atoms are arranged in a repeating, orderly pattern. However, real materials contain small imperfections known as dislocations. These are typically line defects, meaning that along a line within the crystal, the arrangement of atoms is slightly displaced. When an external force (such as tension or shear) is applied, the dislocation moves through the crystal, allowing layers of atoms to slip past each other one atomic spacing at a time instead of all at once. This makes deformation much easier and requires far less energy than breaking all atomic bonds simultaneously.

The most common types of dislocations are edge dislocations and screw dislocations. In an edge dislocation, an extra half-plane of atoms is inserted into the lattice, while in a screw dislocation, the crystal layers spiral around the dislocation line like a thread on a screw. As these dislocations move, they cause atoms to shift incrementally, producing permanent (plastic) deformation.

Dislocation motion is influenced by obstacles such as grain boundaries, precipitates, impurities, and other dislocations. Strengthening mechanisms like work hardening, alloying, and heat treatment are designed to impede this movement, making the material stronger but less ductile.

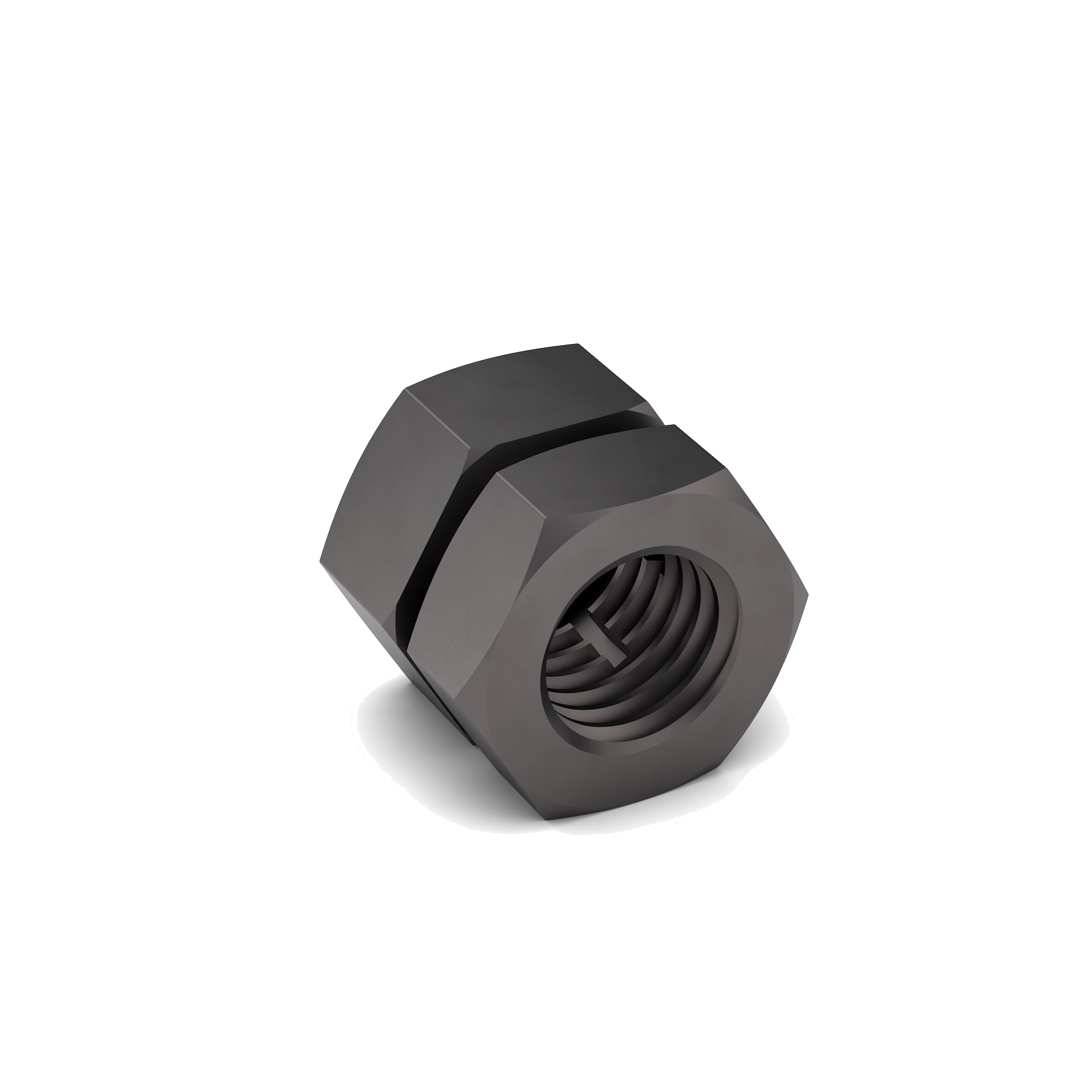

Distorted Thread Locknut

A distorted thread locknut is a type of prevailing torque locknut that resists loosening through mechanical friction created by intentional deformation of its threads. Unlike locknuts that rely on nylon inserts or adhesives, a distorted thread locknut uses metal-to-metal interference to maintain tension and prevent vibration-induced loosening.

The deformation is typically applied to the top portion of the nut—through methods such as oval shaping, elliptical compression, or a trilobular design—causing the threads to slightly distort from a perfect circle. When a bolt is threaded into the nut, the distorted section grips tightly against the bolt’s threads, generating frictional resistance that holds the assembly in place.

These locknuts are often made from all-metal materials such as carbon steel, stainless steel, or alloy steel, allowing them to withstand high temperatures and repeated reuse without degradation (unlike nylon-insert nuts, which can wear or melt). They are widely used in automotive, aerospace, rail, and heavy machinery applications where vibration, thermal cycling, or load reversals could otherwise cause standard nuts to back off.

Dog Point Hand Knob Screw

A dog point hand knob screw is a hand-tightened knob screw whose threaded stud ends in a short, cylindrical “dog” tip that is smaller than the thread major diameter and usually unthreaded with a flat end. The integral knob (phenolic or nylon plastic, over-molded, or metal) provides tool-free turning, while the dog point serves as a pilot that drops into a hole, slot, or bushing to start the screw straight. That pilot action speeds alignment, prevents cross-threading, and lets the screw act like a temporary locating pin as you draw parts together.

In use, the dog point is common on access panels, machine guards, jigs and fixtures, changeover hardware, and any setup that’s removed and refitted frequently. The tip guides into a mating feature so the first thread engages cleanly, it protects the leading threads from damage in blind holes, and it gives repeatable positioning when the same part is installed many times. Compared with cone- or cup-point tips, a dog point won’t dig in; it is meant to locate, not bite.

Typical constructions pair a plastic or metal knob with a steel or stainless stud; finishes for steel include zinc plating or black oxide, and some versions use brass or nylon dog tips to avoid marring softer materials. Dog-point length and diameter vary by manufacturer and application; the pilot is generally long enough to enter the mating hole before the first full thread engages, and the hole is sized slightly larger than the dog so it slips in easily. Length is measured from under the knob’s bearing face to the end of the dog tip.

Because these are hand-operated fasteners, they are intended for moderate clamping, not high preload or vibration-critical joints. If you need added security, pair the knob screw with a flat washer or shoulder under the knob, a lock washer or nylon-insert nut on the far side, or a pre-applied thread-locking patch on the threads.

Dog Point Screw

A dog point screw is a screw with a short, unthreaded cylindrical tip that extends beyond the threaded portion of the shank. Unlike sharp-tipped screws, the flat-ended “dog point” guides the screw into pre-drilled holes, ensuring proper alignment and reducing the risk of cross-threading. This makes them ideal for applications where precise positioning or repeated assembly and disassembly is required.

These screws are widely used in machinery, tooling, and fixtures, often serving as set screws or locating devices. The dog point can act as a stop, hinge, or locator pin, securing parts in place without damaging surfaces. They are especially common in assemblies involving rotating components like gears, pulleys, or shafts, where the point engages with a slot or hole to provide secure, reliable fastening.

Dolomite

Dolomite is a naturally occurring mineral and rock composed primarily of calcium magnesium carbonate, with the chemical formula CaMg(CO₃)₂. It is closely related to limestone, which is mainly calcium carbonate (CaCO₃), but dolomite contains significant magnesium, giving it distinct physical and chemical properties.

In its pure mineral form, dolomite appears as colorless to white or light gray crystals, often exhibiting a glassy to pearly luster. When found as a rock (dolostone), it typically occurs in sedimentary formations, often alongside or replacing limestone, formed through the chemical alteration of limestone by magnesium-rich groundwater in a process known as dolomitization.

Dolomite is valued for several reasons:

- Industrial use: It’s a key ingredient in the production of magnesium metal, glass, and ceramics, and it serves as a flux in steelmaking—helping remove impurities like silica and sulfur from molten metal.

- Construction material: Crushed dolomite rock is used as aggregate in concrete and asphalt and as base material for roads. It’s also used as dimension stone for decorative building facades and flooring.

- Agriculture: Finely ground dolomite, called dolomitic lime, is applied to soil to neutralize acidity and provide essential magnesium and calcium nutrients for plants.

- Environmental uses: It’s used in water treatment to adjust pH levels and reduce acidity.

Dolomite differs from limestone not only chemically but also in behavior—when treated with acid, limestone effervesces vigorously, while dolomite reacts much more slowly due to its magnesium content.

Dome Spring Washer

A dome spring washer is a type of spring washer with a semi-spherical or convex shape. It's also known as an umbrella washer or cup washer. Unlike flat washers, which only distribute a load, a dome spring washer functions as a spring, providing constant tension to a bolted assembly. This tension helps to prevent fasteners from loosening due to vibrations, thermal expansion, or contraction.

The key characteristics of a dome spring washer are its high load capacity and small deflection range. This makes it ideal for applications that require a strong clamping force but have limited space. Its unique shape allows it to absorb shocks and vibrations, which helps to maintain the tightness and integrity of an assembly. Additionally, it helps to control and maintain consistent tension, compensating for any changes in the material of the assembly.

Dome spring washers are similar to, but distinct from, Belleville washers (or conical spring washers). Both function as springs, but a dome spring washer has a smoother, rounded profile, whereas a Belleville washer has a more defined conical shape with a flat rim. Dome spring washers are better suited for applications that require a lower spring rate and more travel, making them excellent for shock absorption, while Belleville washers are designed for very high-load applications with minimal deflection.

Double End Bolt

A double end bolt (also known as a double-ended stud or tap-end stud) is a type of fastener that has threads on both ends but no head. It's typically used when one end is meant to be screwed into a tapped hole, while the other end extends outward to fasten with a nut.

Double End Pin Vise

A double end pin vise is a small, handheld precision tool used to grip and hold small cylindrical objects such as drill bits, wires, pins, rods, or taps for detailed manual work. It’s called double end because it has a chuck (or collet) on each end, typically of different sizes, allowing the user to switch between them depending on the diameter of the item being held—without needing to change tools.

The body of a double end pin vise is usually knurled metal, providing a non-slip grip for fine control during delicate operations. Inside each end is a collet—a slotted, tapered sleeve that tightens around the workpiece when the cap is screwed down. This design ensures a firm, centered hold on very small items, often in the range of 0.1 mm to 3 mm in diameter.

Double end pin vises are commonly used in jewelry making, electronics, watch repair, modeling, engraving, and precision machining, where a powered drill might be too aggressive or imprecise. They’re especially useful for hand drilling, tapping, reaming, or holding miniature components for inspection or assembly.

Double Expansion Shield Anchor

A Double Expansion Shield Anchor is a mechanical anchor used to securely fasten objects into brittle base materials like concrete, brick, or block, where expansion anchors might otherwise crack the material.

Double Shear

Double shear is a loading condition that occurs when a fastener such as a bolt, pin, or rivet is subjected to shear forces acting in two parallel planes. This means the load is distributed across two cross-sectional areas instead of one, allowing the fastener to resist higher loads than it would in single shear. Essentially, the fastener experiences two simultaneous shearing actions, which makes the connection stronger and more efficient.

In a single-shear joint, the bolt or pin is only sheared in one location, with the entire load acting on a single cross-section. In a double-shear joint, however, the load passes through two connected members, so the fastener is sheared in two places. Because the load is divided between two shear planes, each carries only half the total force, effectively doubling the joint’s shear capacity when the load is evenly distributed.

A simple example can be seen in bolted plate assemblies. If two plates are joined by a single bolt, that bolt is in single shear. If a third plate is added between them and the bolt passes through all three, the bolt is in double shear. This configuration provides greater strength and stability because it reduces the stress on each shear plane. In practical terms, double shear allows a joint to support more load without increasing the size of the fastener, making it a preferred design in many structural and mechanical applications.

Double Start Thread

A double-start thread is a type of screw thread that has two separate thread starts (or helical grooves) wrapped around the same cylinder, each offset by 180 degrees. This design means that there are two interleaved threads instead of one continuous helical ridge.

In a single-start thread, one full revolution of the fastener moves it forward by one thread pitch. In a double-start thread, each revolution advances the fastener twice the pitch distance, because both thread starts work together. The result is a much faster linear movement for the same number of rotations, while still maintaining strong engagement with the mating part.

Double-start threads are often used in applications where quick assembly or disassembly is required, or where a larger lead (axial travel per turn) is desired without making the thread pitch excessively large. They are common in bottle caps, screw-top containers, jackscrews, and certain precision instruments where controlled but rapid motion is beneficial.

However, because there are fewer engaged threads at any given point compared to single-start designs, double-start threads typically offer less load-carrying strength, so they are best suited for light- to moderate-load applications.

Dovetail Bolt

A dovetail bolt is a specialized fastener designed with a tapered or dovetail-shaped head that fits securely into a corresponding dovetail slot or groove. This unique shape prevents the bolt from rotating or pulling out once installed, allowing for strong, precise, and vibration-resistant connections—especially in applications where space is limited or where components need to be frequently assembled and disassembled.

The dovetail head design acts as a mechanical interlock, distributing load evenly and ensuring accurate alignment between parts. Once inserted into the dovetail slot, the bolt is typically secured with a nut on the threaded end, clamping the connected components tightly together.

Dovetail bolts are commonly used in machine tooling, fixturing systems, railway tracks, and precision equipment, where exact positioning and resistance to shear forces are essential. They are often made from high-strength alloy steel or stainless steel to handle heavy loads and wear.

Dovetail Nut

A dovetail nut is a specialized type of nut designed to slide into a dovetail groove or track, where it locks securely in place to provide a strong, fixed threaded anchor point. Its base is shaped like a dovetail—wider at the bottom and narrower at the top—allowing it to fit snugly within a matching dovetail slot and resist lifting or rotation when a bolt or screw is tightened into it.

This design provides precise alignment, high shear strength, and vibration resistance, making dovetail nuts ideal for applications where components need to be repeatedly adjusted or repositioned without losing stability. They are commonly used in machine tool tables, T-slot assemblies, rail systems, jigs and fixtures, and modular framing systems.

Most dovetail nuts are made from steel, stainless steel, or aluminum, depending on the required strength and corrosion resistance. Some versions include a spring-loaded ball or retention clip to hold them in position during assembly.

Dowel Pin

A dowel pin is a short, straight, cylindrical pin used to locate, align, or join two parts together with precise repeatability. Instead of carrying most of the load like a bolt, a dowel pin’s main job is positioning—making sure parts go together in exactly the same place every time.

In industrial and fastener terms, dowel pins are usually made from hardened steel, stainless steel, or precision-ground alloys and manufactured to very tight diameter tolerances. They are pressed or slipped into matching holes in mating parts (for example, two plates, a housing and a cover, or a shaft and a hub). When the parts are assembled, the pins keep them from shifting sideways, maintain alignment, and help absorb shear forces, while screws or bolts handle the clamping force.

You’ll see dowel pins used in machinery, automotive assemblies, gearboxes, fixtures, dies, molds, jigs, and precision equipment—anywhere accurate alignment is critical. Common examples include lining up engine components, aligning a machine base to a frame, or ensuring a fixture always returns to the same position on a machine table. They come in metric and inch sizes, in press-fit or slip-fit styles, and sometimes with special ends (chamfered, grooved, or threaded pull-ends) to aid installation and removal.

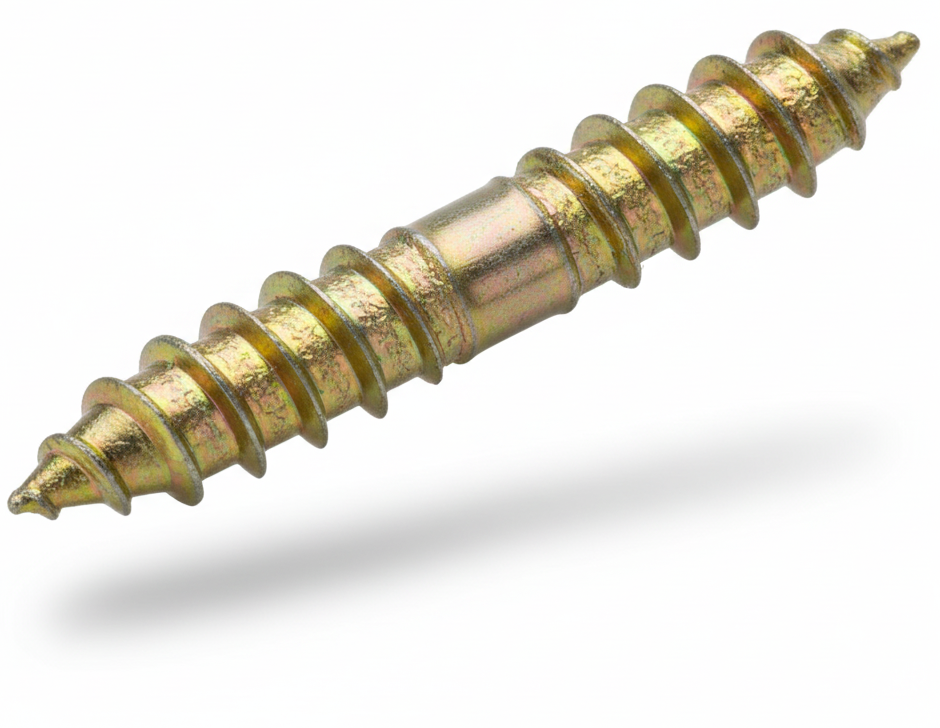

Dowel Screw

A dowel screw is a type of double-ended fastener that has wood screw threads on both ends and no head. It’s designed to join two pieces of wood together in a way that the fastener itself remains hidden. Because it has threads on both sides, each end can be screwed into a separate wooden component, creating a strong, invisible connection—often used in furniture making, cabinetry, and woodworking assembly.

One end of a dowel screw is typically inserted into a pre-drilled pilot hole in one wooden part using locking pliers or a driver bit that grips the center of the screw. The other part (for example, a leg or rail) is then screwed onto the exposed threaded end, effectively joining the two pieces. This allows for a tight, permanent joint without the need for nails, visible screws, or external hardware.

Dowel screws are most commonly used in table legs, stair balusters, newel posts, chair frames, and knock-down furniture joints. They are generally made of steel or stainless steel, and the threads are coarse to grip wood fibers securely.

Dowel Sleeve

A dowel sleeve is a protective or alignment component designed to house and support a dowel pin or dowel bar, ensuring proper positioning, movement allowance, or corrosion protection in mechanical or structural assemblies.

In mechanical and engineering applications, a dowel sleeve is often a thin-walled metal or plastic tube placed around a dowel pin to reduce friction, absorb vibration, or compensate for alignment tolerances. It allows for a precise fit between components that must align accurately but may require occasional disassembly or slight flexibility.

In construction and civil engineering, particularly in concrete slabs and pavements, a dowel sleeve (or dowel bar sleeve) is a plastic or steel casing that fits over one end of a dowel bar used to connect adjoining slabs. This sleeve allows the bar to move longitudinally (for expansion and contraction) while still transferring load between the slabs. It prevents the dowel from bonding to the concrete on one side, ensuring that the joint can expand and contract without cracking or structural stress.

Dowel sleeves are typically made from PVC, polyethylene, or steel, depending on whether flexibility, corrosion resistance, or structural strength is required.

AKA: Dowel Bar Sleeve

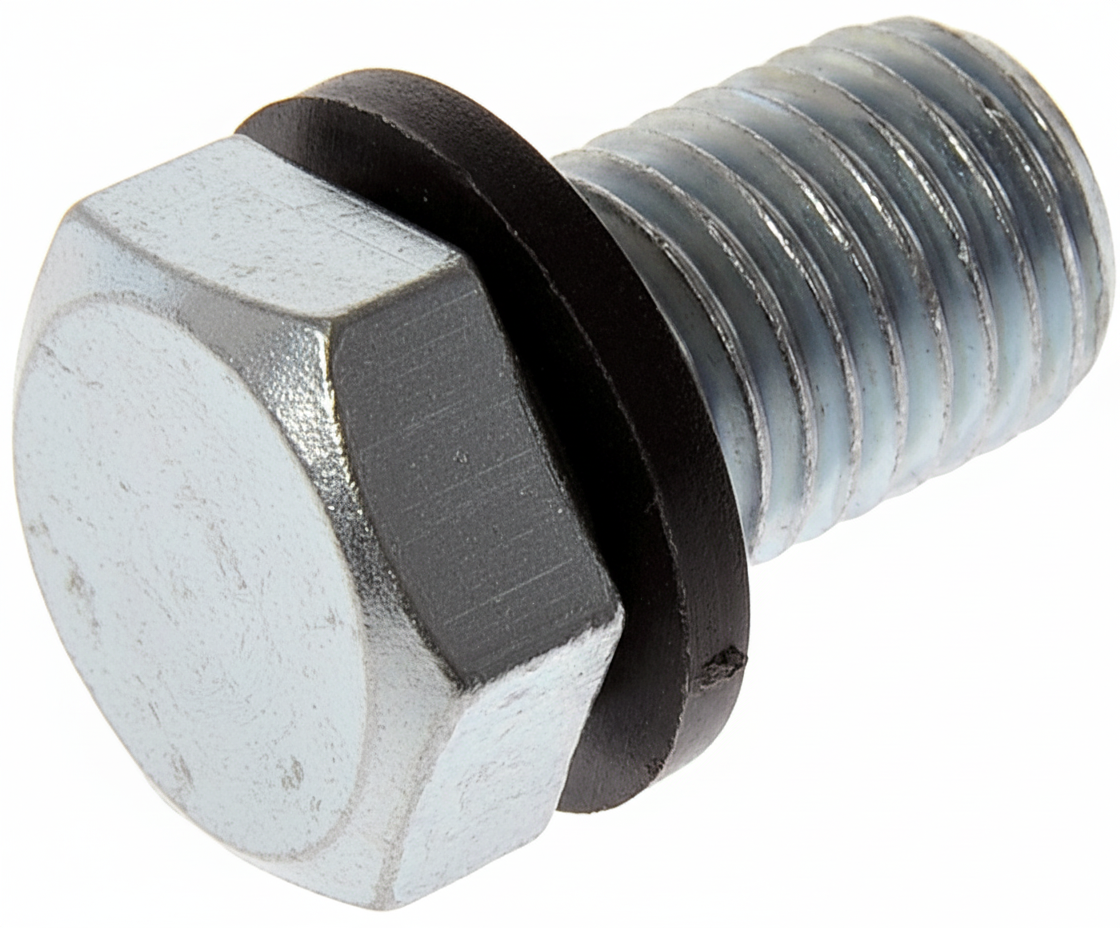

Drain Plug

A drain plug is a removable fastener designed to seal and allow controlled drainage of fluids—such as oil, coolant, or fuel—from an engine, gearbox, tank, or reservoir. It serves as both a seal to prevent leaks during operation and a service point to release fluids during maintenance or replacement.

Typically, a drain plug consists of a threaded bolt or screw that fits into a matching threaded hole at the lowest point of the container to ensure complete drainage. It often includes a sealing washer or gasket—made from materials like copper, nylon, or rubber—to prevent leaks. Some designs also feature magnetic tips to attract and capture metallic particles from the fluid, helping monitor wear in engines and transmissions.

Drain plugs are most commonly found in automotive oil pans, hydraulic systems, radiators, industrial machinery, and marine engines. They are made from durable materials such as steel, brass, aluminum, or stainless steel, depending on the application and fluid type.

Drake Lock Nut (2 piece)

Drake Two-Piece Lock Nuts, or Two-Piece Lock Nuts, are free-spinning two-piece lock nuts that can be positioned anywhere along the length of the thread. The two pieces give the nut double-locking action where the bottom nut’s flexible slotted crown digs into a male thread as the second nut is fastened on top. This action locks the nut, providing superior holding power compared to “prevailing torque” style lock nuts in high-vibration applications. These nuts can be found fastening air conditioning roof pads. Drake Two-Piece Lock Nuts are heat treated for Grade 5 applications.

Drawing

A detailed engineering or technical illustration that specifies the dimensions, shapes, tolerances, and features of a fastener. This drawing serves as the blueprint for manufacturing, inspection, and quality assurance to ensure the fastener meets all design and functional requirements.

Drive Rivets

Drive rivets are a type of mechanical fastener used to join or secure materials together, typically in thin sheets or soft materials like plastic, aluminum, or light metals. They are designed to be installed by driving the rivet into a pre-drilled hole using a hammer or a specialized tool.

Drive Style

In the context of fasteners like bolts and screws, the drive style is the shaped recess or protrusion on the head of the fastener. This is the part of the fastener designed to accept a specific tool, such as a screwdriver or wrench, to apply torque for tightening or loosening. The drive style is a fundamental characteristic of a fastener, and its design has a direct impact on the tool you need and how the fastener performs.

The choice of a drive style is important because it dictates several key factors. First, it determines how much torque can be applied to a fastener without damaging it. Second, it affects cam-out, which is when the tool slips out of the recess. Drives with better cam-out resistance allow for more efficient power tool use and reduce the chance of stripping the fastener head. Finally, some drive styles are designed for specific applications, such as for security or aesthetics, requiring a specialized tool to prevent tampering.

Here are a few of the most common drive styles and their key features:

Slotted: The oldest and simplest design, it has a single slot and is prone to cam-out, making it unsuitable for high-torque applications.

Phillips: This is the most common drive. The cross-shaped recess was originally designed to intentionally cam-out at a certain torque to prevent over-tightening.

Torx (Star): With a six-pointed star shape, this drive offers superior cam-out resistance and can handle very high torque, making it popular in the automotive and electronics industries.

Hex Socket (Allen): This style features a hexagonal recess that is driven by an Allen key. It's well-suited for high-torque needs and is commonly found in machinery and furniture.

Robertson (Square): A square-shaped recess that provides excellent grip and is highly resistant to cam-out. It's a favorite in woodworking because the tapered shape can hold the screw on the driver.

Drop Forged Bolt

A drop forged bolt is a type of high-strength fastener manufactured through the drop forging process, which shapes the bolt by hammering heated metal into a die under high pressure. This method refines the metal’s internal grain structure, aligns it along the shape of the bolt, and eliminates voids or internal defects—resulting in superior mechanical strength, toughness, and fatigue resistance compared to bolts made by machining or casting.

In drop forging, a heated steel blank (usually medium- or high-carbon steel, or alloy steel) is placed between two shaped dies. When the dies close and the hammer strikes, the metal flows into the mold cavity, forming the bolt head precisely while maintaining a dense, uniform microstructure. After forging, the bolt is trimmed, heat-treated, and threaded.

Drop forged bolts are commonly used in heavy-duty applications such as construction, mining, railway, agriculture, and structural steelwork, where extreme loads, vibration, or impact forces are present. Typical examples include eyebolts, anchor bolts, U-bolts, and crane bolts.

Drum Bolt

An industrial drum bolt is a high-strength fastener used to secure and stabilize components of industrial drums, barrels, or rotating drum assemblies found in heavy machinery and processing equipment. These bolts are engineered to handle intense mechanical stress, vibration, and rotational forces, ensuring structural integrity and reliable performance. Commonly made from heat-treated carbon steel or high-grade alloys, they are often used in cement mixers, conveyors, kilns, and storage drums to fasten flanges, lids, or drive components. Their design may include coarse threads or locking features to resist loosening during operation, making them essential for maintaining the safety and durability of heavy-duty industrial systems.

Drum Wing Screw

A drum wing screw is a type of hand-tightened fastener featuring a wing-shaped head and a threaded shank, designed for easy manual installation and removal without tools. The “drum” designation typically refers to its common use in securing or assembling drums, containers, machinery panels, or access covers where frequent opening and closing is required.

The wing head—shaped like two opposing flanges or “wings”—provides a large gripping surface, allowing the user to apply torque by hand. This makes the screw ideal for quick adjustments or fastening in low-torque applications. The drum variant may include design modifications such as shorter thread lengths, larger heads, or specific coatings (like zinc or stainless finishes) to improve grip, corrosion resistance, or compatibility with metal and plastic drum fittings.

Drywall Nails

Drywall nails are specialized nails designed specifically for attaching drywall (also called plasterboard or gypsum board) sheets to wood or metal framing studs during wall and ceiling construction.

Dual Hex Chainring Bolt

A Dual Hex Chainring Bolt is a type of fastener specifically designed for securing bicycle chainrings to the crankset spider. The term “dual hex” refers to the fact that both sides of the bolt— the bolt head and the nut—have hexagonal sockets, allowing a hex key (Allen wrench) to be inserted into each side simultaneously. This design prevents the nut from spinning while the bolt is being tightened or loosened, making installation and removal much easier and more secure.

Typically made from steel, aluminum, or titanium, dual hex chainring bolts consist of two parts: the male bolt and the female nut. The male portion threads into the female side, clamping the chainring tightly against the crank arm. Because both sides are hex-shaped, the fastener offers better torque control and reduces the risk of stripping, which is common with single-sided chainring bolts that rely on friction or special tools to hold the nut in place.

These bolts are common in high-performance bicycles, particularly road and mountain bikes, where precise torque and reliability are critical. The dual hex design ensures a tighter, more stable connection, minimizing loosening or creaking during pedaling.

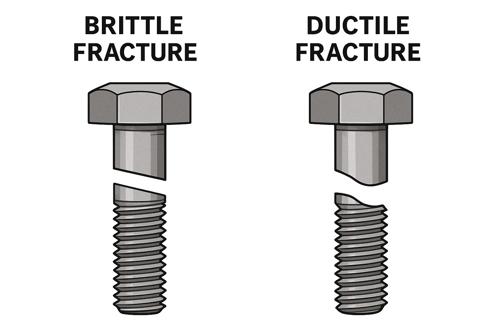

Ductile Fracture

A ductile fracture is a type of material failure that occurs when a material is subjected to stress and undergoes significant plastic deformation before breaking. Unlike brittle fracture, which happens suddenly with little warning, ductile fracture is a more gradual process where the material stretches, bends, or elongates as it absorbs energy prior to failure.

The process of ductile fracture typically occurs in stages. First, the material deforms elastically (reversible stretching), then plastically (permanent deformation). As the load increases, localized thinning or “necking” develops at the weakest point. Microscopic voids form and grow inside the material, eventually coalescing into cracks. The final break often occurs along a slanted plane, and the fracture surface usually appears rough and fibrous rather than flat and smooth.

One of the key characteristics of ductile fracture is the warning it provides before failure. Because the material shows visible signs of distortion—such as stretching, necking, or elongation—engineers can often detect and address the problem before catastrophic collapse. This makes ductile materials safer for critical applications.

Ductile fracture is commonly observed in materials such as mild steel, aluminum, copper, and many alloys. It is generally considered a desirable failure mode in engineering because it indicates toughness, energy absorption, and resistance to sudden breakage.

Ductility

Ductility is the ability of a material to deform plastically—usually by stretching, bending, or drawing—without breaking. It measures how much a material can elongate under tensile stress before it fractures. A ductile material can be pulled into thin wires or undergo significant shape changes while maintaining its strength and cohesion.

This property is especially important in metals and alloys, such as steel, copper, aluminum, and gold, which can endure large amounts of deformation during forming processes like rolling, extrusion, or forging. Ductility is commonly quantified by the percentage of elongation or reduction in area in a tensile test, where higher values indicate a more ductile material.

Ductile materials tend to absorb more energy before failure, making them safer and more reliable in structures or machinery that experience impact or vibration. In contrast, brittle materials—like cast iron or ceramics—fracture suddenly with little to no plastic deformation.

Duplex Lug Nut

A duplex lug nut is a two-piece fastener system designed to provide smooth installation, better alignment, and consistent clamping force—commonly used in heavy-duty vehicles, trailers, and industrial equipment where durability and precision are critical. It consists of an inner nut (or washer section) and an outer nut (or shell) that rotate independently.

The inner portion threads directly onto the wheel stud and provides the primary clamping force, while the outer sleeve or shell allows for smooth tightening without galling or damaging the wheel surface. This design helps ensure even torque distribution and makes it easier to remove or adjust the nut under heavy loads or repeated use. The dual-piece structure also helps prevent seizing and reduces wear between the nut and wheel.

Duplex lug nuts are typically made from hardened steel and may feature protective coatings such as zinc, chrome, or phosphate plating for corrosion resistance. They’re especially common on commercial trucks, off-road vehicles, and agricultural machinery, where vibration, dirt, and torque variation can otherwise compromise fastening reliability.

Duplex Nail

A duplex nail is a construction nail with a distinctive double head design that makes it easy to install and remove. The lower head is driven flush with the work surface, while the second, raised head remains exposed above the material. This exposed head allows builders to quickly pull the nail out with a hammer or pry bar once the temporary structure is no longer needed.

Because of this design, duplex nails are widely used in temporary construction work such as concrete formwork, scaffolding, and bracing. They provide solid holding power during use but save significant time and effort during teardown, making them a practical choice for jobs that require both strength and easy removal.

Duplex Plating

Duplex plating is a two-layer metal coating system designed to combine the advantages of two different protective finishes to achieve superior corrosion resistance, durability, and appearance. The process involves applying two distinct coatings—usually one metallic layer followed by another complementary one—that work together to protect the underlying substrate, often steel or iron.

A common example of duplex plating is nickel-chrome plating, where a layer of nickel is first applied for its corrosion resistance, smoothness, and adhesion, followed by a thin layer of chromium for hardness, wear resistance, and a bright decorative finish. Another example is zinc-nickel plating followed by a chromate or organic topcoat, often used in automotive and aerospace applications for enhanced protection against rust and oxidation.

The key advantage of duplex plating lies in the synergistic effect between the two coatings. The inner layer provides barrier and corrosion protection, while the outer layer acts as a sacrificial or protective shield, reducing exposure to the environment and extending the life of the coating system.

Duplex Screw

A duplex screw is a temporary fastener commonly used in construction, featuring a distinctive double head design. The lower head sits against the work surface, while the raised second head remains accessible for easy removal with a screwdriver or drill.

This design makes duplex screws ideal for applications like concrete formwork, bracing, and scaffolding, where strong holding power is required but the fasteners will eventually be taken out. They provide the strength of a screw with the convenience of quick removal, helping save time and reduce damage to materials during disassembly.

Duplex Stainless Steel

Duplex stainless steel is a type of stainless steel that combines the properties of both austenitic and ferritic stainless steels within a single microstructure. Its name comes from this “dual-phase” composition — roughly 50% austenite and 50% ferrite — which gives it an exceptional balance of strength, toughness, and corrosion resistance. This hybrid structure provides advantages that neither phase can achieve alone, making duplex stainless steels highly valued in demanding industrial environments.

Chemically, duplex stainless steels typically contain 19–28% chromium, 3–10% nickel, and 0.05–0.5% nitrogen, with possible additions of molybdenum, copper, and tungsten to enhance corrosion resistance. The nitrogen and molybdenum are especially important for improving resistance to pitting, crevice corrosion, and chloride-induced stress corrosion cracking, which are major weaknesses of austenitic and ferritic grades when used alone.

Mechanically, duplex stainless steels are about twice as strong as common austenitic grades like 304 or 316, while maintaining good ductility and impact toughness. They have excellent resistance to chloride stress corrosion cracking, a property inherited from their ferritic phase, and superior general and localized corrosion resistance due to their high chromium and molybdenum content. Their reduced nickel content also makes them more cost-stable, as they are less affected by fluctuations in nickel prices.

Common grades include 2205 (UNS S32205/S31803), the most widely used standard duplex stainless steel, and 2507 (UNS S32750), a “super duplex” grade with higher alloy content and even greater corrosion resistance. Duplex stainless steels are widely used in chemical processing, oil and gas production, desalination plants, pulp and paper manufacturing, marine environments, and structural applications where strength and corrosion resistance are critical.

In summary, duplex stainless steels offer a unique combination of high strength, corrosion resistance, and cost efficiency, bridging the gap between austenitic and ferritic grades. Their dual-phase structure gives them the ability to withstand harsh chloride environments, high mechanical loads, and thermal stresses, making them one of the most versatile materials used in modern industrial design.

Dye penetrant testing (PT)

Dye Penetrant Testing (PT) is a non-destructive testing (NDT) method used to reveal surface-breaking flaws such as cracks, seams, laps, porosity, and leaks in both metallic and non-metallic materials. It works on any non-porous material—including metals, plastics, ceramics, and composites—making it more versatile than magnetic particle testing. The process begins with careful surface preparation to remove dirt, grease, paint, or other contaminants that could block the penetrant. A liquid dye, usually either visible red or fluorescent under ultraviolet light, is applied to the cleaned surface and allowed to dwell long enough to seep into any open defects by capillary action.

After the dwell time, excess penetrant is carefully cleaned from the surface while ensuring the dye remains inside the cracks or pores. A white developer is then applied, which acts like a blotter by drawing the trapped dye back out of the flaws, creating a strong contrast between the flaw indication and the background. Under proper lighting—white light for visible dyes or UV light for fluorescent penetrants—inspectors can see the indications clearly and evaluate the location, size, and nature of the discontinuities. PT is widely used across aerospace, automotive, energy, and manufacturing industries for inspecting welds, castings, forgings, and machined parts. While it is sensitive, inexpensive, and easy to apply, PT is limited to detecting only surface-breaking flaws, requires thorough cleaning before and after testing, and depends heavily on inspector skill for accurate interpretation.

Dynamic Load

A dynamic load on fasteners is a force that changes in magnitude or direction over time, contrasting with a constant and steady static load. Because these loads fluctuate, they put a different, more complex kind of stress on a fastener than a static load does. Dynamic loads can originate from a variety of sources, including vibrations from machinery, sudden impacts, or repeated cyclic forces. An understanding of dynamic loading is critical for engineers, who must design systems that can endure these forces without failing.

How dynamic loads affect fasteners

The effects of dynamic loads pose significant challenges to fastener integrity. Constant vibration or fluctuating forces can cause a fastener to lose its preload, which is the clamping force that holds a joint together. If this preload decreases, the fastener can gradually loosen. This is particularly problematic in situations with repeated, back-and-forth applications of force, known as fatigue or cyclic loading. Over time, these cyclic stresses can cause micro-cracks to form in the fastener's material, which can eventually lead to a sudden and catastrophic fatigue failure, even at stress levels below the fastener's maximum tensile strength. Dynamic loads can also cause stress concentration in certain areas of a bolted joint, increasing the risk of failure at those specific points due to uneven force distribution.

Methods for mitigating dynamic load effects

Engineers and designers employ several strategies to prevent fastener failure from dynamic loads. To prevent fasteners from vibrating loose, locking mechanisms are used, such as thread lockers, locknuts, or toothed washers. For applications involving high-cycle fatigue, chemical-based adhesive anchors can provide a strong bond capable of handling repeated movement. Another approach is to design the overall joint to be more rigid than the fastener itself, which shifts the burden of dynamic forces onto the joint, thereby reducing the stress placed directly on the fasteners. These methods are crucial for ensuring the reliability and safety of components subjected to fluctuating forces.

Dzus Fastener

A Dzus fastener (pronounced “zoose”) is a type of quick-release fastener designed to provide secure and rapid attachment and removal of panels, covers, or components—without the need for tools. It consists of a spring receptacle mounted on one part (usually the frame or structure) and a slotted stud on the removable panel. When the stud is pushed in and turned a quarter turn (typically 90 degrees), it locks into the spring, creating a firm, vibration-resistant connection.

Dzus fasteners are widely used in aviation, motorsports, and industrial equipment, where frequent access to panels or components is needed for inspection, maintenance, or adjustments. Their design allows for consistent clamping force, resistance to vibration loosening, and repeated use without loss of performance.

They come in several types, including flush-head, wing-head, and button-head styles, and are commonly made from steel, stainless steel, or aluminum, depending on strength and corrosion resistance requirements.