Resources

Glossary

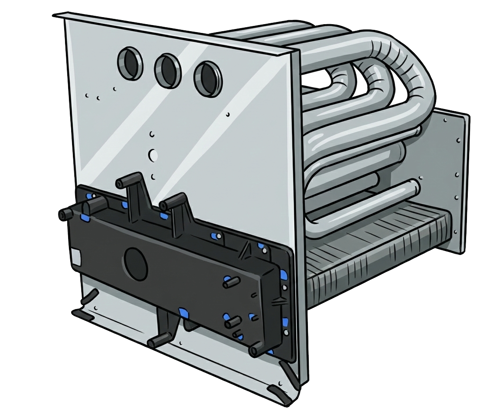

Heat Exchanger

A heat exchanger is a piece of industrial equipment that transfers heat from one fluid to another (liquid-to-liquid, gas-to-gas, or gas-to-liquid) without the fluids mixing in normal operation. Heat flows through a thermally conductive barrier (typically metal tubes or plates), driven by the temperature difference between the hot and cold streams, so one stream is cooled while the other is heated.

In chemical and industrial service, heat exchangers are used for process heating and cooling, condensing vapors, evaporating/boiling liquids, heat recovery (capturing waste heat to improve efficiency), and temperature control for reactors, distillation systems, and utilities. Common designs include shell-and-tube exchangers (a bundle of tubes inside a shell), plate-and-frame exchangers (stacked plates with gaskets), air-cooled exchangers (fans moving air over finned tubes), and double-pipe exchangers (one pipe inside another).

From a fastening and joint-sealing perspective, heat exchangers often rely on bolted covers, channel heads, flanges, and pass partitions that must maintain gasket seating stress under pressure and thermal cycling. That makes correct selection and installation of bolting, nuts, washers, and gasket types (e.g., spiral wound or kammprofile in many services) critical to prevent leakage, especially as temperature changes cause differential expansion and preload changes.