Resources

Glossary

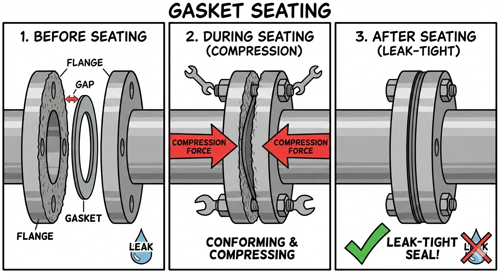

Gasket Seating

Gasket seating is the process by which a gasket is compressed and conformed between two mating surfaces during bolt-up so it creates a continuous, leak-tight seal. As the fasteners are tightened, the joint applies compressive stress that causes the gasket to flow, crush, or deform (depending on gasket type), filling in surface roughness, waviness, and minor imperfections so there are no continuous leakage paths.

Gasket seating typically happens in two stages: an initial seating phase during tightening where the gasket’s thickness reduces and its contact area stabilizes, and a short-term settlement/relaxation phase afterward where additional compression loss can occur due to creep, cold flow, embedment, and surface “bedding-in.” This is why gasketed joints are often tightened in multiple passes and patterns and may require a relaxation pass (retorque) after a dwell period to restore lost bolt load and maintain the gasket stress needed for sealing.

The amount of gasket seating required depends on gasket construction (soft sheet, spiral wound, kammprofile, PTFE, graphite, etc.), flange surface finish, temperature, and internal pressure, and it’s often managed by specifying a minimum gasket seating stress (sometimes expressed as a seating factor in design methods) to ensure the gasket is sufficiently compressed without being over-crushed or damaged.