Resources

Glossary

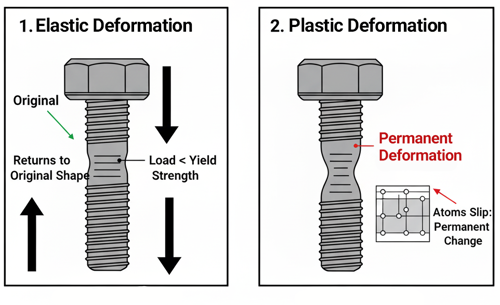

Plastic Deformation

Plastic deformation is the permanent change in shape or size of a material that occurs when it is subjected to a stress beyond its elastic limit or yield strength. In this state, the material no longer returns to its original form after the load is removed, unlike during elastic deformation where the shape fully recovers. Plastic deformation happens when the applied stress causes atoms within the material’s crystal structure to move or slip past each other, resulting in a lasting rearrangement of the internal structure.

In metals, plastic deformation often begins gradually once the yield strength is exceeded and continues until fracture. During this process, the metal stretches, compresses, or bends without breaking, which is why it’s a key property in manufacturing processes such as forging, rolling, bending, and drawing. The ability of a material to undergo plastic deformation before breaking is called ductility.

For example, when a bolt is tightened past its yield strength, it begins to stretch permanently — its diameter may slightly reduce, and the threads might elongate. If the load continues to increase, the bolt eventually “necks” and fractures. This behavior demonstrates the material’s transition from elastic to plastic deformation, showing how stress can permanently alter its geometry.

In summary, plastic deformation represents the irreversible flow of a material under stress, where it maintains its new shape even after the load is removed. It’s a crucial concept in understanding how metals and other materials behave under real-world mechanical forces and why design limits are based on avoiding excessive plastic strain that can lead to failure.