Resources

Glossary

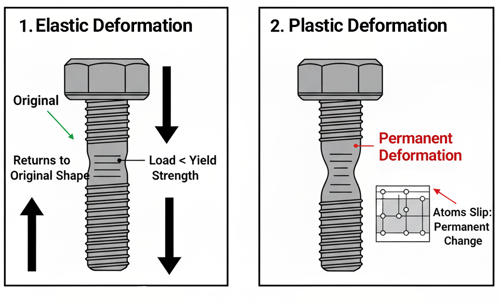

Elastic Deformation

Elastic deformation is the temporary change in shape or size of a material that occurs when an external force or stress is applied, but the material returns to its original shape once the force is removed. It happens within the material’s elastic limit, meaning the internal atomic bonds are stretched or compressed but not permanently rearranged. The relationship between stress and strain in this region follows Hooke’s Law, which states that the deformation is directly proportional to the applied load.

In simpler terms, when a force is applied to a bolt, spring, or metal rod, it may elongate or compress slightly, but once the load is removed, it returns to its initial length and form. This behavior occurs because the atomic structure of the material only experiences reversible displacements—the bonds between atoms act like tiny springs that stretch and recover.

Elastic deformation is a critical concept in engineering and materials science because it defines the safe working range of a material. Designers and engineers ensure that fasteners, beams, and machine components operate below their elastic limit to prevent permanent deformation or failure. When the stress exceeds this limit, the material enters the plastic deformation stage, where changes become irreversible.

In summary, elastic deformation is a reversible, proportional response to stress, allowing materials to absorb energy and return to their original form once the load is released. It represents the phase before permanent, plastic deformation begins.