Resources

Glossary

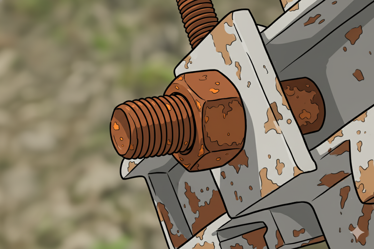

Corrosion (Metallic Corrosion)

Metallic corrosion is the gradual degradation of a metal through a chemical or electrochemical reaction with its environment, resulting in the conversion of the metal into more stable compounds such as oxides, hydroxides, or sulfides. In essence, it is the reversion of refined metal back to its natural, ore-like state—for example, iron rusting back into iron oxide.

Corrosion occurs because most metals exist in a high-energy, unstable state after refining from their ores. When exposed to oxygen, water, acids, salts, or other reactive substances, they naturally tend to return to a lower-energy, oxidized form. The most common and damaging type of metallic corrosion is electrochemical corrosion, which involves the flow of electrons between anodic (oxidizing) and cathodic (reducing) sites on the metal’s surface.

Here’s how it happens:

1. At the anode, metal atoms lose electrons and form positive metal ions — for example:

Fe → Fe²⁺ + 2e⁻

This is oxidation, and it’s the site of metal loss.

2. At the cathode, a reduction reaction occurs, often involving oxygen and water, such as:

O₂ + 2H₂O + 4e⁻ → 4OH⁻

3. The electrons released at the anode travel through the metal to the cathode, completing the circuit. The metal ions produced at the anode can react further with oxygen or water to form corrosion products like iron oxide (rust).

Environmental factors such as humidity, temperature, pH, and salt concentration greatly influence the rate of corrosion. For example, saltwater accelerates corrosion by increasing electrical conductivity, while acidic environments promote metal ion dissolution.

There are several types of metallic corrosion, including:

- Uniform corrosion, where the surface degrades evenly (common in steel rusting).

- Galvanic corrosion, which occurs when two dissimilar metals are electrically connected in an electrolyte, causing one to corrode preferentially.

- Pitting corrosion, a localized attack that produces small but deep holes.

- Crevice corrosion, which occurs in shielded or tight areas where oxygen levels are low.

- Intergranular and stress corrosion cracking, which occur along grain boundaries or under tensile stress in corrosive environments.

Prevention and control of corrosion rely on barrier coatings (paint, plating, galvanizing), cathodic protection, corrosion-resistant alloys (like stainless steel, titanium, or Inconel), and environmental control (e.g., desiccation or pH adjustment).