Resources

Glossary

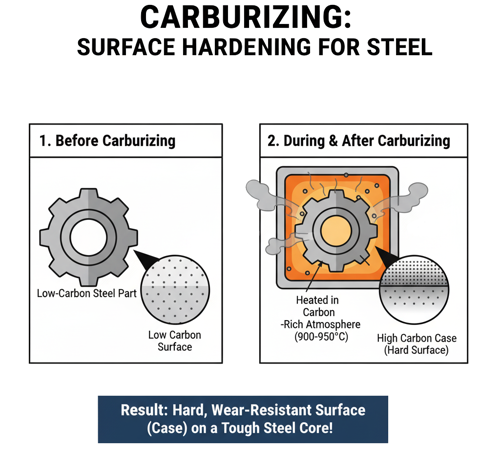

Carburizing

Carburizing is a thermochemical heat treatment process used to increase the carbon content of the surface layer of low-carbon steel or iron. During this process, a metal part is heated to the austenitizing temperature—typically 900–950°C (1650–1750°F)—in the presence of a carbon-rich environment, such as a gas (e.g., methane or carbon monoxide), liquid (molten salt bath), or solid (charcoal or carbon powder).

At this temperature, the steel’s crystal structure transforms into austenite, which has a high solubility for carbon. Carbon atoms diffuse into the surface layer of the metal over time, gradually forming a carbon-enriched zone known as the carburized case. The depth of this case depends on how long the metal is exposed to the carbon-rich atmosphere—typically ranging from a few tenths of a millimeter to several millimeters.

After the desired carbon diffusion is achieved, the part is quenched (rapidly cooled) to transform the carbon-rich austenitic surface into martensite, a hard, wear-resistant microstructure. The result is a component with a hard, high-carbon surface and a tough, low-carbon core. This dual property makes carburized parts highly resistant to wear, fatigue, and surface deformation while maintaining resistance to shock and impact.

Carburizing is just one method within the broader category of case hardening, which includes other surface-hardening processes such as nitriding, carbonitriding, cyaniding, and flame or induction hardening. While all case hardening techniques create a hardened outer layer over a softer interior, carburizing specifically relies on carbon diffusion at high temperature to form the case.