Resources

Glossary

Ductility

Ductility is the ability of a material to deform plastically—usually by stretching, bending, or drawing—without breaking. It measures how much a material can elongate under tensile stress before it fractures. A ductile material can be pulled into thin wires or undergo significant shape changes while maintaining its strength and cohesion.

This property is especially important in metals and alloys, such as steel, copper, aluminum, and gold, which can endure large amounts of deformation during forming processes like rolling, extrusion, or forging. Ductility is commonly quantified by the percentage of elongation or reduction in area in a tensile test, where higher values indicate a more ductile material.

Ductile materials tend to absorb more energy before failure, making them safer and more reliable in structures or machinery that experience impact or vibration. In contrast, brittle materials—like cast iron or ceramics—fracture suddenly with little to no plastic deformation.

Head Ductility Block Test

The Head Ductility Block Test is a mechanical test used to evaluate the ductility and toughness of a nail’s head, ensuring it can withstand deformation without cracking or breaking. This test focuses specifically on the head portion of the nail, since nail heads often endure repeated hammer impacts during installation and must resist splitting or flaking.

In the test, the nail is driven into or against a ductility block, which is usually a hardened steel or standardized block fixture. As the nail is struck, the head deforms under controlled loading conditions. The nail is then examined to see whether the head remains intact, develops cracks, or separates from the shank. The degree of deformation the head can undergo before failure indicates its ductility.

The purpose of the Head Ductility Block Test is to ensure that nails have sufficient malleability to handle installation forces without losing structural integrity. A brittle head might crack or shear off, which could compromise fastening strength and safety.

This test is often used in nail manufacturing quality control to verify material properties, heat treatment processes, and overall performance standards. It helps ensure nails meet industry requirements for durability in real-world applications such as construction, carpentry, and structural fastening.

Tensile Ductility Test

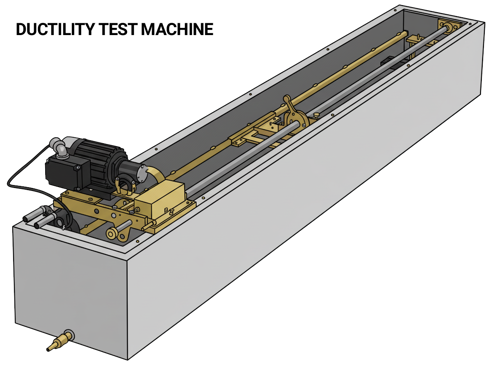

A Tensile Ductility Test is a standardized method used to measure how well a material can stretch, elongate, and undergo plastic deformation under a pulling force before it breaks. It provides key information about the ductility, toughness, and overall performance of a material when subjected to tension.

During the test, a specimen such as a machined metal rod, fastener, or another standardized piece is placed in a tensile testing machine. The machine gradually applies a pulling force along the specimen’s axis until the material deforms and eventually fractures. Throughout the test, important data is recorded, including the elongation of the specimen, which shows how much it lengthens as a percentage of its original length, the reduction of area at the fracture point caused by necking, and the full stress-strain behavior, which illustrates the relationship between applied stress and strain from the yield strength through the ultimate tensile strength and finally to fracture.

The purpose of the Tensile Ductility Test is to evaluate how a material responds when exposed to tensile loads. Materials with high tensile ductility, such as mild steel or aluminum, are able to stretch significantly before breaking, while more brittle materials like cast iron or hardened steel fracture with very little elongation.

This type of test is widely used in fastener manufacturing, structural engineering, and materials science. For fasteners in particular, it ensures that bolts, screws, and other components have the toughness required to deform safely without failing suddenly under load, thereby verifying their reliability in real-world applications.