What Does It Mean When a Fastener Is Case Hardened?

What Does It Mean When a Fastener Is Case Hardened?

In fastener manufacturing, heat treatments play a major role in determining how a part performs in the field. These processes are often used to manipulate the hardness level, strength level, and ductility of a fastener, depending on the requirements of the application or the end user.

One common and cost-effective method for increasing a fasteners durability is called case hardening. This process increases a fastener’s surface durability while preserving its elasticity.

But what exactly does that mean?

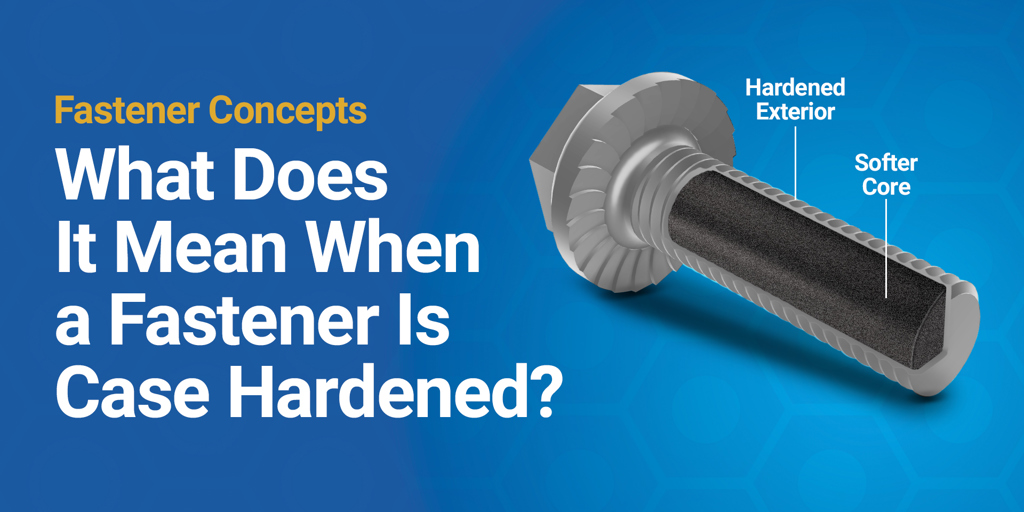

Case hardening is a process that hardens only the outer surface of a steel part. The inside of the fastener, sometimes referred to as its core, remains soft while retaining its ductility. This combination provides a wear-resistant exterior that protects against abrasion, while the softer core remains ductile and helps prevent cracking or brittle failures when the fastener is in use.

This heat treatment process typically involves heating the fastener in a carbon- or nitrogen-rich environment. At high temperatures, these elements diffuse into the surface layer of the steel. When the part is cooled, the added carbon or nitrogen creates a hardened microstructure in the outer layer. This makes the exterior significantly harder than the softer, untreated core beneath it. In most cases, the hardened layer is only a few thousandths of an inch thick, but it’s enough to greatly improve the fastener’s wear resistance.

Fasteners that are case hardened are often used in situations where the threads or outer surface see a lot of repeated use, like with tapping screws, wood screws, pins, rivets, or hex flange screws. While these parts aren’t typically designed for high-load applications, they perform exceptionally well in conditions where thread integrity and surface durability are essential.

The benefit of case hardening is that it strikes a balance between durability and cost. It provides a hard, wear-resistant surface that protects the threads from damage, while the softer core remains ductile to prevent cracking or brittle failures. This makes case hardened fasteners a practical and cost-effective solution for a wide range of everyday fastening applications.

Understanding how case hardening works will help ensure you're sourcing fasteners that meet your customers' performance and reliability expectations. If you need support identifying or sourcing case-hardened fasteners, our team is here to help. Call us at 800-327-6378 or email us at [email protected].