Ask the expert: A tale of two fine threads

Question: Why do 1” diameter hex head cap screws have a different “fine” thread than 1” diameter socket head cap screw (1”-14 vs 1”-12)?

Answer: When we are asked this question it is usually from a customer that ordered the wrong thread pitch when they ordered a 1-inch diameter “fine” threaded nut or screw. It is also a question that I do not have a good answer as to why this one size has three thread pitches associated with it:

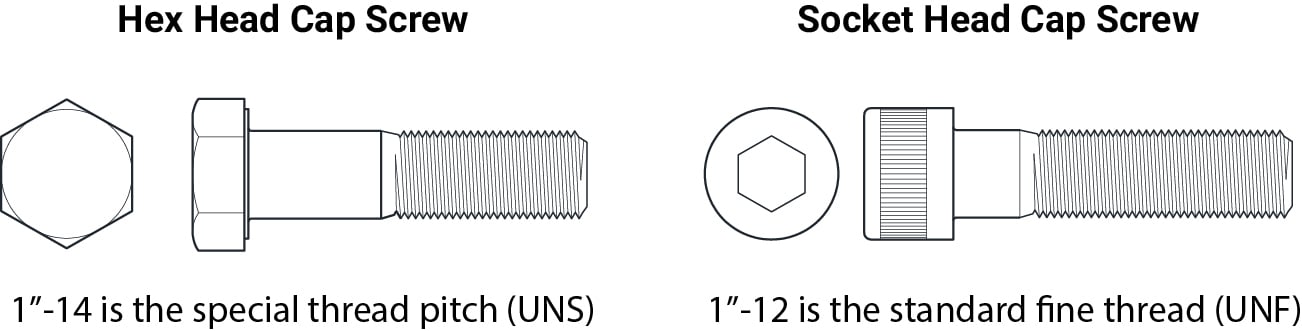

1”-8 is the standard coarse thread (UNC)

1”-12 is the standard fine thread (UNF)

1”-14 is the special thread pitch (UNS)

Up until the late 1940’s, the 1”-14 thread was the standard “fine” thread in the U.S for 1” diameter bolts and screw. When the Unified National (UN) thread standards were developed after World War II between the U.S, Canada, and Great Britain, the 1”-12 thread was made the standard fine thread (UNF) for 1” diameter bolts, screws and nuts (per ANSI/ASME B1.1). The 1”-14 thread was included in the standard but it is listed as a “special” thread (UNS).

To this day, the most commonly stocked “fine” threaded hex head cap screw is the 1”-14 thread. While the most commonly stocked “fine” threaded socket head cap screw is the 1”-12 thread. Earnest does stock hex cap screws and hex nuts with a 1”-12 thread but we sell more 1”-14 product than we do 1”-12.

The main challenge for our customers is when their customer just asks for a 1” fine threaded hex bolt or hex nut. The average mechanic can look a bolt and see that it has a fine thread (as compared to the standard coarse thread of 1”-8) but unless they measured the threads with a gage they will not know if they need a 12 threads per inch nut or a 14 threads per inch nut. If your customer asks you for a 1” fine threaded product (or they even callout a 1” UNF thread) I believe you need to ask them to verify the thread pitch they are looking for. For the majority of applications that we sell hex nuts and hex cap screw into, the 1”-14 thread is the most popular but we do run into applications where they want the 1”–12 thread. So you need to ask your customer to verify which thread pitch they want when they just ask for a 1” fine threaded nut or bolt.

As to the reason why the majority of hex cap screws and hex nuts continue to be made with the 1”-14 thread and the majority of socket head cap screws are made with a 1”-12 thread is a mystery to me.

Technically a bolt with a 1”-14 thread is “stronger” than a bolt with a 1”-12 thread. A grade 8 (150,000 psi min tensile strength) hex cap screw with a 1”-14 thread has a minimum ultimate tensile load of 101,900 lbs while a grade 8 with a 1”-12 thread has a minimum ultimate tensile load of 99,400 lbs. At this level, I am not sure the extra 2,500 lbs is all that significant. The flip side to this is that the actual strength of a 1”-14 threaded nut is lower than the strength of a 1”-12 nut. The thread shear area for a 1”-12 nut is 2.27 in2. The thread shear area for a 1”-14 nut is 2.23 in2. The minimum load required to shear the threads on a 1”-14 grade 8 nut would be 128,000 lbs and for a 1”-12 grade 8 nut it would be 130,752 lbs. Again I don’t think the load difference of 2,750 lbs is significant, both nuts can easily support the max load of the corresponding strength level bolt.

One story that I have heard is that the 1”-14 thread is popular in the locomotive industry, and as we all know the locomotive industry is slow to change (I don’t think that locomotive engineers even know that the hex head caps screws has been invented yet, we still sell more square heads to this industry than any other).

Let me know if you have heard any reasons as to why the 1”-14 (UNS) thread is more popular for hex head bolts and hex nuts and the 1”-12 (UNF) thread is more popular with socket head cap screws.