Ask The Expert: What is meant by the term “lock nut?”

Answer:

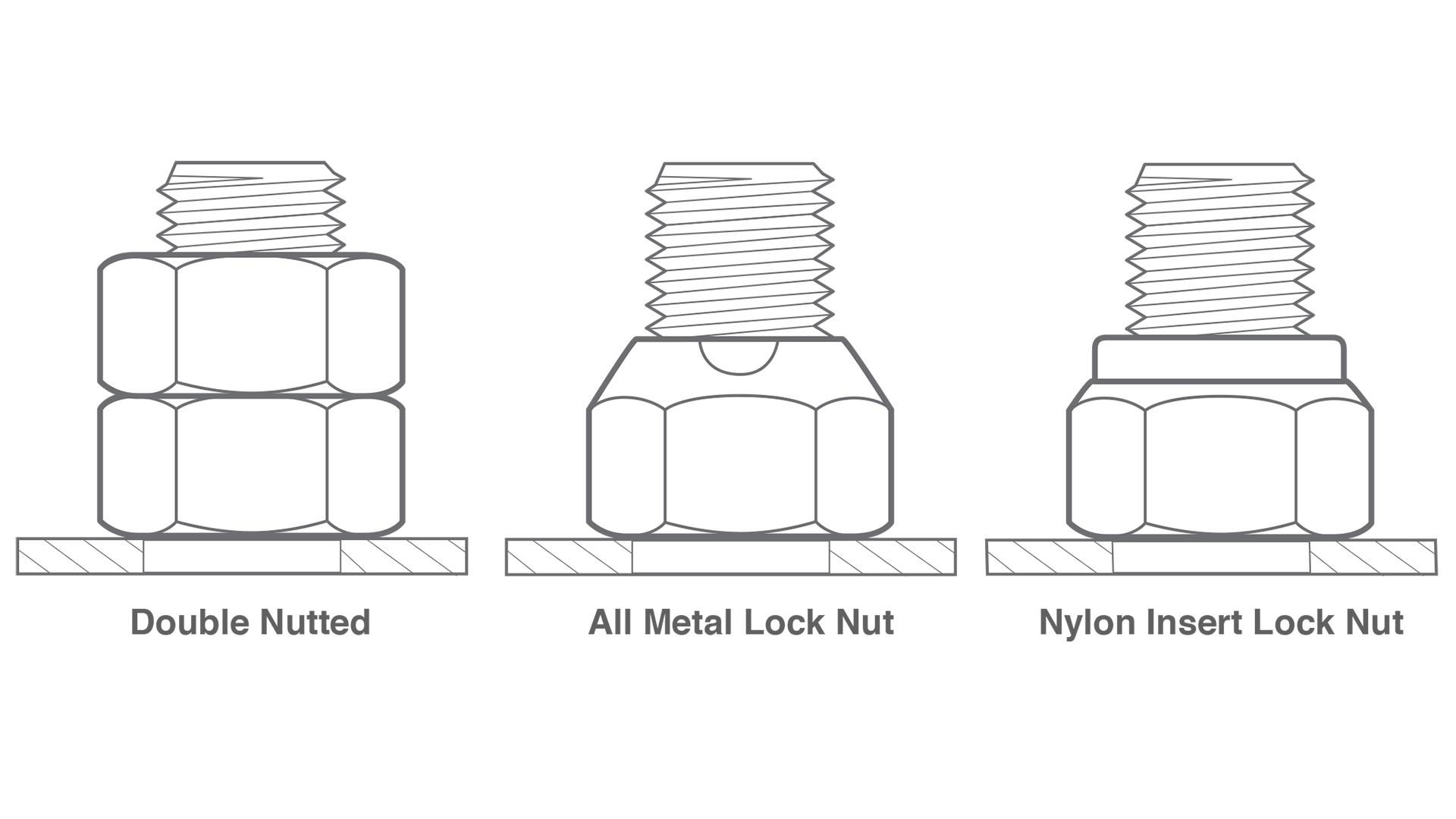

Historically, when designers wanted to ensure that an assembly did not come loose, they would require that the bolt be “double-nutted”. Double nutting is an effective way of preventing an assembly from loosening, but it is not the most cost-effective way.

Nut manufacturers have developed nuts that are designed to eliminate the need for double-nutting. These styles of nuts are called “lock nuts”. A lock nut is typically a hex nut that has a built in feature that increases the nut’s resistance to loosening. These types of nuts are commonly called “prevailing torque” lock nuts because they require the use of a wrench to run the nut down the thread of the bolt (they are not “free-spinning” like a standard hex nut).

Lock nuts typically fall into two categories:

1. All-Metal Lock Nuts

• The most common design is a nut with a crowned top (looks like an upside down wheel nut).

• The crowned top is crimped to create a prevailing torque feature that increases the nut’s resistance to loosening.

• Common names for all-metal lock nuts are: Top Lock, Conical Lock, Tri-Lock, Stover locknut, Griptite Locknut

2. Nylon Insert Lock Nuts

• This style of lock nut has a non-metallic (nylon) ring encased into the top of the nut.

• When this style of nut is assembled onto the bolt thread, the nylon will distort and grip onto the bolt thread.

• The compressed nylon then keeps the nut from backing off in high vibration applications.

• Common names for nylon insert lock nuts are: Nylock Nut, Non-metallic Insert Nut, Stop Nut