Getting what you pay for

|

Earnest Machine has a 65-year history of providing only high-quality parts sourced from manufacturers that meet our strict quality standards, helping you rest assured on the quality we provide in every high-grade product we sell. Our vendor process is rigid — sometimes taking up to a year before we determine a manufacturer can produce parts at the consistency and at the quality we demand. We visit the factories and evaluate the machinery, the manufacturing processes, and the raw materials used. Once a manufacturer passes our new vendor certification program, each lot of parts we accept is inspected to ensure quality standards are being met — all to provide you peace of mind in the quality of the products you purchase from Earnest Machine. Earnest Machine is here to help you source quality parts along with a variety of service programs designed to help you succeed. Here are a few things to look for when sourcing plow and carriage bolts this year. |

||||

Head Marking: Head markings allow you to identify and trace a part back to a manufacturer. If the manufacturer isn’t proud to put their mark on it, why would you want to sell it? Every high-quality part from Earnest has a head marking to allow for traceability. We only sell products from manufacturers whose product quality meets our strict guidelines and are proud to show it with a head marking. |

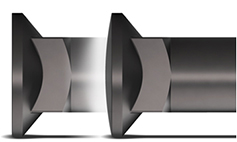

Feed Thickness: The feed area is the flat area that comprises the edge of the bolt head. As a bolt wears, the feed thickness diminishes. Think of it as the head slowly disappearing. With less head gripping the blade, the bolt assembly loosens, resulting in failure of the bolt and potential damage to the blade. Earnest’s #3 Domed Head Plow Bolts are specifically designed with the maximum amount of feed area thickness to ensure maximum wear and longevity. Domed Head Plow Bolts meet CAT standards and are available in Grade 8 and Grade E9-170m. |

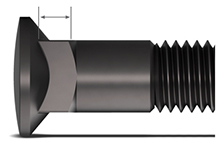

Square Depth: The square of a plow or carriage bolt is the square part of the bolt directly under the head. This part fits into the square opening of the blade and through the mold or plow board, then is secured with a washer and nut to join the two parts together. Inconsistent manufacturing practices can result in varying thicknesses of this area, causing the bolt to slip or spin out of the hole, resulting in part failure, blade damage, or worse, damage to the board. |

||

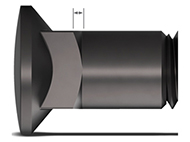

Rolled Threads: Our plow and carriage bolts are roll threaded, compressing the steel to form the thread. This compression retains and enhances the strength of the bolt and creates a better defined root radius. The fully defined root radius makes a stronger thread and reduces the likelihood of thread fatigue failures. |

Fillet Radius: Look for parts that have a well-defined fillet radius — the transition area below the square into the body of the bolt. Fluctuations in the machining of this critical stress area can result in “head popping,” where the head of the part literally pops off of the bolt. |

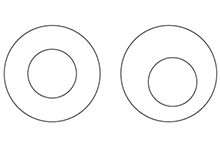

Concentricity of Threads: Thread concentricity is the alignment of the thread to the center point of the head. Inconsistent manufacturing of parts can result in deviations of thread concentricity, leading to binding during installation and part failure. |

||

Certifications: Earnest engineers and sourcing specialists review certifications to confirm steel quality and heat-treating standards are being met. Every part you order should have corresponding certification documents — if they’re not in the box, they should at the least be made available to you. Quality is everything, and we are not afraid to prove it. We make sure our certs (or MTRs) are accurate, legible, and show you the build specification of the part you order. No questions about it. Our cert library stems back 20 years and is made available at anytime you need it, free of charge through our website. |

Alloy Steel: Earnest Grade 8 and E9-170m plow bolts are made of high strength alloy steels that are harder, stronger and resist wear and corrosion better than carbon steel. Earnest only sources Grade 8 and E9-170m plow bolts from manufacturing regions that have mastered the process of creating high-grade alloy steel. Our engineering team translates Manufacturing Test Reports (MTR’s) to ensure the steel mix and process meets industry standards and ours as well. |

Uniform Heat Treating: Heat treating is the process of exposing a part to extreme heat, in turn adding strength to the finished product when it cools. Making sure parts are heat treated to industry specifications can be a challenge for some manufacturers. Old or inferior equipment or attention to heating times can directly effect the strength and quality of the end product. Earnest only works with manufacturers that take quality as serious as we do and proves it through detailed Manufacturing Testing Reports indicating heat treating process, time and temperatures. |

||

|

|

||||